Kevlar Used: Exploring the Versatile Applications of Aramid Fiber

Kevlar, a name synonymous with strength and durability, has become a household term, albeit often associated with bulletproof vests. However, the reality is that Kevlar used far extends beyond personal protection. This remarkable material, a para-aramid synthetic fiber, boasts a unique combination of high tensile strength and lightweight properties, making it ideal for a vast array of applications. From aerospace engineering to sporting goods, Kevlar used has revolutionized industries and continues to inspire innovation. This article delves into the diverse ways Kevlar is used, highlighting its key characteristics and the impact it has had on various sectors.

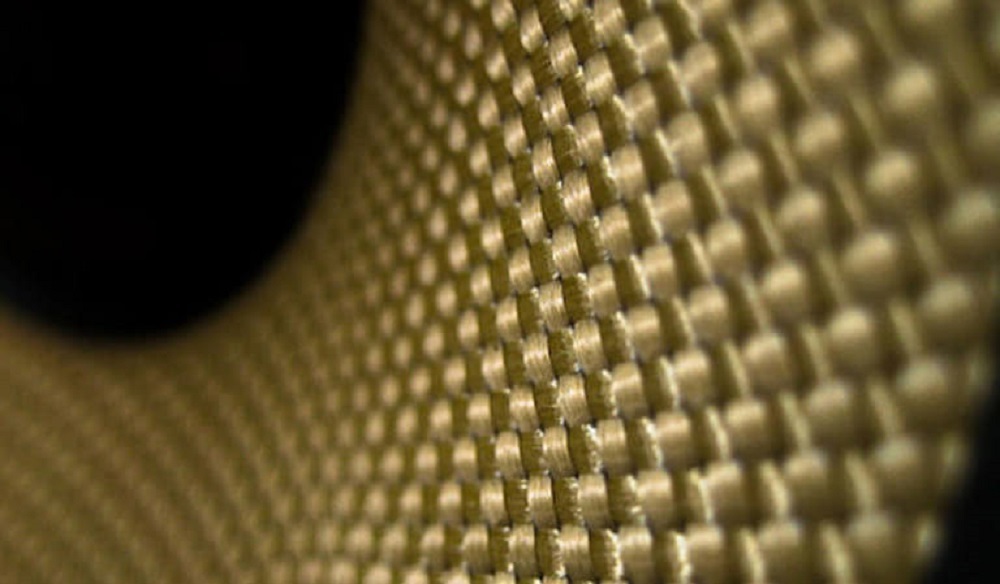

What is Kevlar and Why is it Special?

Developed by Stephanie Kwolek at DuPont in 1965, Kevlar is characterized by its tightly packed molecular structure, which allows it to withstand extreme forces. Its high tensile strength-to-weight ratio makes it approximately five times stronger than steel on an equal-weight basis. This exceptional strength, coupled with its resistance to heat and chemical degradation, makes Kevlar used a preferred material in demanding environments. Unlike many other high-strength materials, Kevlar also exhibits good resistance to organic solvents. This combination of properties allows for a broad spectrum of applications.

Personal Protection: The Iconic Use of Kevlar

Perhaps the most well-known application of Kevlar used is in personal protective equipment, especially bulletproof vests and body armor. Its ability to absorb and dissipate the energy of projectiles makes it an essential component in safeguarding law enforcement officers, military personnel, and security professionals. The layered structure of Kevlar fabric effectively traps bullets and fragments, minimizing the risk of penetration and injury. Beyond vests, Kevlar is also used in helmets, gloves, and other protective gear.

Aerospace Applications: Lightweight Strength for Flight

The aerospace industry benefits significantly from the lightweight strength of Kevlar. It is used in aircraft components, such as fuselage panels, rotor blades, and engine housings, to reduce weight and improve fuel efficiency. The high strength and stiffness of Kevlar also contribute to the structural integrity of aircraft, enhancing safety and performance. Furthermore, its resistance to high temperatures makes it suitable for use in engine components and other areas exposed to extreme heat. [See also: Composite Materials in Aerospace]

Automotive Industry: Enhancing Safety and Performance

In the automotive sector, Kevlar used is becoming increasingly prevalent. It is incorporated into tires to enhance their strength and durability, improving handling and reducing the risk of punctures. Kevlar is also used in brake pads to improve stopping power and reduce wear. Furthermore, it can be found in clutch linings and other components to enhance performance and longevity. Some high-performance vehicles also utilize Kevlar in body panels to reduce weight and improve aerodynamics.

Marine Applications: Strength and Durability in Harsh Environments

The marine environment presents unique challenges for materials, including exposure to saltwater, UV radiation, and constant stress. Kevlar used excels in these conditions due to its resistance to corrosion and degradation. It is commonly used in ropes, cables, and hulls of boats and ships to provide strength and durability. The use of Kevlar in marine applications enhances the safety and reliability of vessels, contributing to improved performance and reduced maintenance costs.

Sporting Goods: Performance Enhancement and Safety

From tennis rackets to bicycle tires, Kevlar used in sporting goods enhances performance and safety. Its high strength and lightweight properties make it ideal for applications where both factors are critical. In tennis rackets, Kevlar is used to increase stiffness and power, while in bicycle tires, it provides puncture resistance and improved handling. The use of Kevlar in sporting goods allows athletes to push their limits with greater confidence and safety. [See also: Advanced Materials in Sports Equipment]

Industrial Applications: Strength and Reliability for Demanding Tasks

Numerous industrial applications benefit from the exceptional properties of Kevlar. It is used in conveyor belts, hoses, and protective clothing to provide strength, durability, and resistance to wear and tear. The use of Kevlar in these applications enhances productivity and reduces the risk of accidents. Furthermore, its resistance to chemicals and high temperatures makes it suitable for use in harsh industrial environments. Kevlar used in industrial settings contributes to improved safety, efficiency, and reliability.

Medical Applications: Biocompatibility and Strength

While less widely known, Kevlar also finds applications in the medical field. Its biocompatibility and high strength make it suitable for use in surgical implants and prosthetic devices. Kevlar can be used as a reinforcing material in bone cement and other orthopedic applications. Furthermore, it is being explored for use in drug delivery systems and other advanced medical technologies. [See also: Biomaterials in Medical Implants]

Beyond Traditional Uses: Innovative Applications of Kevlar

The unique properties of Kevlar continue to inspire innovation, leading to new and unexpected applications. Researchers are exploring its use in areas such as bridge construction, earthquake-resistant buildings, and even space elevators. The possibilities for Kevlar used are virtually limitless, as engineers and scientists continue to discover new ways to harness its exceptional strength and versatility. The future of Kevlar is bright, with ongoing research and development promising even more groundbreaking applications.

The Future of Kevlar: Sustainable and Advanced Materials

As sustainability becomes increasingly important, research is focusing on developing more environmentally friendly versions of Kevlar and exploring recycling options. Additionally, ongoing research aims to further enhance the properties of Kevlar, such as its resistance to UV degradation and moisture absorption. The future of Kevlar lies in developing sustainable and advanced materials that can meet the ever-evolving needs of various industries. The continued innovation in Kevlar used ensures its position as a leading material for decades to come.

Conclusion: The Enduring Legacy of Kevlar

From its origins as a revolutionary material for bulletproof vests to its diverse applications across numerous industries, Kevlar used has left an indelible mark on the world. Its exceptional strength, lightweight properties, and resistance to harsh environments have made it an indispensable material for personal protection, aerospace engineering, automotive manufacturing, and countless other applications. As research and development continue to push the boundaries of what is possible, the future of Kevlar promises even more groundbreaking innovations and applications. The enduring legacy of Kevlar lies in its ability to protect, enhance, and inspire, making it a truly remarkable material.