Kevlar Used: Exploring the Versatile Applications of This Super-Strong Material

Kevlar, a name synonymous with strength and resilience, has become an indispensable material across a surprisingly diverse range of industries. From protecting law enforcement officers to enhancing the performance of sporting equipment, the unique properties of Kevlar used in countless applications have revolutionized safety and performance standards. This article delves into the fascinating world of Kevlar used, exploring its history, properties, and the many ways it impacts our lives.

The History and Development of Kevlar

The story of Kevlar used begins in 1965 with Stephanie Kwolek, a chemist at DuPont. While working on new polymers, Kwolek stumbled upon a solution that, despite its unusual appearance, exhibited exceptional strength and stiffness. This discovery eventually led to the development of Kevlar used, a para-aramid synthetic fiber that would transform industries worldwide. Commercial production of Kevlar used began in 1971, and its impact was immediately felt in applications requiring high strength and low weight.

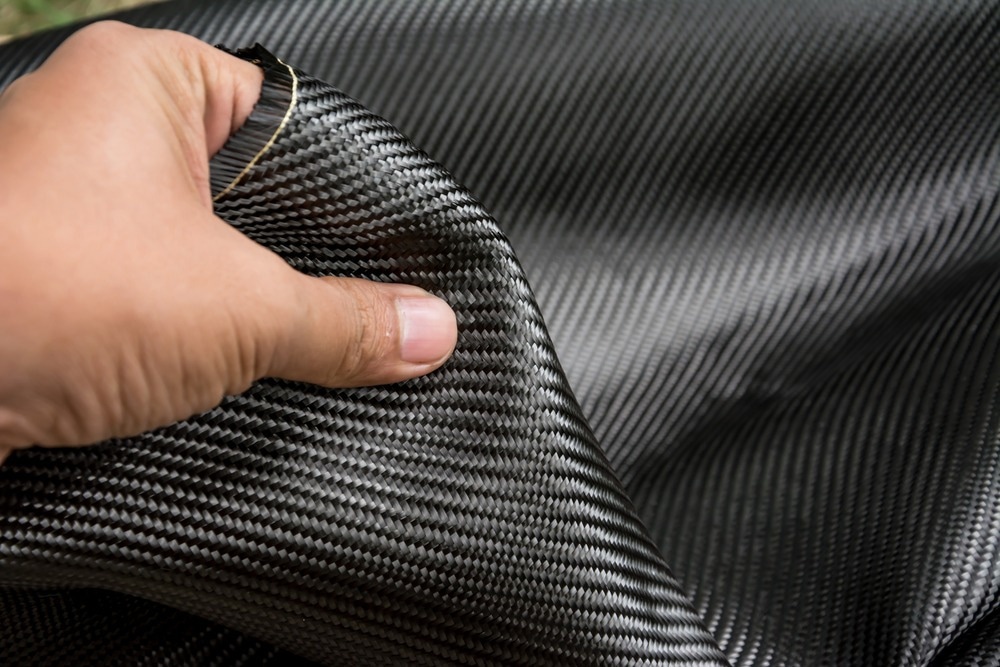

Understanding the Properties of Kevlar

The remarkable properties of Kevlar used stem from its unique molecular structure. The long, rigid polymer chains are highly oriented, resulting in exceptional tensile strength – roughly five times stronger than steel on an equal weight basis. In addition to its strength, Kevlar used exhibits high heat resistance, chemical resistance, and impact resistance, making it suitable for demanding environments. Its lightweight nature further enhances its versatility, allowing for applications where minimizing weight is crucial.

Key Properties:

- High Tensile Strength: Exceptional resistance to stretching and breaking.

- High Heat Resistance: Can withstand high temperatures without degrading.

- Chemical Resistance: Resistant to a wide range of chemicals.

- Impact Resistance: Absorbs and dissipates energy from impacts.

- Lightweight: Significantly lighter than steel, aluminum, and other materials.

Applications of Kevlar Used

The unique combination of properties of Kevlar used makes it invaluable in a wide array of applications. Here are some of the most prominent examples:

Body Armor and Ballistic Protection

Perhaps the most well-known application of Kevlar used is in body armor. Its high tensile strength and impact resistance make it ideal for bulletproof vests and other protective gear. Kevlar used in body armor works by absorbing and dispersing the energy of a projectile, preventing it from penetrating the wearer’s body. This application has saved countless lives in law enforcement, military, and security operations.

Protective Gloves and Apparel

Beyond body armor, Kevlar used in protective gloves and apparel provides cut and abrasion resistance for workers in various industries. Construction workers, mechanics, and healthcare professionals benefit from Kevlar used in gloves to protect their hands from sharp objects and hazardous materials. Similarly, firefighters and other first responders rely on Kevlar used in their protective clothing to shield them from heat, flames, and sharp debris. [See also: Fire Resistant Clothing Materials]

Tires and Automotive Components

Kevlar used as a reinforcing material in tires enhances their strength, durability, and resistance to punctures. The addition of Kevlar used to tire construction improves handling, reduces rolling resistance, and extends tire life. In addition to tires, Kevlar used in other automotive components, such as brake pads and clutch linings, improves their performance and longevity.

Ropes and Cables

The high tensile strength and low stretch of Kevlar used make it an excellent material for ropes and cables. Kevlar used in ropes and cables are used in a variety of applications, including mooring lines for ships, suspension cables for bridges, and tow ropes for vehicles. Its lightweight nature also makes it ideal for applications where weight is a concern, such as in aerospace and marine industries.

Sporting Goods

Kevlar used in sporting goods enhances the performance and durability of equipment such as skis, snowboards, tennis rackets, and kayaks. The addition of Kevlar used to these products increases their strength, stiffness, and resistance to impact damage. This allows athletes to push their limits without compromising the integrity of their equipment. For instance, Kevlar used in hockey sticks increases their strength, enabling players to take powerful shots without fear of breaking the stick.

Aerospace Applications

The lightweight and high-strength properties of Kevlar used make it an attractive material for aerospace applications. Kevlar used in aircraft components, such as interior panels and structural reinforcements, reduces weight and improves fuel efficiency. Its resistance to heat and chemicals also makes it suitable for use in harsh environments. In addition, Kevlar used in spacecraft components provides protection against micrometeoroids and other space debris.

Medical Applications

While less common, Kevlar used is finding increasing applications in the medical field. Its biocompatibility and strength make it suitable for use in surgical implants and prosthetic devices. Kevlar used in sutures provides high tensile strength for wound closure, while Kevlar used in prosthetic limbs provides support and durability. Research is ongoing to explore further medical applications of Kevlar used, such as in drug delivery systems and tissue engineering.

The Future of Kevlar Used

The future of Kevlar used looks bright, with ongoing research and development focused on improving its properties and expanding its applications. Researchers are exploring new ways to enhance its strength, heat resistance, and chemical resistance. They are also working on developing new forms of Kevlar used, such as nanofibers and nanocomposites, which offer even greater potential for innovation. As technology advances, Kevlar used will continue to play a vital role in protecting people, enhancing performance, and pushing the boundaries of what is possible.

Environmental Considerations of Kevlar

While Kevlar used offers numerous benefits, it’s important to consider its environmental impact. The production of Kevlar used involves the use of chemicals and energy, which can contribute to pollution and greenhouse gas emissions. However, efforts are being made to improve the sustainability of Kevlar used production, such as using more environmentally friendly chemicals and reducing energy consumption. Recycling Kevlar used is also a challenge, but researchers are exploring new methods for breaking down and reusing the material. [See also: Sustainable Materials in Manufacturing]

Conclusion: The Enduring Legacy of Kevlar

From its humble beginnings in a DuPont laboratory to its widespread use in life-saving applications, Kevlar used has had a profound impact on society. Its unique combination of strength, durability, and lightweight properties has made it an indispensable material across a wide range of industries. As technology continues to evolve, Kevlar used will undoubtedly remain at the forefront of innovation, protecting people and enhancing performance for generations to come. The story of Kevlar used is a testament to the power of scientific discovery and the ingenuity of human innovation. The applications of Kevlar used are only limited by our imagination, and its enduring legacy is assured.