Poly Surf Board: A Comprehensive Guide to Performance, Durability, and Value

The world of surfing is constantly evolving, with new materials and construction techniques emerging regularly. Among the various surfboard options available, the poly surf board stands out as a popular choice for surfers of all levels. This comprehensive guide delves into the intricacies of poly surf boards, exploring their construction, performance characteristics, advantages, disadvantages, and how they compare to other surfboard types. Whether you’re a seasoned wave rider or just starting out, understanding the nuances of poly surf boards will help you make an informed decision when choosing your next board.

What is a Poly Surf Board?

A poly surf board, short for polyurethane surfboard, is a type of surfboard constructed using a polyurethane (PU) foam core. This core is then wrapped in layers of fiberglass cloth and saturated with polyester resin. The combination of these materials creates a board that is both buoyant and strong. Polyurethane has been a staple in surfboard construction for decades, prized for its responsiveness and relatively affordable cost.

The Construction Process

The creation of a poly surf board involves a multi-step process:

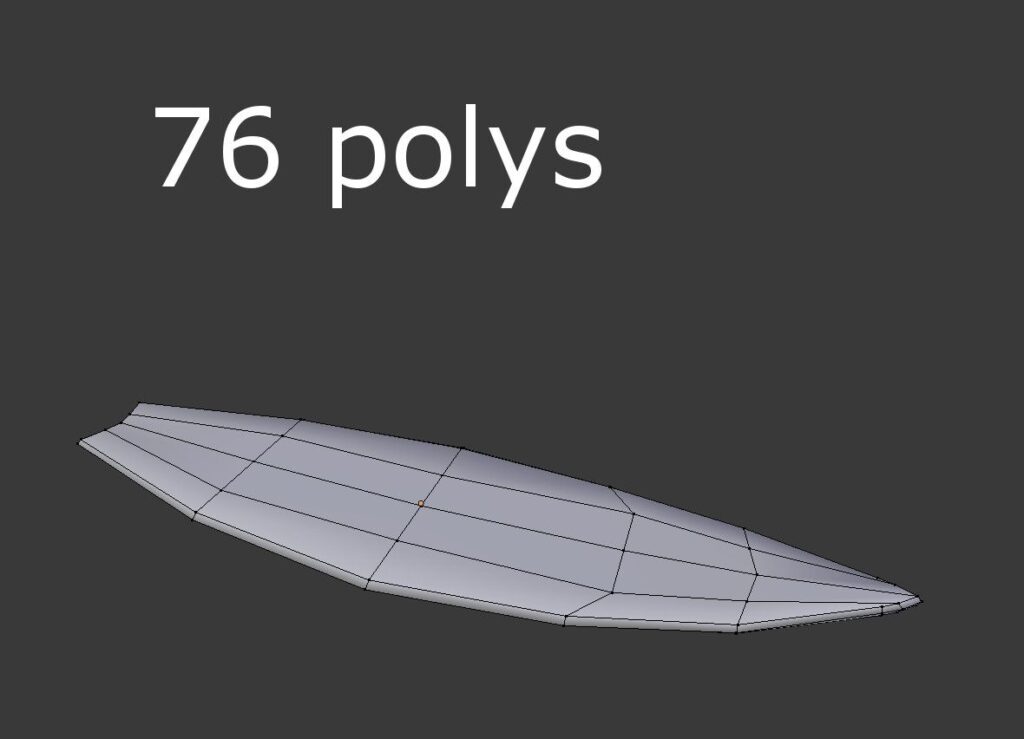

- Shaping the Core: A block of polyurethane foam is carefully shaped by a surfboard shaper, either by hand or using computer-aided design (CAD) and CNC milling machines, to achieve the desired board outline, rocker, and foil.

- Glassing: Layers of fiberglass cloth are applied to the shaped foam core. The number of layers and the weight of the fiberglass cloth can be varied to adjust the board’s strength and flex characteristics.

- Resin Application: Polyester resin is applied to saturate the fiberglass cloth, bonding it to the foam core and creating a hard, protective shell.

- Sanding and Finishing: Once the resin has cured, the board is sanded to create a smooth surface. A final gloss coat is often applied for added protection and aesthetic appeal.

Performance Characteristics of Poly Surf Boards

Poly surf boards are known for their distinct performance characteristics, which make them suitable for a wide range of surfing conditions and rider preferences.

Responsiveness and Flex

One of the key advantages of poly surf boards is their responsiveness. The polyurethane foam core offers a good balance of stiffness and flex, allowing the board to react quickly to rider input. This responsiveness translates to better control and maneuverability, particularly in critical sections of the wave.

Drive and Projection

The combination of the PU core and fiberglass/polyester resin lamination provides poly surf boards with excellent drive and projection. When you push down on the board, it stores energy and then releases it, propelling you forward and allowing you to maintain speed through turns.

Versatility

Poly surf boards are versatile and can be shaped into a variety of designs to suit different wave types and surfing styles. From shortboards designed for high-performance surfing to longboards ideal for cruising, poly surf boards can be adapted to meet the needs of almost any surfer. [See also: Surfboard Types for Beginners]

Advantages of Poly Surf Boards

Choosing a poly surf board offers several benefits:

- Performance: Renowned for their responsiveness and drive, making them ideal for experienced surfers and those looking to improve their skills.

- Cost-Effectiveness: Generally more affordable than epoxy surfboards, making them accessible to a wider range of surfers.

- Repairability: Polyester resin is relatively easy to work with, making poly surf boards easier and more cost-effective to repair compared to epoxy boards.

- Flexibility in Shaping: PU foam is easy to shape, allowing shapers to create a wide variety of designs.

Disadvantages of Poly Surf Boards

While poly surf boards offer many advantages, they also have some drawbacks:

- Durability: More susceptible to dings and pressure dents compared to epoxy surfboards.

- Weight: Generally heavier than epoxy boards, which can affect their performance in certain conditions.

- Environmental Impact: The materials used in the construction of poly surf boards are not as environmentally friendly as some alternative materials.

Poly Surf Board vs. Epoxy Surf Board

The most common alternative to poly surf boards is epoxy surfboards. Here’s a comparison of the two:

Materials and Construction

Epoxy surfboards use an epoxy resin instead of polyester resin and often incorporate different types of foam cores, such as EPS (expanded polystyrene). This construction method results in a lighter and stronger board.

Performance

Epoxy surfboards are generally faster and more buoyant than poly surf boards. They tend to float higher in the water and generate more speed. However, some surfers find them to be less responsive and less forgiving than poly surf boards. [See also: Epoxy Surfboard Repair Guide]

Durability

Epoxy surfboards are significantly more durable than poly surf boards. They are less prone to dings and pressure dents and can withstand more abuse.

Cost

Epoxy surfboards are typically more expensive than poly surf boards due to the higher cost of materials and the more complex construction process.

Choosing the Right Poly Surf Board

Selecting the right poly surf board depends on several factors:

Skill Level

Beginners may benefit from a larger, more stable poly surf board that is easy to paddle and catch waves on. Intermediate and advanced surfers can choose more performance-oriented designs that suit their specific riding style.

Wave Conditions

Consider the type of waves you typically surf. For small, mushy waves, a wider, flatter poly surf board with plenty of volume will help you generate speed. For steeper, more powerful waves, a narrower board with more rocker will provide better control.

Board Dimensions

Pay attention to the board’s length, width, and thickness. These dimensions will affect the board’s buoyancy, stability, and maneuverability. Consult with a surfboard shaper or experienced surfer to determine the optimal dimensions for your size and skill level.

Maintaining Your Poly Surf Board

Proper care and maintenance will extend the life of your poly surf board:

- Rinse after each use: Wash your board with fresh water to remove salt, sand, and other debris.

- Store properly: Keep your board out of direct sunlight and extreme temperatures. Store it in a board bag or rack to protect it from damage.

- Repair dings promptly: Even small dings can allow water to penetrate the foam core, causing delamination and other problems. Repair any damage as soon as possible.

The Future of Poly Surf Boards

While epoxy surfboards have gained popularity in recent years, poly surf boards remain a viable and popular option for surfers of all levels. Ongoing advancements in materials and construction techniques are helping to improve the durability and performance of poly surf boards, ensuring their continued relevance in the surfing world. The classic feel and responsiveness of a well-shaped poly surf board are hard to replicate, and many surfers still prefer the traditional feel of polyurethane under their feet.

Conclusion

The poly surf board is a time-tested design that offers a unique blend of performance, affordability, and repairability. While they may not be as durable as epoxy boards, their responsiveness and feel make them a favorite among many surfers. By understanding the characteristics of poly surf boards and considering your own surfing style and preferences, you can choose the perfect board to enhance your wave-riding experience. Whether you are carving down the line or just learning to stand, a poly surf board can be a great tool to improve and enjoy your time in the water.