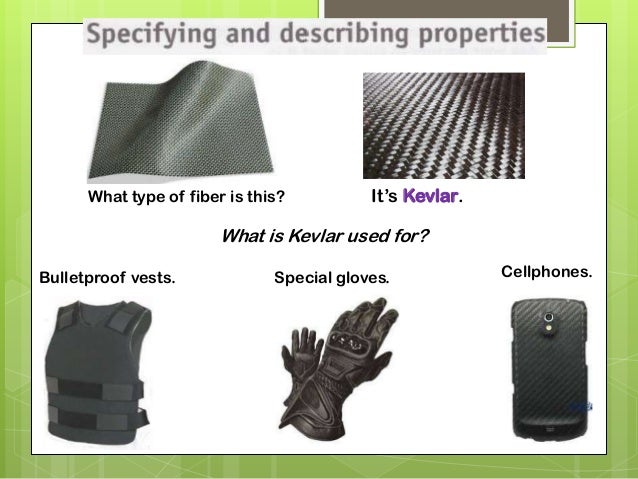

Kevlar Used: Exploring the Diverse Applications of This Super-Strong Material

Kevlar, a name synonymous with strength and resilience, has become an indispensable material across a wide range of industries. From protecting law enforcement officers and military personnel to enhancing the performance of sporting equipment and even contributing to space exploration, the applications of Kevlar are remarkably diverse. This article delves into the various ways Kevlar is used, highlighting its unique properties and the impact it has had on modern technology and safety.

What is Kevlar? A Brief Overview

Kevlar is a para-aramid synthetic fiber, meaning it’s a strong, heat-resistant synthetic fiber. Discovered in 1965 by Stephanie Kwolek at DuPont, Kevlar’s exceptional tensile strength-to-weight ratio makes it five times stronger than steel on an equal-weight basis. This remarkable property stems from its tightly packed molecular structure, which allows it to withstand immense forces without breaking. The strength of Kevlar comes from the inter-chain bonds which form between the molecules, making the material incredibly strong and resistant to heat and chemical degradation. [See also: The History of Aramid Fibers]

Protection and Safety Applications of Kevlar

Body Armor: Saving Lives on the Front Lines

Perhaps the most well-known application of Kevlar is in body armor. Bulletproof vests made with Kevlar have saved countless lives by providing reliable protection against ballistic threats. The fiber’s ability to absorb and dissipate the energy of a projectile makes it an ideal material for this critical application. Kevlar vests are standard issue for law enforcement, military personnel, and security professionals worldwide. The material is also used in helmets and other protective gear. New advancements in Kevlar technology continue to improve the comfort and effectiveness of body armor.

Protective Gloves: A Shield Against Workplace Hazards

Beyond body armor, Kevlar is also used in protective gloves for various industries. These gloves provide exceptional cut and abrasion resistance, safeguarding workers from sharp objects, machinery, and other workplace hazards. Construction workers, metal fabricators, and glass handlers all rely on Kevlar gloves to minimize the risk of injuries. The gloves are also used in the medical field to protect against needle sticks and other sharp-instrument injuries.

Vehicle Armor: Fortifying Against Threats

Kevlar is not limited to personal protection; it’s also used to armor vehicles. Military vehicles, armored cars, and even civilian vehicles can be fortified with Kevlar to enhance their resistance to ballistic attacks and explosions. This application is particularly important in conflict zones and high-risk environments, providing occupants with a greater chance of survival. The material is often layered with other materials to create a composite armor system.

Industrial Applications of Kevlar

Reinforcement in Composites: Enhancing Strength and Durability

Kevlar is widely used as a reinforcing material in composite materials. When combined with resins or other polymers, Kevlar significantly enhances the strength, stiffness, and impact resistance of the resulting composite. This makes it ideal for applications in aerospace, automotive, and marine industries. The lightweight nature of Kevlar also contributes to improved fuel efficiency in vehicles and aircraft.

Tires and Rubber Products: Improving Performance and Longevity

Kevlar is incorporated into tires and other rubber products to improve their performance and longevity. In tires, Kevlar enhances puncture resistance, reduces rolling resistance, and improves overall durability. This is particularly beneficial for high-performance vehicles and off-road applications. Kevlar is also used in belts, hoses, and other rubber components to increase their strength and resistance to wear and tear. [See also: The Science Behind Tire Construction]

Fiber Optic Cables: Protecting Delicate Components

Fiber optic cables, which transmit data at high speeds, are vulnerable to damage from bending, stretching, and environmental factors. Kevlar is used as a protective layer around the delicate glass fibers, providing strength and preventing damage during installation and operation. This ensures the reliable transmission of data over long distances. The presence of Kevlar also contributes to the cable’s resistance to moisture and chemical exposure.

Sporting Goods and Recreation

High-Performance Gear: Enhancing Athletic Performance

The strength and lightweight properties of Kevlar make it a popular material in sporting goods. It’s used in tennis rackets, skis, kayaks, and other high-performance equipment to enhance their performance and durability. Kevlar can improve the stiffness and power of a tennis racket, the stability of skis, and the impact resistance of a kayak. Athletes benefit from the enhanced performance and increased longevity of their equipment.

Sails and Ropes: Withstanding Extreme Conditions

In sailing and other marine applications, Kevlar is used in sails and ropes to withstand extreme conditions. Kevlar sails offer exceptional strength and resistance to stretching, allowing for improved performance in windy conditions. Kevlar ropes are also incredibly strong and lightweight, making them ideal for various rigging and mooring applications. The material’s resistance to saltwater degradation is an added benefit in marine environments.

Aerospace and Space Exploration

Aircraft Components: Reducing Weight and Improving Strength

The aerospace industry utilizes Kevlar in various aircraft components to reduce weight and improve strength. Kevlar composites are used in fuselage panels, interior components, and even engine nacelles. The lightweight nature of Kevlar contributes to improved fuel efficiency, while its strength enhances the structural integrity of the aircraft. The material’s resistance to heat and vibration is also crucial in aerospace applications.

Spacecraft Applications: Protecting Against Extreme Environments

Kevlar’s unique properties make it valuable in space exploration. It’s used in spacecraft components, including thermal blankets and debris shields, to protect against extreme temperatures, radiation, and micrometeoroids. Kevlar‘s ability to withstand harsh conditions ensures the safety and reliability of spacecraft during missions. The material has been used in various NASA projects, including the Mars rovers.

Other Notable Applications

Beyond the major categories mentioned above, Kevlar finds applications in a variety of other fields. It’s used in musical instrument strings to enhance their strength and tone, in loudspeakers to improve sound quality, and even in construction materials to reinforce concrete structures. The versatility of Kevlar continues to drive innovation and expand its range of applications.

The Future of Kevlar

As technology advances, researchers are constantly exploring new ways to improve Kevlar and expand its applications. Ongoing research focuses on enhancing its resistance to compression, improving its flexibility, and reducing its cost. New applications are emerging in areas such as medical implants, energy storage, and sustainable construction. The future of Kevlar is bright, with the potential to revolutionize even more industries and improve the safety and performance of countless products.

In conclusion, Kevlar is a remarkable material with a wide array of applications that impact our lives in significant ways. From protecting our law enforcement and military personnel to enhancing the performance of sporting goods and contributing to space exploration, Kevlar’s unique properties make it an invaluable asset across numerous industries. Its strength, lightweight nature, and resistance to extreme conditions ensure its continued relevance in the years to come.