Understanding Surf Foam: The Building Blocks of Your Ride

For surfers, the ocean is a playground, a sanctuary, and a constant challenge. But before you even paddle out, there’s a crucial element that determines your experience: the surfboard itself. And at the heart of every surfboard lies its core – the surf foam. Understanding the properties and types of surf foam is essential for choosing the right board and maximizing your performance in the water. This article delves into the world of surf foam, exploring its composition, characteristics, and impact on your surfing experience.

What is Surf Foam?

Surf foam, also known as a surfboard blank, is the buoyant material that forms the core of most surfboards. It’s the foundation upon which the surfboard’s shape is created, and it significantly influences the board’s weight, flex, buoyancy, and overall performance. The type of surf foam used can dramatically affect how a board feels and performs in different wave conditions. In essence, it’s the unsung hero of your surfing experience.

Types of Surf Foam

There are several types of surf foam available, each with its own unique properties. The two most common types are polyurethane (PU) and expanded polystyrene (EPS). Let’s break them down:

Polyurethane (PU) Foam

PU foam has been the industry standard for decades. It’s known for its predictable flex patterns, responsiveness, and ease of shaping. Here’s a closer look:

- Characteristics: PU foam is denser and heavier than EPS. It offers a smooth, consistent flex that many surfers prefer. It also absorbs resin well, creating a strong bond with the fiberglass layers.

- Pros: Excellent flex, good responsiveness, easy to shape and repair, widely available.

- Cons: Heavier than EPS, not as environmentally friendly, more susceptible to dings and water absorption if the outer layers are compromised.

- Ideal for: Surfers who prioritize performance and a traditional surfboard feel. It’s also a good choice for boards that need to be strong and durable, especially in heavier surf.

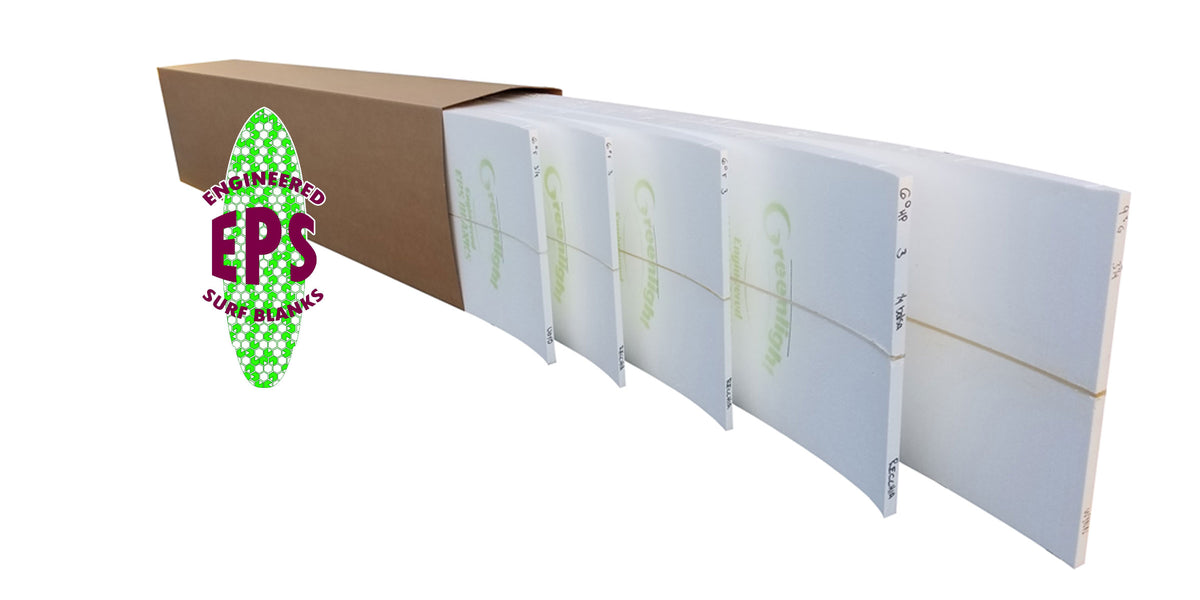

Expanded Polystyrene (EPS) Foam

EPS foam is a lighter and more buoyant alternative to PU. It’s gaining popularity due to its performance characteristics and environmental benefits.

- Characteristics: EPS foam is significantly lighter than PU. It offers increased buoyancy, making it easier to paddle and catch waves. It’s also more resistant to water absorption.

- Pros: Lightweight, very buoyant, more environmentally friendly (recyclable), resistant to water absorption.

- Cons: Can be more difficult to shape, may feel less responsive than PU, requires epoxy resin (more expensive and complex to work with).

- Ideal for: Surfers who want a board that paddles easily and catches waves well, especially in smaller or weaker surf. It’s also a good choice for those looking for a more environmentally friendly option.

Expanded Polypropylene (EPP) Foam

EPP foam is less common in surfboard construction than PU and EPS, but it’s worth mentioning due to its unique properties. It’s known for its high impact resistance and durability.

- Characteristics: EPP foam is very durable and can withstand significant impacts without breaking. It’s also lightweight and buoyant.

- Pros: Highly durable, lightweight, buoyant.

- Cons: Can be more expensive than other types of foam, may not offer the same level of performance as PU or EPS.

- Ideal for: Beginner surfboards, soft-top surfboards, and boards that need to withstand a lot of abuse.

The Impact of Surf Foam on Performance

The type of surf foam used in a surfboard directly impacts its performance. Here’s how:

- Weight: Lighter boards (typically EPS) are easier to paddle and maneuver, especially in smaller waves. Heavier boards (typically PU) can offer more stability and control in larger, more powerful waves.

- Flex: The flex pattern of a surfboard affects how it responds to turns and maneuvers. PU foam generally offers a smoother, more predictable flex, while EPS can feel stiffer.

- Buoyancy: More buoyant boards (EPS) paddle faster and catch waves more easily. This is especially beneficial for beginners and surfers in weaker conditions.

- Responsiveness: The responsiveness of a board refers to how quickly it reacts to your input. PU foam is often considered more responsive than EPS, providing a more direct feel.

Choosing the Right Surf Foam

Selecting the right surf foam depends on several factors, including your skill level, the type of waves you typically surf, and your personal preferences. Here are some considerations:

- Skill Level: Beginners often benefit from the increased buoyancy of EPS boards, which make it easier to paddle and catch waves. More experienced surfers may prefer the responsiveness and control of PU boards.

- Wave Conditions: For small, weak waves, an EPS board can provide the extra paddle power and buoyancy needed to catch waves. For larger, more powerful waves, a PU board can offer more stability and control.

- Personal Preference: Ultimately, the best type of surf foam is the one that feels best to you. Experiment with different types of boards to see what you prefer.

The Shaping Process and Surf Foam

The shaping process is where the raw surf foam transforms into a functional surfboard. Shapers use a variety of tools, including planers, sanders, and templates, to create the desired shape. The ease with which a surf foam can be shaped is a crucial factor for shapers.

PU foam is generally considered easier to shape than EPS, allowing for more intricate designs and refined rails. EPS foam, while more challenging, can still be shaped with precision using specialized tools and techniques. The final shape of the board, combined with the properties of the surf foam, determines its overall performance characteristics.

Environmental Considerations and Surf Foam

The environmental impact of surfboard manufacturing is a growing concern. Traditional PU foam is not biodegradable and releases harmful chemicals during production. EPS foam is often considered a more environmentally friendly alternative because it can be recycled. However, the epoxy resins used with EPS also have environmental impacts.

Many surfboard manufacturers are exploring more sustainable materials and processes, including bio-based resins and recycled surf foam. As the surfing industry becomes more aware of its environmental footprint, expect to see continued innovation in surf foam technology.

The Future of Surf Foam

The future of surf foam is likely to be driven by a combination of performance and sustainability. Expect to see continued development of new materials and technologies that offer improved performance while minimizing environmental impact. This could include bio-based foams, recycled foams, and innovative shaping techniques that reduce waste.

The demand for high-performance surfboards will continue to drive innovation in surf foam technology. Surfers are constantly seeking boards that allow them to push their limits and perform at their best. As a result, manufacturers will continue to invest in research and development to create surf foam that meets the evolving needs of surfers.

Repairing Surf Foam Damage

Regardless of the type of surf foam your board is made from, damage can occur. Dings, cracks, and delamination are common issues that can affect performance and longevity. Prompt repair is essential to prevent water absorption and further damage.

PU foam is generally easier to repair than EPS. Repair kits are readily available, and the process is relatively straightforward. EPS repairs require epoxy resin, which can be more complex to work with. It’s always best to consult with a qualified surfboard repair technician for significant damage.

Conclusion: Surf Foam – The Core of Your Surfing Experience

Understanding surf foam is crucial for making informed decisions about your surfboard. Whether you prefer the traditional feel of PU or the lightweight buoyancy of EPS, the type of surf foam you choose will significantly impact your surfing experience. By considering your skill level, the wave conditions you typically surf, and your personal preferences, you can select a board that maximizes your performance and enjoyment in the water. As the surfing industry continues to evolve, expect to see even more innovation in surf foam technology, leading to boards that are both high-performing and environmentally sustainable. So next time you’re waxing up your board, take a moment to appreciate the surf foam beneath your feet – it’s the foundation of your ride. [See also: Surfboard Design Principles] [See also: How to Choose the Right Surfboard] [See also: Surfboard Repair Techniques]