Unveiling Varial Foam: A Deep Dive into Its Properties, Applications, and Future

In the ever-evolving world of materials science, innovation is key. One such innovation making waves across various industries is varial foam. But what exactly is varial foam, and why is it gaining so much attention? This article provides a comprehensive overview of varial foam, exploring its unique properties, diverse applications, manufacturing processes, and the future trends shaping its development. We’ll delve into the science behind this versatile material, examining its composition and how it differs from traditional foam materials. Understanding varial foam is crucial for professionals and enthusiasts alike, as its potential impact spans from aerospace to consumer goods.

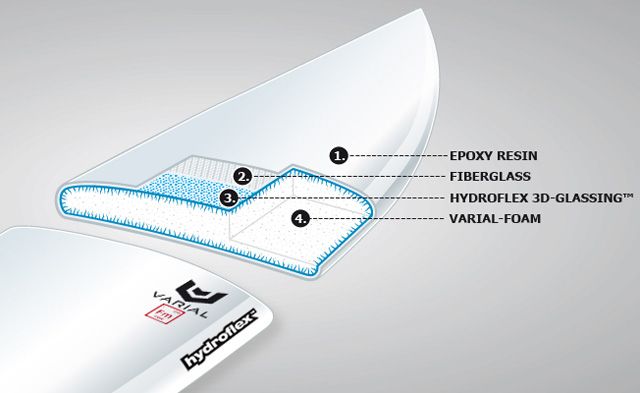

What is Varial Foam?

Varial foam is a specialized type of closed-cell foam known for its exceptional strength-to-weight ratio, superior impact resistance, and customizable density. Unlike conventional foams, varial foam is engineered with a unique cellular structure that allows for precise control over its mechanical properties. This control is achieved through advanced manufacturing techniques and the use of specific polymers, resulting in a material that can be tailored to meet the demands of a wide range of applications. Its closed-cell structure also contributes to its excellent buoyancy and water resistance, making it suitable for marine and aquatic environments. The term ‘varial’ refers to the variability in its properties, a key advantage that sets it apart from other foam materials.

Key Properties of Varial Foam

Several key properties define varial foam and contribute to its widespread adoption:

- High Strength-to-Weight Ratio: Varial foam offers remarkable strength while remaining lightweight, making it ideal for applications where weight reduction is critical.

- Impact Resistance: Its closed-cell structure effectively absorbs and dissipates impact energy, providing excellent protection against collisions and shocks.

- Customizable Density: The density of varial foam can be precisely controlled during manufacturing, allowing for tailored performance characteristics.

- Water Resistance: The closed-cell structure prevents water absorption, making it suitable for marine and aquatic environments.

- Thermal Insulation: Varial foam provides excellent thermal insulation, helping to regulate temperature and reduce energy consumption.

- Chemical Resistance: It exhibits resistance to a wide range of chemicals, ensuring its durability and longevity in harsh environments.

- Buoyancy: Due to its low density and closed-cell structure, varial foam offers exceptional buoyancy.

Applications of Varial Foam Across Industries

The unique properties of varial foam have led to its adoption across a diverse range of industries:

Aerospace and Aviation

In aerospace, varial foam is used in aircraft interiors, structural components, and insulation due to its lightweight nature, high strength, and thermal resistance. It helps reduce overall aircraft weight, improving fuel efficiency and performance. [See also: Advanced Materials in Aerospace]

Marine and Aquatic Applications

The buoyancy and water resistance of varial foam make it ideal for boat hulls, flotation devices, and marine structures. It provides reliable buoyancy and protection against water damage, even in harsh marine environments.

Sports and Recreation

Varial foam is used in surfboards, kayaks, and other sporting equipment to provide buoyancy, impact resistance, and structural support. Its customizable density allows for tailored performance characteristics to meet the specific needs of different sports.

Automotive Industry

In the automotive industry, varial foam is used in interior components, seating, and structural reinforcement to improve safety, comfort, and fuel efficiency. Its impact resistance helps protect occupants in the event of a collision.

Construction and Infrastructure

Varial foam is used in insulation panels, structural supports, and roofing materials in the construction industry. Its thermal insulation properties help reduce energy consumption and improve building efficiency.

Medical and Healthcare

The biocompatibility and customizable properties of varial foam make it suitable for medical implants, prosthetic devices, and cushioning materials. It can be tailored to provide support and comfort for patients with various medical conditions.

Packaging and Shipping

Varial foam is used in protective packaging to safeguard delicate and valuable items during shipping and handling. Its impact resistance and cushioning properties prevent damage and ensure safe delivery.

Manufacturing Processes of Varial Foam

The manufacturing of varial foam involves several key processes:

- Polymer Selection: The choice of polymer(s) is crucial, as it determines the final properties of the foam. Common polymers used include polyurethane, polyethylene, and polypropylene.

- Blowing Agent Incorporation: A blowing agent is added to the polymer mixture to create gas bubbles, which form the cellular structure of the foam. These can be physical or chemical blowing agents.

- Mixing and Molding: The polymer mixture and blowing agent are thoroughly mixed and then molded into the desired shape.

- Curing and Expansion: The mixture is then cured, causing the blowing agent to expand and create the closed-cell structure of the foam.

- Finishing and Quality Control: The finished foam is then subjected to quality control checks to ensure that it meets the required specifications. This includes testing for density, strength, and other relevant properties.

Advantages of Using Varial Foam

The benefits of using varial foam are numerous:

- Versatility: Varial foam can be tailored to meet the specific requirements of a wide range of applications.

- Performance: Its superior strength-to-weight ratio, impact resistance, and thermal insulation provide enhanced performance compared to conventional foams.

- Durability: Varial foam is resistant to water, chemicals, and other environmental factors, ensuring its longevity and reliability.

- Sustainability: Some varial foam formulations can be made from recycled materials, contributing to a more sustainable future.

- Cost-Effectiveness: While the initial cost may be higher than some traditional materials, the long-term benefits of varial foam, such as reduced weight, improved performance, and increased durability, can lead to significant cost savings.

Challenges and Considerations

Despite its numerous advantages, there are also challenges and considerations associated with the use of varial foam:

- Cost: The initial cost of varial foam can be higher than that of conventional foams.

- Manufacturing Complexity: The manufacturing process requires specialized equipment and expertise.

- Environmental Impact: The production of some varial foam formulations can have environmental impacts, although efforts are being made to develop more sustainable options.

- Recyclability: Recycling varial foam can be challenging, although research is ongoing to develop more effective recycling methods.

Future Trends in Varial Foam Technology

The future of varial foam technology is promising, with several key trends shaping its development:

- Sustainable Formulations: Researchers are developing varial foam formulations that use recycled materials and bio-based polymers to reduce their environmental impact.

- Advanced Manufacturing Techniques: New manufacturing techniques, such as 3D printing and additive manufacturing, are being used to create varial foam with even more complex geometries and tailored properties.

- Smart Foams: Researchers are exploring the integration of sensors and other electronic components into varial foam to create “smart” foams that can monitor their own condition and provide real-time feedback.

- Nanomaterial Reinforcement: The incorporation of nanomaterials, such as carbon nanotubes and graphene, can further enhance the strength and other properties of varial foam.

Conclusion

Varial foam represents a significant advancement in materials science, offering a unique combination of strength, lightweight properties, and customizable performance characteristics. Its diverse applications across various industries, from aerospace to sports equipment, demonstrate its versatility and potential. While challenges remain, ongoing research and development efforts are paving the way for more sustainable and advanced varial foam technologies. As industries continue to demand lighter, stronger, and more versatile materials, varial foam is poised to play an increasingly important role in shaping the future of materials science. The continued development and refinement of varial foam promise even greater innovation and application possibilities in the years to come. [See also: Future of Foam Materials]