Unlocking Comfort and Performance: A Deep Dive into Varial Foam Technology

In the ever-evolving world of materials science, particularly within the realm of sporting goods and footwear, innovation is the name of the game. One such innovation making waves is Varial foam. This advanced material is engineered to provide superior comfort, enhanced performance, and increased durability compared to traditional foams. This article will explore the intricacies of Varial foam, examining its composition, benefits, applications, and future potential.

What is Varial Foam?

Varial foam is a closed-cell foam material, typically composed of polyurethane or polyethylene, but often enhanced with proprietary additives and manufacturing processes. Unlike conventional foams, Varial foam is designed for specific performance characteristics, such as enhanced cushioning, improved energy return, and reduced weight. The term “Varial” itself implies variability and customization, highlighting the ability to tailor the foam’s properties to meet the demands of diverse applications.

The Science Behind Varial Foam’s Performance

The unique properties of Varial foam stem from its carefully engineered cellular structure. The closed-cell design prevents water absorption, making it ideal for use in wet or humid environments. Furthermore, the density and resilience of the foam can be precisely controlled during manufacturing, allowing engineers to fine-tune its performance characteristics. This control enables the creation of foams that are both highly responsive and exceptionally durable. [See also: Closed-Cell Foam Applications]

Key Characteristics:

- High Resilience: Varial foam exhibits excellent rebound properties, providing energy return and reducing fatigue.

- Lightweight: Despite its durability, Varial foam is remarkably lightweight, minimizing added bulk and improving overall performance.

- Water Resistance: The closed-cell structure prevents water absorption, ensuring consistent performance even in wet conditions.

- Customizability: The properties of Varial foam can be tailored to meet specific application requirements, including density, hardness, and color.

- Durability: Varial foam is highly resistant to wear and tear, ensuring long-lasting performance.

Applications of Varial Foam

The versatility of Varial foam has led to its adoption across a wide range of industries and applications. From athletic footwear to protective gear, this advanced material is enhancing performance and improving user experience.

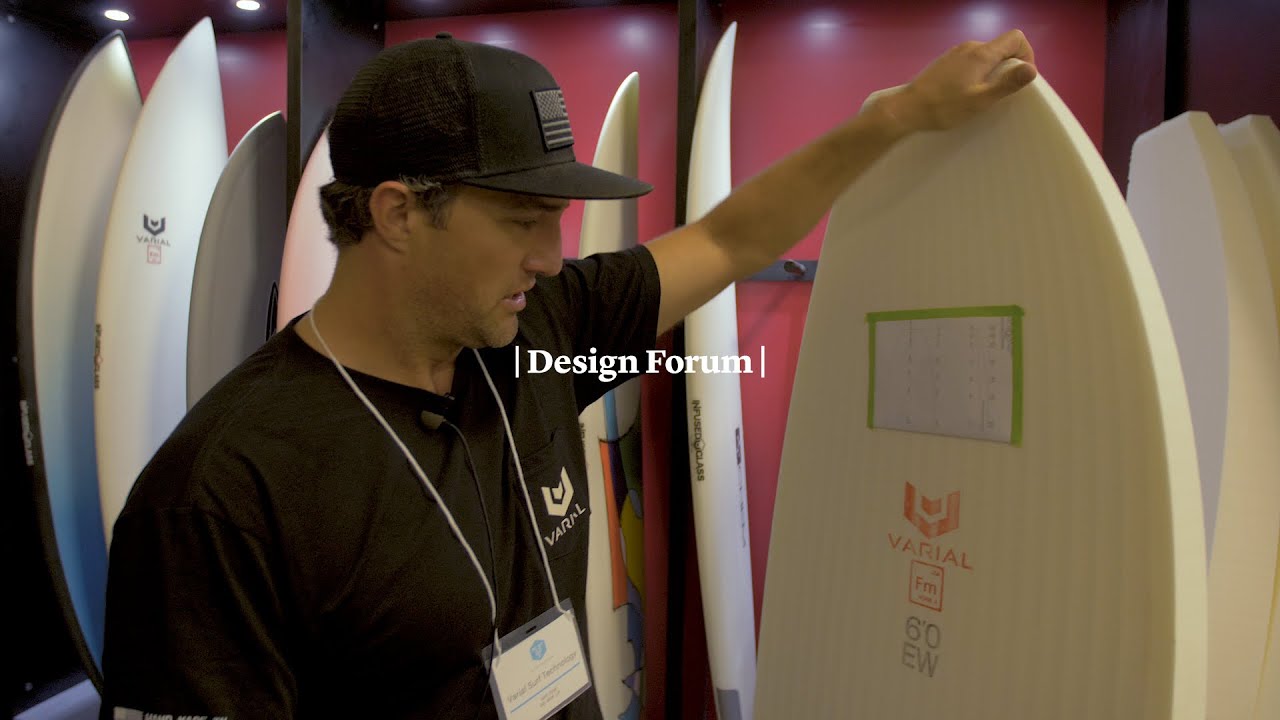

Sporting Goods

One of the primary applications of Varial foam is in sporting goods, particularly footwear. Its cushioning and energy return properties make it ideal for use in running shoes, basketball shoes, and other athletic footwear. The lightweight nature of the foam also helps to reduce the overall weight of the shoe, improving agility and reducing fatigue. Beyond footwear, Varial foam is also used in protective gear, such as helmets and padding, to provide impact absorption and protection. Its water resistance makes it suitable for water sports equipment, such as surfboards and wakeboards. [See also: Performance Footwear Technology]

Medical Applications

In the medical field, Varial foam is used in orthotics, prosthetics, and medical cushions. Its ability to provide customized support and pressure relief makes it ideal for these applications. The hypoallergenic properties of some Varial foam formulations also make it suitable for use in direct contact with skin. Furthermore, its closed-cell structure helps to prevent the growth of bacteria and fungi, reducing the risk of infection.

Industrial Uses

Varial foam finds applications in various industrial settings, including packaging, insulation, and vibration damping. Its cushioning properties make it ideal for protecting delicate items during shipping and handling. Its insulation properties help to reduce heat transfer, improving energy efficiency. Its vibration damping properties help to reduce noise and vibration, creating a more comfortable and productive work environment.

Consumer Products

Varial foam is increasingly being used in consumer products, such as mattresses, pillows, and furniture cushions. Its ability to provide customized support and pressure relief makes it ideal for these applications. The durability of Varial foam also ensures long-lasting comfort and support. Furthermore, its resistance to moisture and allergens makes it a hygienic choice for bedding and furniture.

Benefits of Choosing Varial Foam

The advantages of using Varial foam are numerous and compelling, making it a preferred choice for manufacturers and consumers alike.

- Enhanced Comfort: Provides superior cushioning and support, reducing pressure points and improving overall comfort.

- Improved Performance: Enhances energy return and reduces fatigue, leading to improved athletic performance.

- Increased Durability: Resistant to wear and tear, ensuring long-lasting performance and value.

- Reduced Weight: Lightweight design minimizes added bulk and improves agility.

- Water Resistance: Prevents water absorption, maintaining consistent performance even in wet conditions.

- Customizable Properties: Allows for fine-tuning of performance characteristics to meet specific application requirements.

Comparing Varial Foam to Traditional Foams

When compared to traditional foam materials like open-cell polyurethane, Varial foam offers several distinct advantages. Traditional foams tend to absorb water, degrade more quickly, and offer less consistent performance. Varial foam’s closed-cell structure and engineered properties address these shortcomings, providing a superior alternative in many applications.

For instance, in footwear, traditional foams may compress and lose their cushioning over time, leading to discomfort and reduced performance. Varial foam, on the other hand, maintains its resilience and support, ensuring consistent comfort and performance throughout the lifespan of the shoe. Similarly, in protective gear, traditional foams may not provide adequate impact absorption, increasing the risk of injury. Varial foam’s engineered density and resilience offer superior impact protection, reducing the likelihood of injury.

The Future of Varial Foam Technology

The future of Varial foam technology looks promising, with ongoing research and development focused on further enhancing its properties and expanding its applications. One area of focus is the development of bio-based Varial foam, which would reduce the environmental impact of the material. Another area of focus is the incorporation of advanced materials, such as graphene and carbon nanotubes, to further improve its strength, durability, and conductivity.

As technology advances, we can expect to see Varial foam being used in even more innovative ways. For example, it could be used in smart textiles to create clothing that monitors vital signs and provides customized support. It could also be used in robotics to create robots that are more agile and resilient. The possibilities are endless.

Choosing the Right Varial Foam for Your Needs

Selecting the appropriate Varial foam formulation is crucial to achieving optimal performance. Consider the specific requirements of your application, including the level of cushioning needed, the expected environmental conditions, and the desired lifespan of the product. Consult with a materials expert or manufacturer to determine the best Varial foam for your needs. Factors to consider include density, hardness, compression set, and tensile strength. Additionally, consider any specific certifications or standards that the foam must meet, such as flammability or toxicity requirements. [See also: Foam Material Selection Guide]

Conclusion

Varial foam represents a significant advancement in foam technology, offering superior comfort, enhanced performance, and increased durability compared to traditional foams. Its versatility has led to its adoption across a wide range of industries and applications, from sporting goods to medical devices to industrial products. As research and development continue, we can expect to see even more innovative applications of Varial foam in the future. By understanding the properties and benefits of Varial foam, manufacturers and consumers can make informed decisions and unlock the full potential of this advanced material. The ability to customize the properties of Varial foam makes it a truly versatile material, capable of meeting the diverse needs of a wide range of applications. Whether you are looking for enhanced cushioning, improved energy return, or increased durability, Varial foam offers a solution that can meet your needs.