Kevlar Used: Exploring the Diverse Applications of This Super Material

Kevlar, a name synonymous with strength and resilience, has become an indispensable material across a wide spectrum of industries. From safeguarding law enforcement officers to enhancing the performance of sporting equipment, the versatility of Kevlar used in various applications is truly remarkable. This article delves into the fascinating world of Kevlar used, exploring its unique properties, diverse applications, and the impact it has had on modern technology and safety.

What is Kevlar? A Brief Overview

Kevlar is a para-aramid synthetic fiber, known for its high tensile strength-to-weight ratio. Developed by Stephanie Kwolek at DuPont in 1965, it was first commercially introduced in 1971. Its remarkable strength is due to the tightly packed and highly ordered arrangement of its polymer chains, allowing it to withstand significant stress and impact. This unique molecular structure makes Kevlar used a superior alternative to other materials in applications where strength, durability, and heat resistance are crucial.

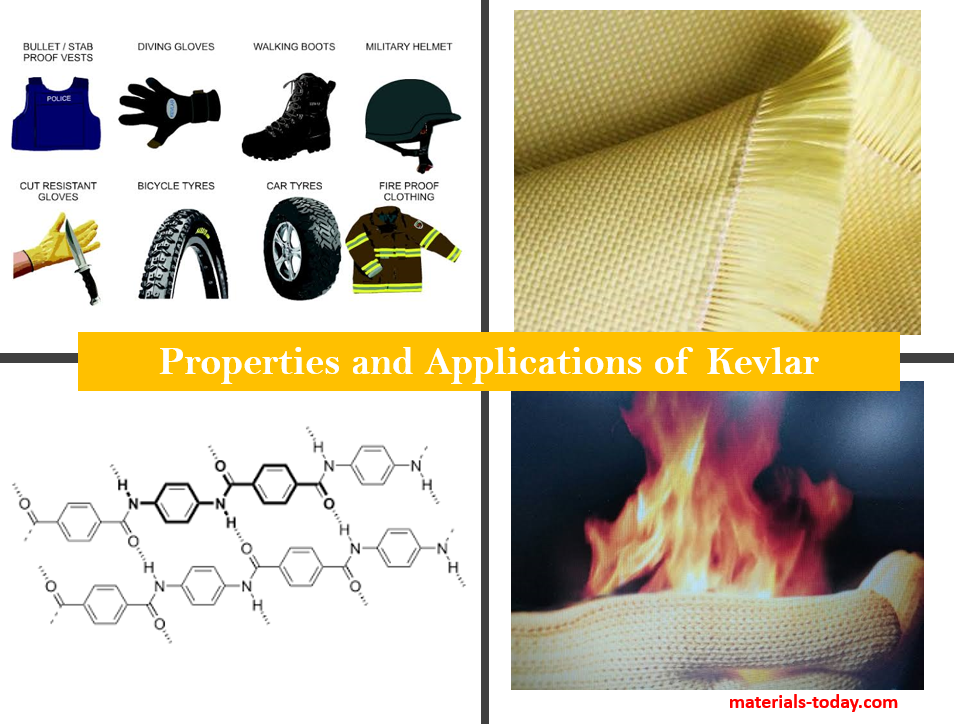

Key Properties of Kevlar

- High Tensile Strength: Kevlar is exceptionally strong, often cited as being five times stronger than steel on an equal weight basis.

- Heat Resistance: It maintains its strength and structural integrity at high temperatures, making it suitable for applications involving heat exposure.

- Chemical Resistance: Kevlar used is resistant to many chemicals, further enhancing its durability in harsh environments.

- Lightweight: Despite its incredible strength, Kevlar is remarkably lightweight, contributing to improved performance and efficiency in various applications.

- Cut and Puncture Resistance: The tightly woven structure of Kevlar used makes it highly resistant to cuts and punctures, providing enhanced protection in safety applications.

Applications of Kevlar: A Deep Dive

The unique properties of Kevlar have led to its widespread adoption across a diverse range of industries. Let’s explore some of the most prominent applications of this remarkable material.

Protective Gear and Body Armor

Perhaps the most well-known application of Kevlar is in the production of body armor and protective gear. Its high tensile strength and cut resistance make it an ideal material for bulletproof vests, providing law enforcement officers, military personnel, and security guards with crucial protection against ballistic threats. Kevlar used in body armor significantly reduces the risk of injury or death from firearms and other projectiles. The lightweight nature of Kevlar also allows for greater mobility and comfort compared to heavier materials.

Beyond body armor, Kevlar used in gloves, sleeves, and other protective clothing for industrial workers who handle sharp objects or work in hazardous environments. [See also: Industrial Safety Gloves: Choosing the Right Protection]

Aerospace Industry

The aerospace industry relies heavily on lightweight, high-strength materials, and Kevlar fits the bill perfectly. Kevlar used in aircraft components, such as fuselage panels and rotor blades, contributing to improved fuel efficiency and overall performance. Its resistance to high temperatures and chemical degradation also makes it suitable for use in engine components and other critical areas.

Furthermore, Kevlar used in the construction of spacecraft and satellites, providing protection against micrometeoroids and other space debris. Its ability to withstand extreme temperatures and radiation makes it an essential material for space exploration.

Automotive Industry

In the automotive industry, Kevlar is employed to enhance safety, performance, and fuel efficiency. Kevlar used in brake pads and clutch linings, improving their durability and performance. Its high heat resistance allows for more efficient braking and reduces the risk of brake fade. Additionally, Kevlar used in tires, increasing their puncture resistance and extending their lifespan.

Furthermore, Kevlar used in vehicle body panels, reducing weight and improving fuel economy. Its high strength-to-weight ratio also contributes to enhanced crashworthiness, protecting occupants in the event of an accident. [See also: Advanced Materials in Automotive Engineering]

Marine Applications

The marine environment presents unique challenges for materials, including exposure to saltwater, UV radiation, and extreme weather conditions. Kevlar‘s resistance to these factors makes it an ideal material for marine applications. Kevlar used in boat hulls, sails, and ropes, providing strength, durability, and resistance to degradation. Its lightweight nature also improves boat performance and fuel efficiency.

Kevlar used in the construction of underwater cables and pipelines, providing protection against corrosion and physical damage. Its high tensile strength ensures the integrity of these critical infrastructure components.

Sporting Goods

The sporting goods industry utilizes Kevlar to enhance the performance and durability of various equipment. Kevlar used in bicycle tires, providing puncture resistance and improving rolling efficiency. Its lightweight nature also contributes to faster acceleration and improved handling. Additionally, Kevlar used in helmets, providing enhanced protection against impact injuries.

Kevlar used in sporting equipment such as tennis rackets, skis, and snowboards, improving their strength, stiffness, and responsiveness. Its ability to withstand high stress and impact forces makes it an essential material for competitive athletes.

Fiber Optic Cables

Fiber optic cables are essential for modern communication networks, and Kevlar plays a crucial role in their construction. Kevlar used as a reinforcing material in fiber optic cables, providing strength and protecting the delicate glass fibers from damage during installation and operation. Its resistance to stretching and bending ensures the integrity of the cables and maintains signal transmission quality. The Kevlar used in this application contributes to the reliability and longevity of communication networks.

The Future of Kevlar Used

As technology continues to advance, the applications of Kevlar are expected to expand even further. Researchers are constantly exploring new ways to utilize its unique properties in diverse fields. Some potential future applications include:

- Medical Implants: Kevlar’s biocompatibility and high strength make it a promising material for medical implants, such as artificial joints and bone replacements.

- Construction Materials: Kevlar could be used to reinforce concrete and other building materials, improving their strength and durability.

- Energy Storage: Kevlar could be used in the development of advanced batteries and fuel cells, improving their performance and safety.

Conclusion

Kevlar used has revolutionized numerous industries with its exceptional strength, durability, and versatility. From protecting law enforcement officers to enhancing the performance of sporting equipment, its applications are vast and ever-expanding. As technology continues to evolve, Kevlar used will undoubtedly play an increasingly important role in shaping the future of materials science and engineering. The ongoing research and development efforts promise even more innovative applications for this remarkable material, solidifying its position as a cornerstone of modern technology.

The future of Kevlar used looks bright, with ongoing research and development paving the way for even more innovative applications. Its unique combination of strength, lightweight nature, and resistance to extreme conditions makes it an indispensable material for a wide range of industries. As we continue to push the boundaries of materials science, Kevlar used will undoubtedly remain at the forefront of innovation.