Surfboard Clay: The Unsung Hero of Performance and Design

In the world of surfing, where every wave presents a unique challenge and every surfer seeks the perfect ride, the tools of the trade are constantly evolving. While much attention is given to the shape, size, and materials of the surfboard itself, a less-celebrated yet crucial component plays a significant role: surfboard clay. This seemingly simple material is instrumental in both the design and repair processes, acting as a sculptor’s medium and a restorer’s aid. Understanding the properties, uses, and significance of surfboard clay is essential for anyone serious about surfing, from beginners to seasoned professionals.

What Exactly is Surfboard Clay?

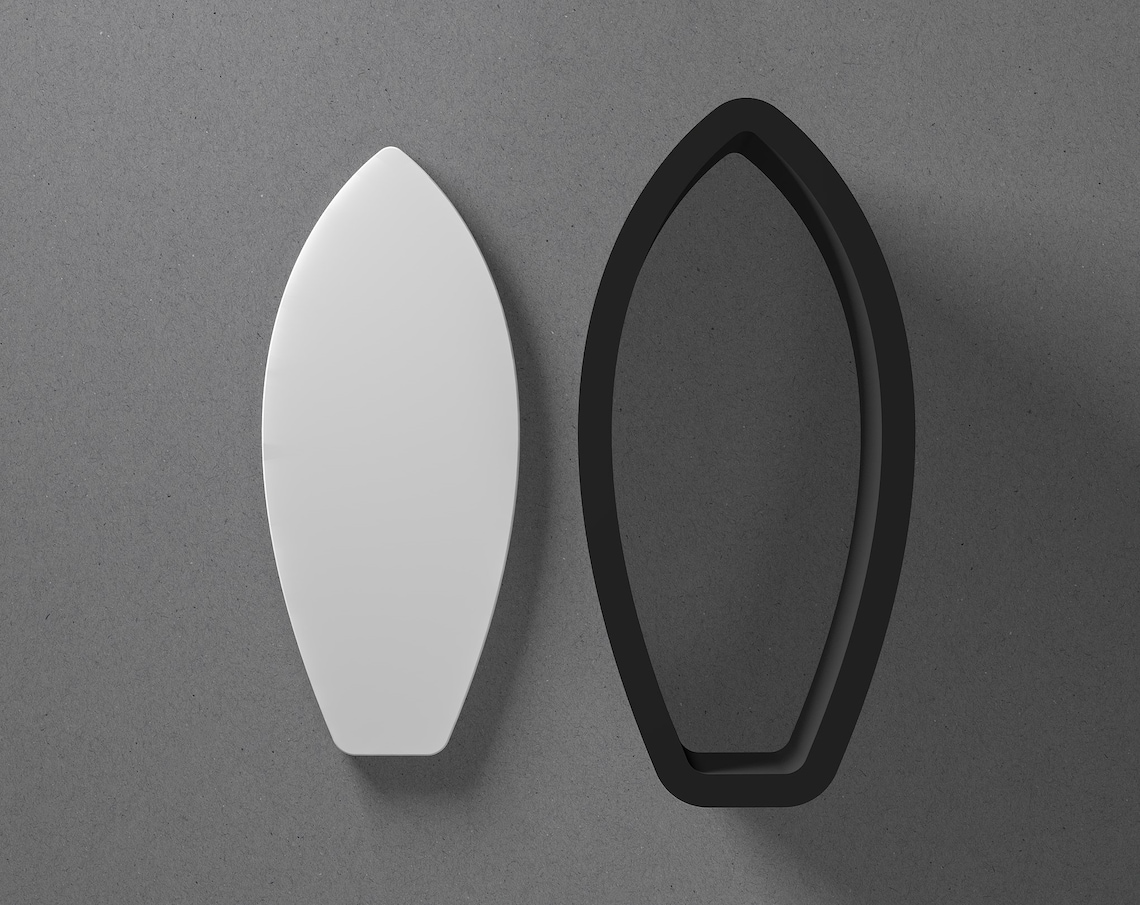

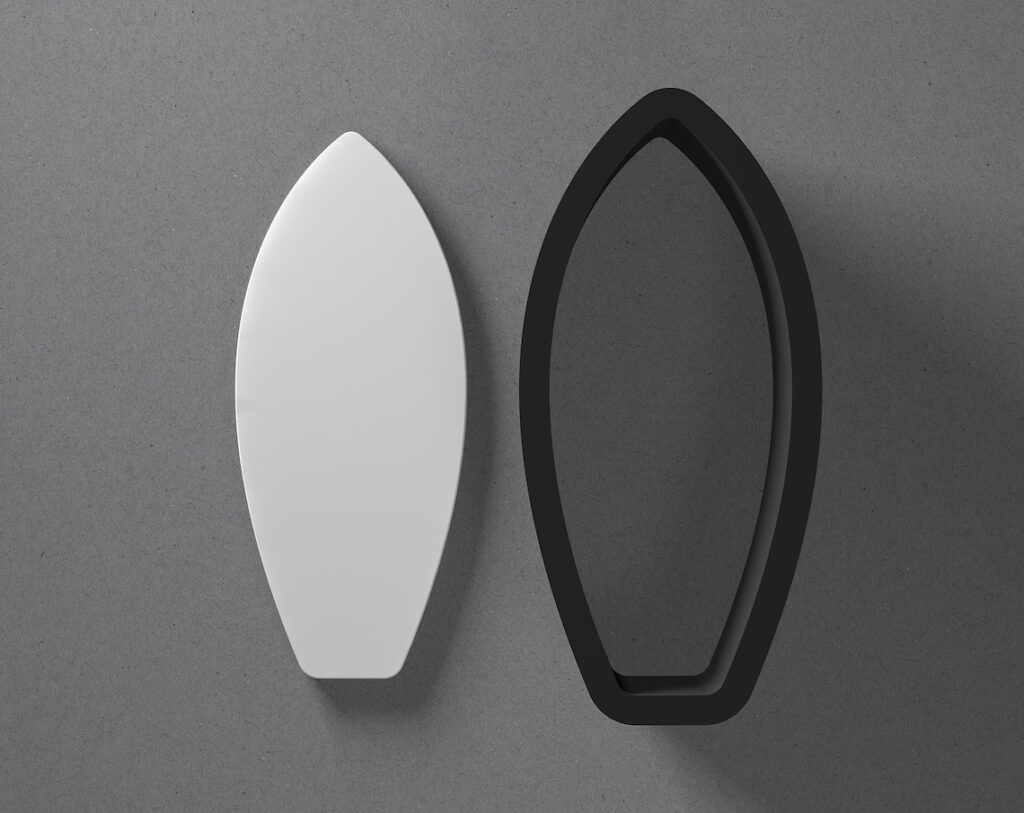

Surfboard clay, also known as shaping clay or modeling clay, is a malleable substance used primarily by surfboard shapers and repair technicians. Unlike traditional pottery clay, surfboard clay is typically oil-based or polymer-based, meaning it doesn’t dry out or harden in the same way. This allows for repeated use and adjustments, making it ideal for the iterative processes involved in surfboard creation and repair. The primary goal of utilizing surfboard clay is to create a smooth, even surface for the surfboard’s finish.

Composition and Properties

The composition of surfboard clay varies depending on the manufacturer and intended use. Oil-based clays are often made from a mixture of mineral oils, waxes, and fillers. Polymer-based clays, on the other hand, contain polymers that provide flexibility and durability. Both types share several key properties:

- Malleability: The clay must be easily shaped and molded to conform to the contours of the surfboard.

- Non-Hardening: It should remain pliable over extended periods, allowing for multiple adjustments.

- Non-Shrinking: The clay shouldn’t shrink or crack as it sits, ensuring accurate shaping and repairs.

- Adhesion: It needs to adhere well to the surfboard’s foam core without damaging it.

- Easy Removal: Once the shaping or repair is complete, the clay should be easily removable without leaving residue.

The Role of Surfboard Clay in Surfboard Design

The creation of a surfboard is a meticulous process that blends art and science. Surfboard clay plays a vital role in refining the shape and ensuring the board meets the shaper’s exact specifications. Here’s how it’s used:

Shaping and Contouring

During the shaping process, the shaper uses various tools to carve the surfboard blank into the desired form. Surfboard clay is then applied to specific areas to smooth out imperfections, refine curves, and create precise contours. This is particularly important for critical areas like the rails (the edges of the board) and the bottom contours, which significantly affect the board’s performance in the water. By adding and subtracting small amounts of clay, shapers can fine-tune the board’s hydrodynamics and optimize its responsiveness.

Creating Templates and Molds

Surfboard clay is also used to create templates and molds for replicating specific surfboard designs. A shaper can sculpt a master template using clay, then use that template to guide the shaping of future boards. This ensures consistency and accuracy, especially when producing multiple boards of the same model. In some cases, clay molds are created for more complex shapes or features, allowing for mass production while maintaining quality control. [See also: Surfboard Shaping Techniques]

Experimentation and Innovation

The malleable nature of surfboard clay makes it an ideal medium for experimentation. Shapers can use it to test new design ideas, prototype different fin placements, or explore unconventional bottom contours without committing to permanent changes. This allows for a more iterative and creative design process, leading to innovations in surfboard technology. The shaper can quickly add to or remove material to test the hydrodynamic effects of the changes.

Surfboard Clay in Repair and Maintenance

Beyond its role in surfboard design, surfboard clay is also an essential tool for repairing damaged boards. Dings, cracks, and delaminations are common occurrences in surfing, and surfboard clay helps to restore the board’s integrity and performance.

Filling Dings and Cracks

When a surfboard sustains a ding or crack, water can seep into the foam core, causing further damage. Surfboard clay is used to temporarily fill these imperfections, preventing water intrusion and stabilizing the damaged area. This is especially crucial for minor dings that might otherwise be overlooked. By filling the ding with clay, the surfer can continue using the board until a more permanent repair can be made. This prevents the core from becoming waterlogged.

Creating a Smooth Surface for Repairs

Before applying resin or fiberglass to repair a damaged area, it’s essential to create a smooth, even surface. Surfboard clay is used to fill in gaps, smooth out rough edges, and blend the repair area seamlessly with the surrounding surface. This ensures a strong and aesthetically pleasing repair. The clay acts as a temporary filler, allowing the repair technician to shape the area before applying permanent materials.

Protecting Sensitive Areas

During the repair process, certain areas of the surfboard may need to be protected from accidental damage or resin spills. Surfboard clay can be used to mask off these areas, providing a barrier that prevents unwanted damage. This is particularly useful when working on delicate areas like fin boxes or leash plugs. The clay can be easily removed after the repair is complete, leaving a clean and professional finish.

Choosing the Right Surfboard Clay

With various types of surfboard clay available on the market, selecting the right one for your needs is essential. Consider the following factors:

Oil-Based vs. Polymer-Based

Oil-based clays are generally more affordable and readily available. They offer good malleability and adhesion, making them suitable for most shaping and repair tasks. However, they can be slightly messier and may require more effort to remove. Polymer-based clays, on the other hand, are more durable and resistant to drying out. They also tend to be easier to clean up, but they may be more expensive. The choice depends on personal preference and the specific requirements of the task.

Consistency and Texture

The consistency and texture of the clay should be appropriate for the intended use. Softer clays are easier to mold and shape, while firmer clays hold their shape better and are less prone to smearing. Consider the size and complexity of the area you’re working on when choosing the right consistency. A softer clay is ideal for filling small dings or creating intricate contours, while a firmer clay is better for larger repairs or creating templates.

Brand and Quality

Opt for reputable brands known for producing high-quality surfboard clay. Read reviews and compare different products to find one that meets your specific needs and budget. Investing in a good-quality clay will ensure better results and prevent frustration during the shaping or repair process. Some brands offer clays specifically formulated for surfboard applications, which may offer superior performance and durability.

Tips for Using Surfboard Clay Effectively

To get the most out of your surfboard clay, follow these tips:

- Keep it Clean: Store the clay in an airtight container to prevent it from drying out or becoming contaminated with dirt or debris.

- Warm it Up: If the clay is too firm, warm it up slightly by kneading it in your hands or placing it in a warm environment.

- Use the Right Tools: Employ shaping tools, spatulas, or even your fingers to mold and shape the clay effectively.

- Apply Sparingly: Use only the amount of clay needed to achieve the desired result. Over-application can make it difficult to remove and may affect the repair’s integrity.

- Remove Carefully: When removing the clay, use a clean cloth or scraper to avoid damaging the surfboard’s surface.

The Future of Surfboard Clay

As surfboard technology continues to advance, so too will the materials and techniques used in their creation and repair. While surfboard clay may seem like a simple tool, its importance in the world of surfing remains undeniable. Ongoing research and development are likely to lead to even more advanced and versatile clays, further enhancing the performance and durability of surfboards. [See also: Advanced Surfboard Materials]

The future may see the development of clays with enhanced adhesion, improved water resistance, or even self-healing properties. Nanotechnology could also play a role, with nanoparticles being incorporated into the clay to enhance its strength and flexibility. Regardless of the specific advancements, surfboard clay will undoubtedly remain a vital component of the surfing experience for years to come. The constant innovation in surfboard design demands equally innovative materials to support the creative process.

Conclusion

Surfboard clay is an indispensable material in the surfboard industry, playing a crucial role in both the design and repair of these essential wave-riding vehicles. Its malleability, non-hardening properties, and ease of use make it an ideal medium for shaping, contouring, filling imperfections, and protecting sensitive areas. Whether you’re a seasoned shaper, a dedicated repair technician, or simply a surfer who wants to keep their board in top condition, understanding the importance of surfboard clay is essential. So, the next time you admire a perfectly shaped surfboard or marvel at a seamlessly repaired ding, remember the unsung hero behind it all: surfboard clay. Its contribution to the art and science of surfing is undeniable, and its continued evolution promises to shape the future of the sport. The meticulous use of surfboard clay contributes directly to the surfer’s experience in the water.