Understanding Surf Foam: The Building Blocks of a Great Ride

Surf foam is more than just the white stuff you see when waves break. It’s the very foundation of your surfboard, influencing everything from buoyancy and responsiveness to durability and overall performance. Choosing the right surf foam is crucial for maximizing your time in the water, whether you’re a seasoned pro or just starting to paddle out. This article delves into the different types of surf foam, their characteristics, and how they impact your surfing experience.

What is Surf Foam?

Surf foam, in its simplest form, is a lightweight, closed-cell material used in the core of most surfboards. It provides the surfboard with its shape, buoyancy, and structural integrity. The type of surf foam used significantly affects how the board performs in different wave conditions and under varying rider weights and skill levels. Understanding the nuances of different surf foam types empowers surfers to make informed decisions when selecting a board.

Types of Surf Foam

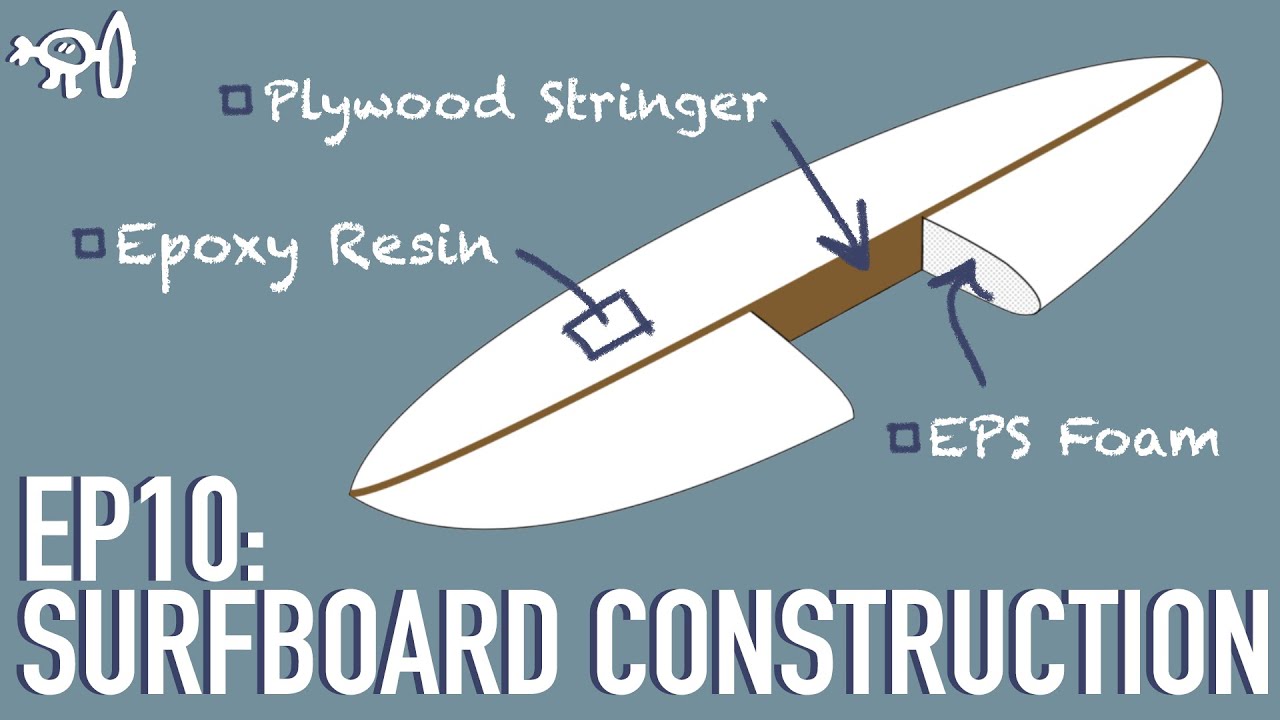

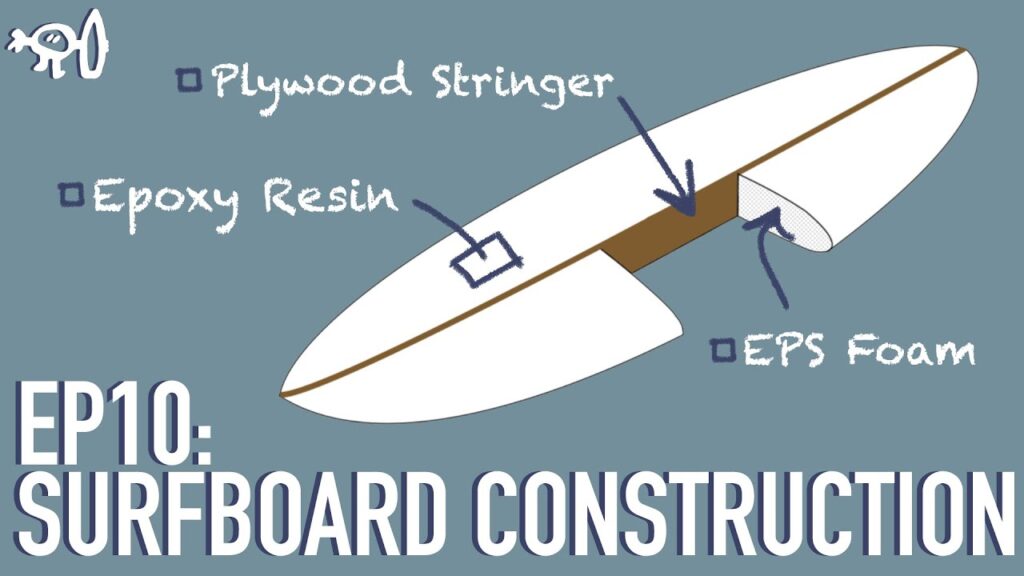

There are primarily two types of surf foam used in surfboard construction: polyurethane (PU) and expanded polystyrene (EPS). Each has its own set of advantages and disadvantages.

Polyurethane (PU) Foam

PU foam has been the industry standard for decades. It’s known for its flexibility, responsiveness, and ease of shaping. PU foam boards typically offer a smooth, controlled ride, making them a favorite among surfers of all levels. The density of the PU foam can be adjusted to fine-tune the board’s flex characteristics.

- Advantages: Excellent flex, responsive feel, easy to shape and repair, readily available.

- Disadvantages: More prone to water absorption if dinged, heavier than EPS foam, uses petrochemicals in its production.

Expanded Polystyrene (EPS) Foam

EPS foam is a lighter alternative to PU. It’s characterized by its distinct bead-like structure. EPS boards are known for their buoyancy and speed, making them ideal for smaller waves and surfers looking for extra floatation. EPS foam is often used in conjunction with epoxy resin, resulting in a lighter and stronger board compared to traditional PU/polyester constructions. Many believe that surf foam made of EPS offers better performance in weaker wave conditions.

- Advantages: Lightweight, high buoyancy, strong when paired with epoxy resin, more environmentally friendly than PU.

- Disadvantages: Can be more difficult to shape, less flexible than PU, more susceptible to pressure dings.

Other Types of Surf Foam

While PU and EPS are the most common, other types of surf foam are emerging in the market. These include:

- Expanded Polypropylene (EPP): Known for its durability and impact resistance, often used in soft-top surfboards.

- Bio-Foam: Made from renewable resources, offering a more sustainable alternative to traditional foam.

Factors to Consider When Choosing Surf Foam

Selecting the right surf foam depends on several factors, including your skill level, the type of waves you typically surf, and your personal preferences.

Skill Level

Beginner surfers often benefit from the added buoyancy of EPS foam, which makes it easier to paddle and catch waves. More experienced surfers may prefer the responsiveness and control of PU foam, allowing them to perform more advanced maneuvers. The type of surf foam can significantly impact the learning curve for new surfers.

Wave Conditions

EPS boards generally perform better in smaller, weaker waves due to their increased buoyancy and speed. PU boards excel in larger, more powerful waves, offering greater control and stability. Consider the typical wave conditions you surf when choosing your surf foam.

Board Design

The overall design of the surfboard also plays a crucial role. A high-performance shortboard might benefit from the responsiveness of PU foam, while a longboard might thrive with the buoyancy of EPS. The shape and dimensions of the board should complement the characteristics of the surf foam.

Environmental Considerations

Traditional surf foam production can have a significant environmental impact. Consider choosing boards made with recycled foam or bio-foam to minimize your carbon footprint. Look for manufacturers who are committed to sustainable practices. The environmental impact of surf foam is becoming increasingly important to conscious consumers.

The Impact of Surf Foam on Board Performance

The type of surf foam directly influences several key aspects of board performance:

Buoyancy

EPS foam is significantly more buoyant than PU foam, making it easier to paddle and catch waves, especially in weaker conditions. This increased buoyancy also allows for thinner board designs, further enhancing speed and responsiveness. The relationship between surf foam and buoyancy is critical for wave catching.

Flex

PU foam offers a more natural flex pattern compared to EPS. This flex allows the board to conform to the wave’s surface, providing a smoother and more controlled ride. The flex characteristics of surf foam affect how the board feels under your feet.

Responsiveness

The responsiveness of a surfboard refers to how quickly it reacts to your input. PU foam generally provides a more direct and responsive feel, allowing for quicker turns and more precise maneuvers. Responsive surf foam is essential for high-performance surfing.

Durability

While both PU and EPS boards can be durable, EPS boards are generally more resistant to dings and pressure dents when constructed with epoxy resin. However, PU boards are typically easier to repair. The durability of surf foam impacts the lifespan of your surfboard.

Surf Foam and the Future of Surfing

The surf industry is constantly evolving, with new technologies and materials emerging all the time. Surf foam is no exception. Research and development are focused on creating more sustainable and high-performance foam options. As surfers become more environmentally conscious, the demand for eco-friendly surf foam alternatives will continue to grow. Innovations in surf foam technology are shaping the future of surfing.

Caring for Your Surf Foam Board

Regardless of the type of surf foam your board is made from, proper care and maintenance are essential for prolonging its lifespan. Here are a few tips:

- Rinse your board with fresh water after each surf session. This removes salt and sand, which can damage the foam over time.

- Store your board in a cool, dry place away from direct sunlight. Excessive heat and UV exposure can cause the foam to degrade.

- Repair any dings or cracks immediately. Water absorption can lead to delamination and further damage to the foam core.

- Use a board bag to protect your board during transport. This will prevent dings and scratches.

Conclusion

Understanding surf foam is essential for choosing the right surfboard and maximizing your surfing experience. By considering factors such as skill level, wave conditions, and personal preferences, you can select a board that complements your style and enhances your performance. Whether you opt for the classic feel of PU or the lightweight buoyancy of EPS, the right surf foam can make all the difference in your ride. As the industry continues to innovate, we can expect even more advanced and sustainable surf foam options to emerge, further revolutionizing the sport of surfing. Choosing the right surf foam will improve your ride every time. The type of surf foam is a key consideration for any surfer. Surf foam technology is constantly improving. Consider the type of surf foam when purchasing your next board. Surf foam affects the overall performance of the board. Different types of surf foam suit different surfing styles. Surf foam is the backbone of your surfboard. Surf foam selection depends on wave conditions. Understanding surf foam helps you choose the right board. Surf foam innovation is driving the future of surfing.

[See also: Choosing the Right Surfboard for Beginners]

[See also: Understanding Surfboard Fins]

[See also: Surfboard Repair Basics]