Surfboard Clay: The Unsung Hero of Performance and Customization

In the world of surfing, where every wave is a unique canvas and every ride a personal expression, the tools of the trade are constantly evolving. While high-tech materials and hydrodynamic designs often steal the spotlight, a humble yet indispensable substance plays a crucial role in refining the performance and customization of surfboards: surfboard clay. This article delves into the multifaceted applications of surfboard clay, exploring its composition, benefits, and the techniques employed by shapers and surfers alike.

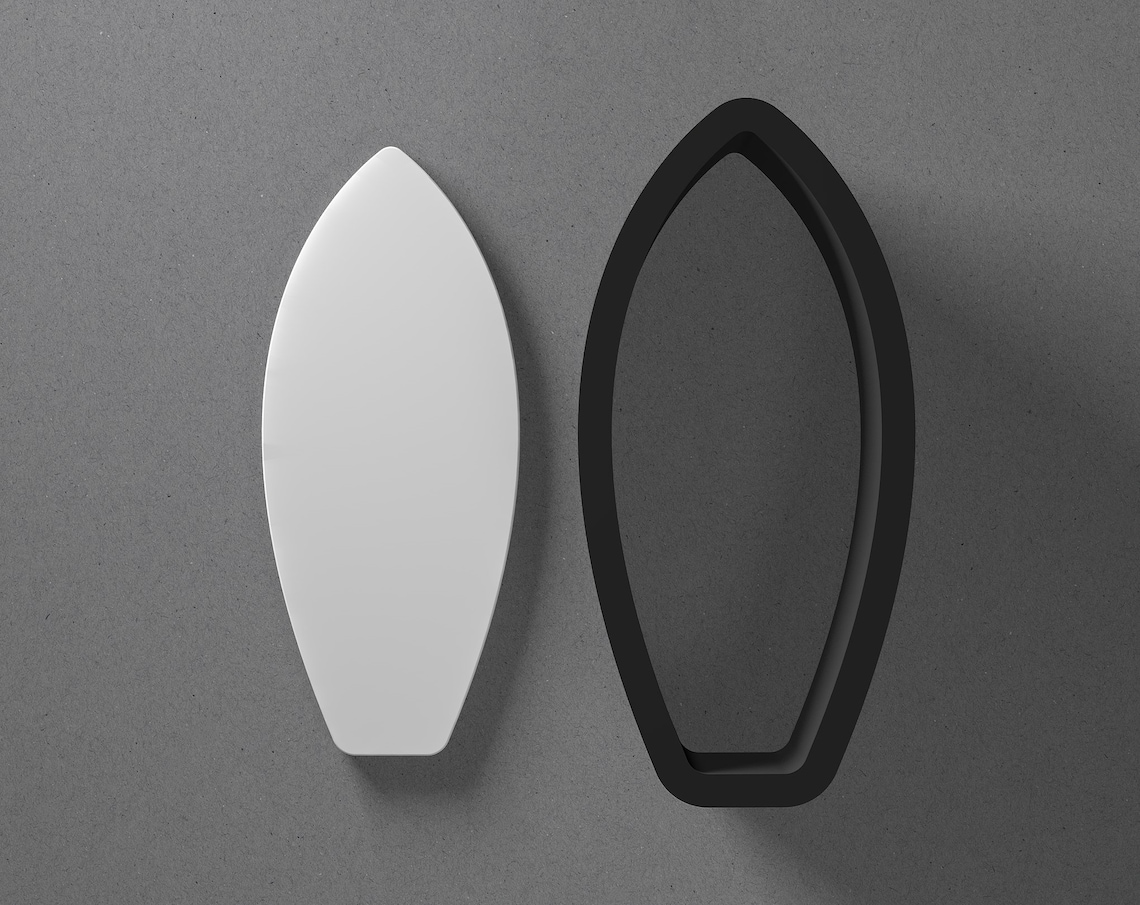

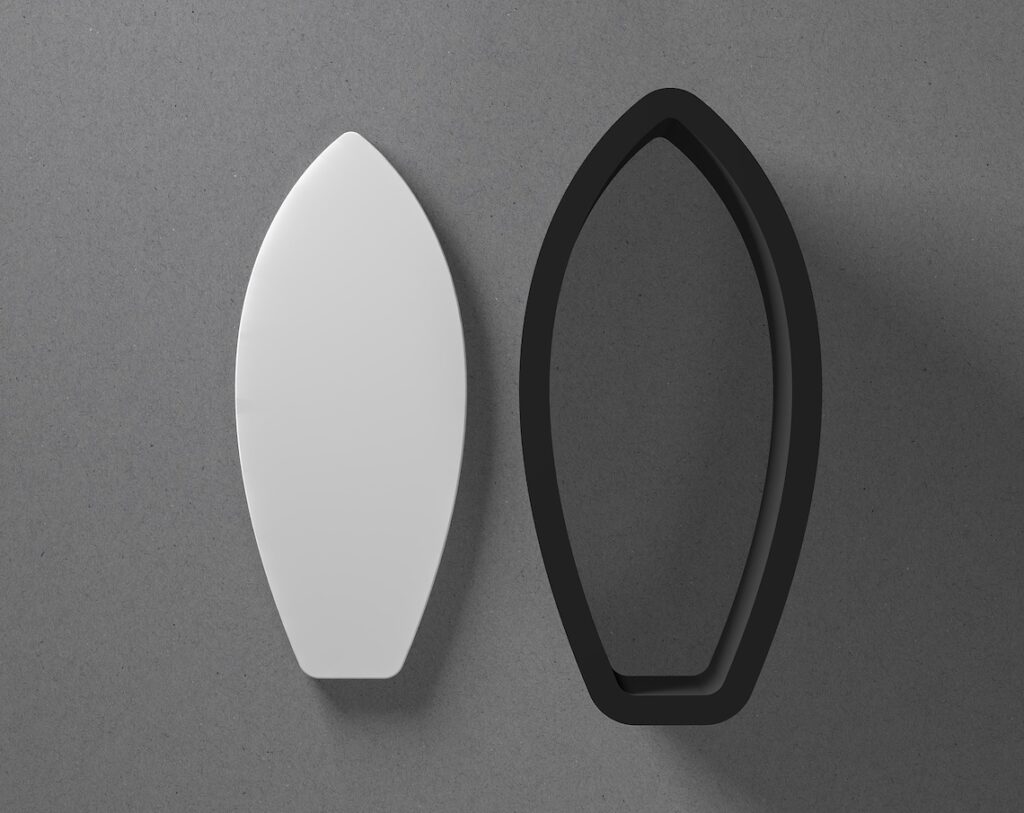

What is Surfboard Clay?

Surfboard clay, also known as modeling clay or shaping clay, is a pliable, non-hardening material used primarily for fine-tuning the contours and features of surfboards. Unlike resin or foam, surfboard clay doesn’t become a permanent part of the board. Instead, it serves as a temporary medium for experimentation and refinement. The most common types are oil-based clays, prized for their workability and resistance to drying out. Some water-based clays also see use, but require careful handling to prevent warping the underlying foam.

The Role of Surfboard Clay in Shaping

For surfboard shapers, surfboard clay is an invaluable tool in the design process. It allows them to visualize and test different design elements before committing to permanent changes. Here’s how it’s used:

Refining Rail Shape

The rails of a surfboard – the edges along the sides – significantly impact how the board interacts with the water. Surfboard clay can be applied to the rails to experiment with different thicknesses, contours, and hardness. Shapers can add or remove clay to achieve the desired feel and performance characteristics. This iterative process allows for precise adjustments that can dramatically alter the board’s responsiveness and control.

Adjusting Rocker Profiles

Rocker refers to the curvature of the surfboard from nose to tail. Even slight changes in rocker can affect a board’s paddling speed, wave entry, and turning ability. Shapers use surfboard clay to temporarily modify the rocker profile, testing different curves to optimize the board for specific wave conditions or riding styles. This is particularly useful for fine-tuning prototypes or adapting existing boards to new environments.

Experimenting with Concaves and Channels

Concaves and channels are subtle contours on the bottom of the surfboard that influence water flow and lift. Surfboard clay allows shapers to experiment with different concave depths, shapes, and placements. By adding or subtracting clay, they can observe how these modifications affect the board’s speed, acceleration, and maneuverability. This iterative process helps them to dial in the optimal bottom contour for a given design.

Surfboard Clay for Surfers: Customization and Repair

While primarily used by shapers, surfboard clay also offers benefits for surfers looking to customize or repair their boards. Here are some common applications:

Fine-Tuning Grip and Feel

Some surfers use surfboard clay to subtly alter the shape of their deck, improving grip and comfort. For example, adding a small amount of clay under the traction pad can create a more secure and responsive feel. Similarly, clay can be used to fill in minor depressions or imperfections on the deck, providing a smoother and more consistent surface.

Temporary Repairs and Adjustments

In a pinch, surfboard clay can serve as a temporary fix for minor dings or cracks. While it’s not a substitute for proper resin repair, clay can help to seal the damaged area and prevent water from seeping into the foam core. This can be particularly useful during surf trips or when immediate repairs are not possible. It’s important to note that this is a temporary solution, and the board should be professionally repaired as soon as possible. [See also: Surfboard Repair Techniques]

Weight Distribution Adjustments

Advanced surfers sometimes use surfboard clay to experiment with weight distribution. By strategically placing small amounts of clay on the deck, they can subtly alter the board’s balance and responsiveness. This technique is often used to fine-tune boards for specific wave types or riding styles. However, it requires a deep understanding of surfboard dynamics and should be approached with caution.

Types of Surfboard Clay

Choosing the right type of surfboard clay is essential for achieving the desired results. Here are some of the most common options:

- Oil-Based Clay: This is the most popular type of surfboard clay due to its excellent workability and resistance to drying out. Oil-based clays are pliable, easy to shape, and can be repeatedly molded and reused. They are also relatively resistant to temperature changes, making them suitable for use in a variety of environments.

- Water-Based Clay: Water-based clays are less common for surfboard shaping due to their tendency to shrink and crack as they dry. However, they can be useful for certain applications, such as creating textured surfaces or adding fine details. Water-based clays require careful handling to prevent warping or damaging the underlying foam.

- Polymer Clay: While not technically a traditional clay, polymer clay is sometimes used for creating small, durable modifications to surfboards. Polymer clay is a synthetic material that hardens when baked, making it suitable for adding permanent features or reinforcing weak areas. However, it’s important to choose a polymer clay that is compatible with the surfboard’s materials and to follow the manufacturer’s instructions carefully.

Tips for Using Surfboard Clay

To get the most out of surfboard clay, consider these tips:

- Keep it Clean: Always work with clean clay and a clean surfboard surface. Dirt and debris can contaminate the clay and affect its adhesion.

- Warm it Up: Warming the clay slightly before use can make it more pliable and easier to shape. You can warm it with your hands or by placing it in a warm room.

- Apply in Thin Layers: Apply the clay in thin, even layers to avoid creating lumps or uneven surfaces.

- Smooth it Out: Use a shaping tool or your fingers to smooth out the clay and blend it seamlessly with the surrounding surface.

- Experiment and Iterate: Don’t be afraid to experiment with different shapes and contours. The beauty of surfboard clay is that it’s temporary, so you can always start over if you’re not happy with the results.

- Remove Carefully: When you’re finished, carefully remove the clay from the surfboard. Use a clean cloth or scraper to avoid scratching the surface.

The Future of Surfboard Clay

While digital design tools and advanced manufacturing techniques are becoming increasingly prevalent in the surfboard industry, surfboard clay remains a valuable and versatile tool. Its tactile nature and ability to facilitate hands-on experimentation make it an indispensable part of the shaping process. As shapers continue to push the boundaries of surfboard design, surfboard clay will undoubtedly play a vital role in bringing their visions to life. Furthermore, the accessibility of surfboard clay empowers surfers to engage in minor customization and repairs, fostering a deeper connection with their boards and the surfing experience. [See also: Sustainable Surfboard Materials]

In conclusion, surfboard clay is more than just a modeling material; it’s a key ingredient in the pursuit of optimal performance and personalized riding experiences. Whether you’re a seasoned shaper or a passionate surfer, understanding the benefits and applications of surfboard clay can unlock new levels of creativity and innovation in the world of surfing. The ability to manipulate and refine the shape and feel of a surfboard, even in small increments, allows for a level of customization that is unmatched by mass-produced boards. So, the next time you see a surfer carving effortlessly across a wave, remember the unsung hero behind the scenes: surfboard clay.