Varial Foam: Revolutionizing Surfboard Performance and Beyond

In the world of surfboard construction, innovation is a constant pursuit. Among the advancements, Varial foam stands out as a game-changer, offering superior performance characteristics compared to traditional polyurethane (PU) and expanded polystyrene (EPS) foams. This article delves into the properties, benefits, applications, and future of Varial foam, exploring why it’s becoming increasingly popular among surfers and shapers alike.

What is Varial Foam?

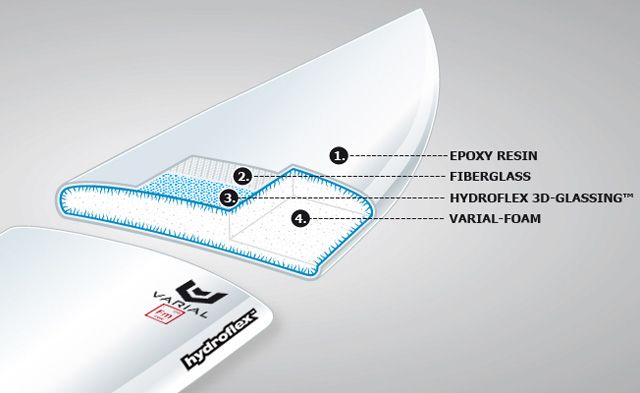

Varial foam, also known as Infused Matrix Technology (IMT), is a closed-cell, aerospace-grade foam developed specifically for surfboard construction. Unlike traditional foams, Varial foam is infused with a resin matrix under high pressure and temperature, creating a material with exceptional strength, durability, and responsiveness. This unique manufacturing process results in a foam that is significantly denser and more resistant to water absorption than PU or EPS.

Key Properties and Benefits of Varial Foam

Superior Strength and Durability

One of the most significant advantages of Varial foam is its exceptional strength-to-weight ratio. The infusion process creates a dense, rigid structure that can withstand significant impact and stress without compromising the board’s overall weight. This translates to surfboards that are less prone to dings, dents, and breakage, extending their lifespan and reducing the need for frequent repairs. Surfers can push their limits without worrying about their board failing under pressure.

Enhanced Responsiveness and Performance

Varial foam’s high density and rigidity contribute to enhanced responsiveness and performance in the water. The foam transmits energy more efficiently, allowing surfers to generate speed and power with greater ease. This results in a more direct and connected feel between the surfer and the wave, enabling tighter turns, quicker acceleration, and improved overall control. The improved responsiveness is a key reason many professional surfers are switching to boards constructed with Varial foam.

Minimal Water Absorption

Water absorption is a major concern for surfboard materials, as it can significantly impact the board’s weight, performance, and longevity. Varial foam boasts a closed-cell structure and resin infusion, making it highly resistant to water absorption. This means that even if the outer fiberglass layer is compromised, the foam core will remain relatively dry, preventing the board from becoming waterlogged and heavy. This is a critical advantage in maintaining consistent performance over time.

Consistent Flex Characteristics

The manufacturing process of Varial foam allows for precise control over its density and flex characteristics. This enables shapers to fine-tune the board’s flex pattern to suit specific surfing styles and wave conditions. Whether a surfer prefers a stiff, responsive board for high-performance surfing or a more forgiving, flexy board for cruising, Varial foam can be tailored to meet their individual needs. This consistency ensures that each board performs as intended, providing a reliable and predictable ride.

Environmentally Conscious Manufacturing

While not entirely sustainable, Varial foam production often incorporates more environmentally conscious practices compared to traditional foam manufacturing. The closed-cell structure reduces the release of volatile organic compounds (VOCs) during shaping and glassing, minimizing air pollution. Additionally, some manufacturers are exploring the use of recycled materials in the resin infusion process, further reducing the environmental footprint. As sustainability becomes increasingly important, the industry is likely to see even more eco-friendly innovations in Varial foam production.

Applications of Varial Foam

While primarily used in surfboard construction, the unique properties of Varial foam make it suitable for a range of other applications:

- Stand-Up Paddleboards (SUPs): The strength and durability of Varial foam make it an excellent choice for SUPs, which are often subjected to significant stress and impact.

- Kiteboards: The responsiveness and water resistance of Varial foam are ideal for kiteboards, allowing riders to perform high-performance maneuvers with confidence.

- Sailboards: The stiffness and lightweight properties of Varial foam can enhance the performance of sailboards, improving speed and control.

- Aerospace Components: The aerospace-grade nature of Varial foam makes it suitable for certain non-structural aerospace applications where weight and strength are critical considerations.

Varial Foam vs. Traditional Surfboard Foams

To fully appreciate the benefits of Varial foam, it’s helpful to compare it to the two most common types of surfboard foam: polyurethane (PU) and expanded polystyrene (EPS).

Varial Foam vs. Polyurethane (PU)

PU foam has been the industry standard for decades, known for its smooth feel, ease of shaping, and relatively low cost. However, PU foam is heavier than Varial foam and more susceptible to water absorption. It also tends to be less durable and more prone to dings and dents. Varial foam offers superior strength, responsiveness, and water resistance compared to PU, making it a worthwhile upgrade for surfers seeking enhanced performance and longevity. [See also: Surfboard Materials: A Comprehensive Guide]

Varial Foam vs. Expanded Polystyrene (EPS)

EPS foam is lighter and more buoyant than PU, making it a popular choice for small-wave boards and boards designed for beginners. However, EPS is generally less durable than PU and more prone to cracking. It also lacks the smooth feel and responsiveness of PU. Varial foam bridges the gap between PU and EPS, offering a lightweight yet durable alternative with superior responsiveness and water resistance. While more expensive than EPS, Varial foam’s performance benefits often justify the investment. [See also: EPS vs PU Surfboards: Which is Right for You?]

The Future of Varial Foam

As technology advances and demand for high-performance surfboards grows, Varial foam is poised to play an increasingly important role in the surfing industry. Ongoing research and development efforts are focused on further improving its strength, durability, and environmental sustainability. We can expect to see:

- Increased use of recycled materials: Manufacturers are actively exploring ways to incorporate recycled plastics and bio-based resins into the Varial foam production process, reducing its environmental impact.

- Advanced shaping techniques: CNC (Computer Numerical Control) shaping machines are becoming more sophisticated, allowing for precise and intricate board designs with Varial foam.

- Customized foam densities: Shapers will have greater control over the density and flex characteristics of Varial foam, enabling them to create highly customized boards tailored to individual surfer preferences.

- Wider adoption in other industries: The unique properties of Varial foam may lead to its adoption in other industries, such as aerospace, automotive, and marine, where lightweight, strong, and water-resistant materials are needed.

Conclusion

Varial foam represents a significant advancement in surfboard construction, offering superior strength, responsiveness, and water resistance compared to traditional foams. While it may come at a higher price point, the performance benefits and extended lifespan of Varial foam surfboards make them a worthwhile investment for serious surfers. As technology continues to evolve, we can expect to see even more innovative applications of Varial foam, further solidifying its position as a leading material in the surfing industry and beyond. The future looks bright for this revolutionary foam, promising to push the boundaries of surfboard performance and design.