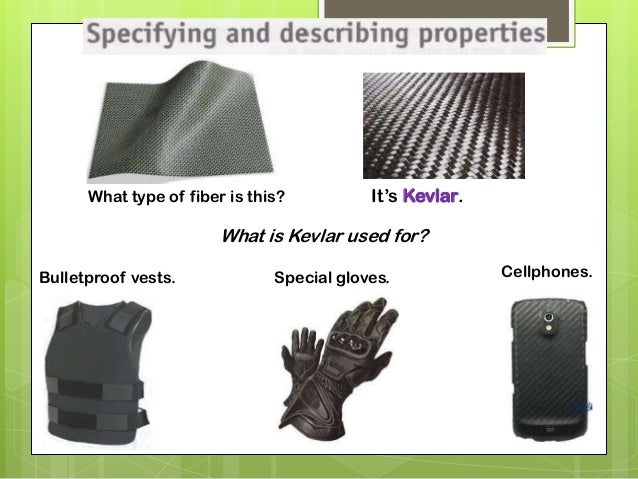

Kevlar Used: Exploring the Versatile Applications of This High-Strength Material

Kevlar, a name synonymous with strength and resilience, has become an indispensable material across a wide spectrum of industries. From bulletproof vests safeguarding law enforcement officers to high-performance tires enhancing vehicle safety, the applications of kevlar used are as diverse as they are crucial. This article delves into the fascinating world of kevlar used, exploring its unique properties, its various applications, and its impact on modern technology and safety.

Understanding Kevlar: The Science Behind the Strength

Kevlar is a para-aramid synthetic fiber, renowned for its exceptional tensile strength-to-weight ratio. Developed by Stephanie Kwolek at DuPont in 1965, it was first commercially introduced in 1971. Its remarkable properties stem from its molecular structure: long, rigid polymer chains oriented parallel to each other, resulting in a highly ordered and crystalline structure. This arrangement allows kevlar used to withstand immense stress and tension without breaking. Unlike steel, which can deform under pressure, kevlar fibers maintain their shape and integrity even under extreme conditions.

Key Properties of Kevlar

- High Tensile Strength: Kevlar boasts an incredibly high tensile strength, approximately five times stronger than steel on an equal weight basis.

- Heat Resistance: Kevlar exhibits excellent resistance to high temperatures, making it suitable for applications in demanding thermal environments.

- Chemical Resistance: Kevlar is resistant to many chemicals, including acids and bases, further expanding its range of applications.

- Lightweight: Despite its exceptional strength, kevlar is remarkably lightweight, contributing to its versatility in various applications.

- Cut Resistance: Kevlar provides excellent cut resistance, making it ideal for protective gear and industrial applications.

The Diverse Applications of Kevlar Used

The unique combination of strength, heat resistance, and lightweight properties makes kevlar used a preferred material in numerous industries. From personal protection to aerospace engineering, kevlar plays a critical role in enhancing safety, performance, and durability.

Personal Protective Equipment

Perhaps the most well-known application of kevlar used is in bulletproof vests. Its ability to absorb and dissipate the energy of a projectile makes it a life-saving material for law enforcement officers, military personnel, and security guards. Kevlar is also used in other protective gear, such as gloves, sleeves, and helmets, to protect workers from cuts, abrasions, and impacts in hazardous environments. [See also: Body Armor Evolution: From Steel to Advanced Composites]

Aerospace Applications

The lightweight and high-strength properties of kevlar make it an ideal material for aerospace applications. It is used in aircraft components such as fuselage panels, rotor blades, and engine housings to reduce weight and improve fuel efficiency. Kevlar also enhances the structural integrity of aircraft, making them more resistant to impact and damage. In spacecraft, kevlar used contributes to shielding against micrometeoroids and space debris.

Automotive Industry

In the automotive industry, kevlar used in tires to enhance their strength, durability, and puncture resistance. Kevlar belts and hoses improve the performance and longevity of engine components. High-performance brake pads also incorporate kevlar fibers for increased stopping power and reduced wear. Furthermore, some automotive manufacturers are exploring the use of kevlar in body panels to reduce weight and improve fuel economy. [See also: The Future of Automotive Materials: Lightweighting and Sustainability]

Sporting Goods

Kevlar finds its way into various sporting goods where strength and lightweight are crucial. It is used in racing sails to improve performance and durability, in bicycle tires for puncture resistance, and in protective gear for sports such as hockey and skateboarding. Kevlar used in tennis rackets and golf clubs enhances their strength and responsiveness. The use of kevlar in these applications allows athletes to push their limits and achieve peak performance.

Industrial Applications

The industrial sector benefits greatly from the unique properties of kevlar used. It is employed in high-strength ropes and cables for lifting heavy loads, in conveyor belts for transporting materials, and in protective clothing for workers in hazardous environments. Kevlar also enhances the durability and lifespan of industrial machinery and equipment.

Marine Applications

In marine environments, kevlar used in boat hulls and sails to improve their strength, durability, and resistance to damage. Kevlar ropes and cables are used for mooring and towing, providing exceptional strength and reliability in harsh marine conditions. The use of kevlar in marine applications enhances the safety and performance of vessels.

Advantages and Disadvantages of Using Kevlar

While kevlar offers numerous advantages, it also has some limitations that need to be considered when selecting materials for specific applications.

Advantages

- High Strength-to-Weight Ratio: Provides exceptional strength without adding significant weight.

- Heat Resistance: Withstands high temperatures without significant degradation.

- Chemical Resistance: Resistant to many chemicals, extending its lifespan in harsh environments.

- Cut Resistance: Offers excellent protection against cuts and abrasions.

- Impact Resistance: Absorbs and dissipates impact energy, reducing the risk of injury.

Disadvantages

- Cost: Kevlar is generally more expensive than other materials, such as steel or nylon.

- UV Degradation: Prolonged exposure to ultraviolet (UV) light can degrade kevlar fibers, reducing their strength.

- Moisture Absorption: Kevlar can absorb moisture, which can affect its properties and performance.

- Difficult to Cut and Machine: Kevlar’s high strength makes it difficult to cut and machine, requiring specialized tools and techniques.

The Future of Kevlar Used

Research and development efforts are continuously exploring new ways to enhance the properties and applications of kevlar. Scientists are working on improving its UV resistance, reducing its moisture absorption, and developing new manufacturing processes to lower its cost. The future of kevlar used is promising, with potential applications in areas such as energy storage, biomedical devices, and advanced composites. [See also: Advanced Materials: Shaping the Future of Innovation]

The ongoing advancements in kevlar technology will undoubtedly lead to even more innovative and life-saving applications in the years to come. As industries continue to demand materials that are both strong and lightweight, kevlar will remain at the forefront of materials science, playing a vital role in shaping the future of technology and safety.

In conclusion, kevlar used represents a remarkable achievement in materials science, offering a unique combination of strength, heat resistance, and lightweight properties. Its diverse applications across various industries demonstrate its versatility and importance in enhancing safety, performance, and durability. From protecting law enforcement officers to improving the efficiency of aircraft, kevlar continues to make a significant impact on our world, and its future remains bright with possibilities.