Kevlar Used: Unveiling the Applications of This Super Strong Material

Kevlar, a name synonymous with strength and resilience, is a para-aramid synthetic fiber known for its exceptional tensile strength-to-weight ratio. Developed by Stephanie Kwolek at DuPont in 1965, it has since revolutionized various industries, offering solutions where lightweight, high-strength materials are crucial. This article delves into the diverse applications of Kevlar used across different sectors, exploring its unique properties and the reasons behind its widespread adoption.

The Science Behind Kevlar’s Strength

Understanding the applications of Kevlar used requires a grasp of its unique molecular structure. Kevlar’s strength stems from its tightly packed, highly oriented molecules. These molecules are linked by strong hydrogen bonds, creating a rigid, crystalline structure. This structure allows Kevlar to absorb and dissipate energy efficiently, making it resistant to impact and penetration. The result is a material five times stronger than steel on an equal-weight basis.

Furthermore, Kevlar exhibits excellent resistance to heat, chemicals, and abrasion. It doesn’t melt, although it will degrade at high temperatures. Its chemical inertness makes it suitable for use in harsh environments. This combination of properties makes Kevlar used invaluable in a wide array of applications.

Protective Gear: Saving Lives with Kevlar

One of the most well-known applications of Kevlar used is in protective gear, particularly body armor. Bulletproof vests, helmets, and other protective clothing rely on Kevlar’s ability to stop projectiles. The fibers absorb and disperse the impact energy, preventing it from penetrating the wearer’s body. This has saved countless lives in law enforcement, military, and security sectors.

Beyond ballistic protection, Kevlar used in gloves and sleeves protects workers from cuts, abrasions, and heat in industries such as manufacturing, construction, and glass handling. Firefighters also rely on Kevlar-reinforced gear for protection against flames and extreme temperatures. [See also: Fire Resistant Clothing Materials]

Kevlar in Transportation: Enhancing Safety and Performance

The transportation industry utilizes Kevlar used in various ways to enhance safety and performance. In the automotive sector, Kevlar is incorporated into tires to improve strength and durability, reducing the risk of blowouts. It’s also used in brake pads for its heat resistance and friction properties, contributing to safer braking systems.

In aerospace, Kevlar used in aircraft components, such as fuselage panels and engine parts, reduces weight without compromising strength. This leads to improved fuel efficiency and performance. Similarly, in marine applications, Kevlar is used in boat hulls for its strength and resistance to water damage. Its lightweight nature contributes to faster speeds and better maneuverability.

Industrial Applications: Strength and Durability in Demanding Environments

The industrial sector benefits significantly from the properties of Kevlar used. It’s employed in ropes and cables for lifting heavy loads in construction and offshore operations. Its high tensile strength and resistance to stretching make it a reliable choice for these demanding applications.

Furthermore, Kevlar used in conveyor belts, hoses, and other industrial components provides enhanced durability and resistance to wear and tear. This reduces maintenance costs and extends the lifespan of equipment. The chemical resistance of Kevlar also makes it suitable for use in chemical processing plants and other harsh environments.

Sports and Recreation: Performance Enhancement and Safety

Kevlar used isn’t limited to industrial and protective applications; it also finds its way into the world of sports and recreation. Its lightweight and high-strength properties make it ideal for enhancing performance and safety in various activities.

In cycling, Kevlar is used in tires to provide puncture resistance and improve rolling efficiency. In tennis and other racquet sports, it’s incorporated into racquet frames to increase power and control. Skateboarders and snowboarders may wear Kevlar-reinforced protective gear to minimize the risk of injury. Its use in sporting goods underlines its versatility.

Medical Applications: Innovative Solutions for Healthcare

The medical field is also exploring the potential of Kevlar used in various applications. Its biocompatibility and strength make it suitable for use in surgical implants and prosthetic devices. It can be used to reinforce bone cement or to create lightweight, durable prosthetic limbs.

Researchers are also investigating the use of Kevlar used in drug delivery systems and wound dressings. Its ability to be formed into various shapes and its inertness make it a promising material for these applications. The future of Kevlar in medicine holds great potential for improving patient outcomes.

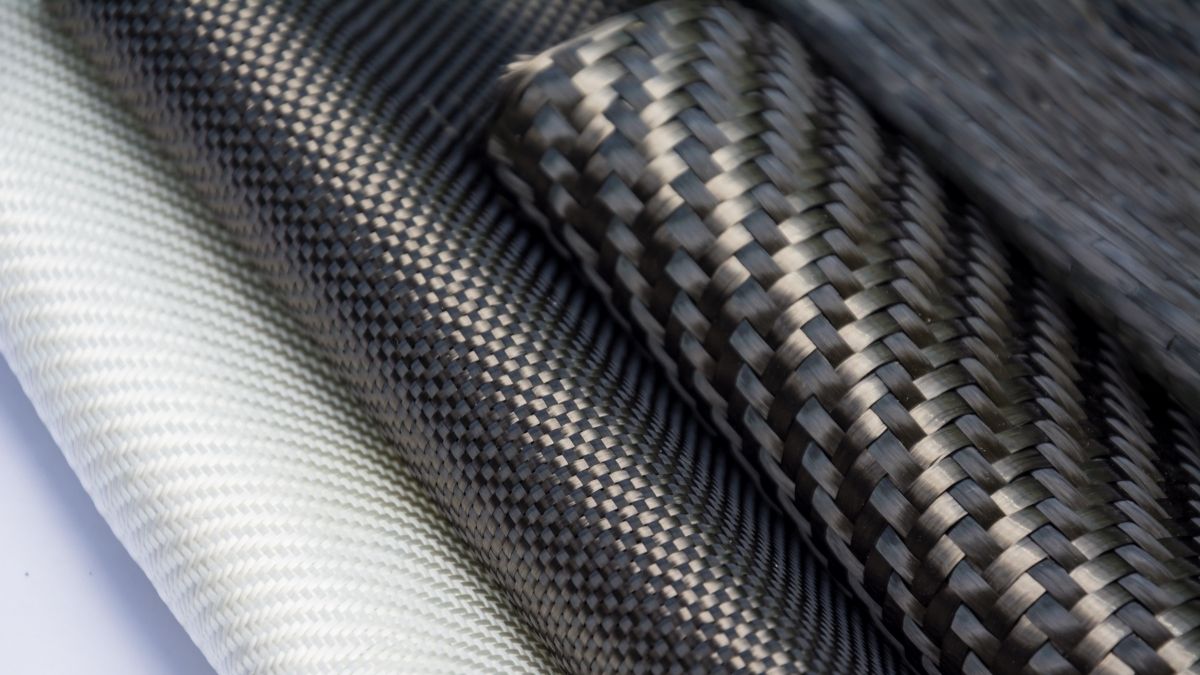

Kevlar in Composites: Combining Strengths for Superior Performance

Kevlar used is often combined with other materials to create composite materials with enhanced properties. These composites leverage the strengths of both Kevlar and the other materials to achieve superior performance in specific applications.

For example, Kevlar-reinforced plastics are used in automotive and aerospace components to reduce weight and increase strength. Kevlar-carbon fiber composites offer an even greater strength-to-weight ratio, making them ideal for high-performance applications such as racing cars and aircraft. The versatility of Kevlar in composites allows for tailored solutions to meet specific performance requirements.

Challenges and Future Trends in Kevlar Use

While Kevlar used offers numerous advantages, it also presents some challenges. Its cost can be a barrier to entry in some applications. Additionally, Kevlar can be difficult to cut and process, requiring specialized equipment and techniques. The environmental impact of its production and disposal is also a growing concern.

Despite these challenges, the future of Kevlar looks promising. Ongoing research is focused on developing more sustainable production methods, improving its processability, and reducing its cost. New applications are also being explored, such as in energy storage devices and flexible electronics. As technology advances, Kevlar used will likely continue to evolve and find new applications in various industries.

Conclusion: The Enduring Legacy of Kevlar

From protecting lives on the battlefield to enhancing performance on the racetrack, Kevlar used has had a profound impact on numerous industries. Its unique combination of strength, lightweight, and resistance to heat and chemicals makes it an invaluable material for a wide range of applications. As technology continues to evolve, the legacy of Kevlar used will undoubtedly endure, shaping the future of materials science and engineering. [See also: Advanced Materials Science Research]

The ongoing innovation surrounding Kevlar ensures its continued relevance and adaptation to emerging needs. Its versatility and proven performance guarantee its place as a cornerstone material in diverse fields for years to come. The remarkable story of Kevlar used is a testament to the power of scientific discovery and its transformative impact on the world.