Kevlar Used: Exploring the Diverse Applications of This Super-Strong Material

Kevlar, a name synonymous with strength and resilience, is a para-aramid synthetic fiber, five times stronger than steel on an equal weight basis. Discovered by Stephanie Kwolek at DuPont in 1965, its exceptional properties have led to its widespread adoption across numerous industries. This article delves into the diverse applications of kevlar used today, exploring its role in enhancing safety, performance, and innovation.

A Brief History of Kevlar

Stephanie Kwolek’s groundbreaking discovery revolutionized material science. While searching for a new lightweight tire cord material, she synthesized a liquid crystalline polymer solution that, when spun, formed fibers of unprecedented strength and stiffness. DuPont commercialized kevlar in the early 1970s, and it quickly found applications in areas requiring high tensile strength and heat resistance.

Applications in Personal Protective Equipment

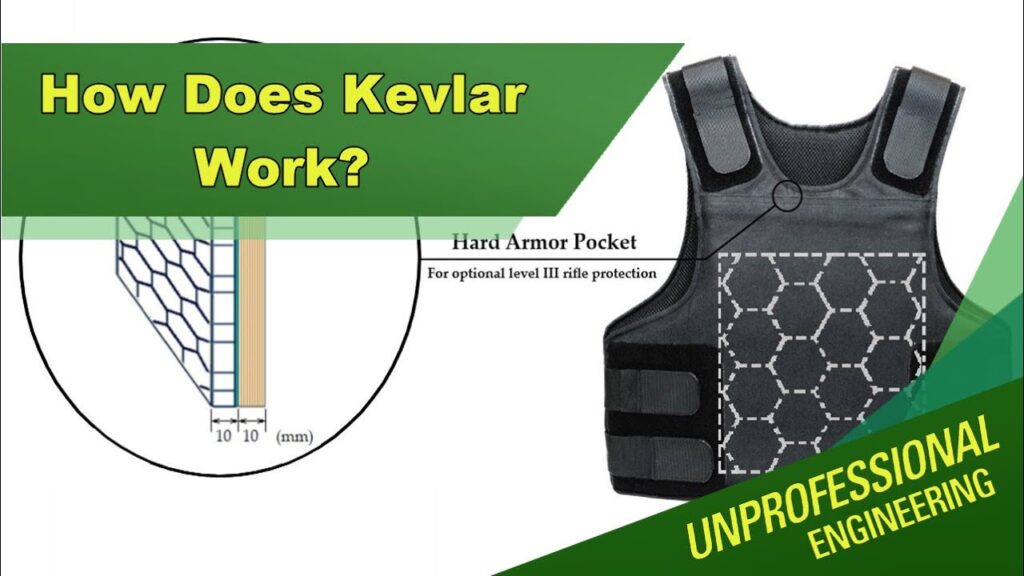

One of the most well-known applications of kevlar used is in personal protective equipment, particularly bulletproof vests. Kevlar‘s ability to absorb and dissipate energy makes it an ideal material for ballistic protection. When a bullet strikes a kevlar vest, the fibers spread the impact force over a larger area, preventing penetration and minimizing injury. Beyond bulletproof vests, kevlar is also used in:

- Cut-resistant gloves: Protecting workers in industries like manufacturing and food processing.

- Motorcycle apparel: Providing abrasion resistance in jackets, pants, and gloves.

- Helmets: Enhancing the impact resistance of helmets used in sports, construction, and military applications.

Kevlar Used in the Automotive Industry

The automotive industry utilizes kevlar in several ways to improve vehicle performance and safety. Its lightweight and high-strength properties make it an attractive alternative to traditional materials like steel. Kevlar used in automotive applications include:

- Tires: As a reinforcing material in tire construction, improving strength, durability, and resistance to punctures.

- Brake pads: Enhancing braking performance and reducing wear.

- Clutch linings: Providing improved friction and heat resistance.

- Composite body panels: Reducing vehicle weight and improving fuel efficiency.

Aerospace Applications

The aerospace industry demands materials that are both lightweight and strong. Kevlar used in aircraft components helps to reduce weight, improve fuel efficiency, and enhance structural integrity. Specific applications include:

- Aircraft panels: Reducing weight and improving structural performance.

- Helicopter rotor blades: Providing high strength and fatigue resistance.

- Pressure vessels: Containing pressurized gases and liquids in spacecraft.

Marine Applications

In the marine environment, kevlar used offers excellent resistance to saltwater corrosion and degradation. This makes it suitable for a variety of marine applications, such as:

- Boat hulls: Improving strength, stiffness, and impact resistance.

- Sails: Providing high tensile strength and tear resistance in high-performance sails.

- Ropes and cables: Offering superior strength and durability in mooring lines, tow ropes, and other marine cables.

Kevlar in Sports Equipment

The unique properties of kevlar make it a valuable material in sports equipment, enhancing performance and safety. Examples include:

- Tennis rackets: Improving frame stiffness and power.

- Skis and snowboards: Enhancing torsional stiffness and edge grip.

- Kayaks and canoes: Providing lightweight strength and impact resistance.

- Protective gear: Used in padding and reinforcement for various sports, such as hockey and football.

Industrial Applications of Kevlar

Beyond the consumer-facing applications, kevlar used extensively in various industrial settings where high strength, heat resistance, and chemical resistance are crucial. These applications include:

- Fiber optic cables: Providing strength and protection to delicate optical fibers.

- Reinforced concrete: Improving the tensile strength and durability of concrete structures.

- High-pressure hoses: Withstanding high internal pressures in hydraulic systems.

- Conveyor belts: Enhancing the strength and tear resistance of conveyor belts used in mining and manufacturing.

The Future of Kevlar

The future of kevlar used looks promising, with ongoing research and development focused on improving its properties and expanding its applications. Some potential areas of future development include:

- Enhanced ballistic protection: Developing lighter and more effective body armor.

- Advanced composites: Creating new composite materials with improved strength, stiffness, and toughness.

- Biomedical applications: Exploring the use of kevlar in medical implants and devices.

- Sustainable alternatives: Researching bio-based alternatives to kevlar to reduce its environmental impact.

Kevlar: A Material Shaping the Modern World

From protecting law enforcement officers to enhancing the performance of athletes, kevlar has become an indispensable material in countless applications. Its unique combination of strength, lightweight, and resistance to heat and chemicals makes it a valuable asset in a wide range of industries. As technology continues to advance, we can expect to see even more innovative uses for kevlar in the years to come. The versatility of kevlar used is a testament to its impact on modern engineering and design. The future will surely see even more applications for kevlar. The material’s impact is undeniable. Its resilience and adaptability make kevlar an invaluable asset across various sectors. The impact of kevlar used extends beyond immediate safety applications. Its contribution to technological advancements and material science is significant. Kevlar continues to be a key component in protective gear and various industrial uses. The widespread kevlar used demonstrates its reliability and effectiveness. It remains a staple in many industries due to its unique properties. The continuous innovation surrounding kevlar promises even greater advancements in material science. Kevlar‘s role in enhancing safety and performance is unmatched, proving its importance in modern technology. The extensive kevlar used underscores its value. [See also: The Science Behind Bulletproof Vests] [See also: Advanced Materials in Aerospace Engineering] [See also: The Future of Composite Materials]