Kevlar Used: Exploring the Diverse Applications of This Revolutionary Material

Kevlar, a name synonymous with strength and resilience, has revolutionized numerous industries since its invention in 1965 by Stephanie Kwolek at DuPont. This para-aramid synthetic fiber, known for its high tensile strength-to-weight ratio, is approximately five times stronger than steel on an equal weight basis. The unique molecular structure of Kevlar used contributes to its exceptional properties, making it an indispensable material in applications ranging from personal protective equipment to aerospace engineering. This article delves into the diverse ways Kevlar used is implemented across various sectors, highlighting its impact on safety, performance, and innovation.

The Science Behind Kevlar

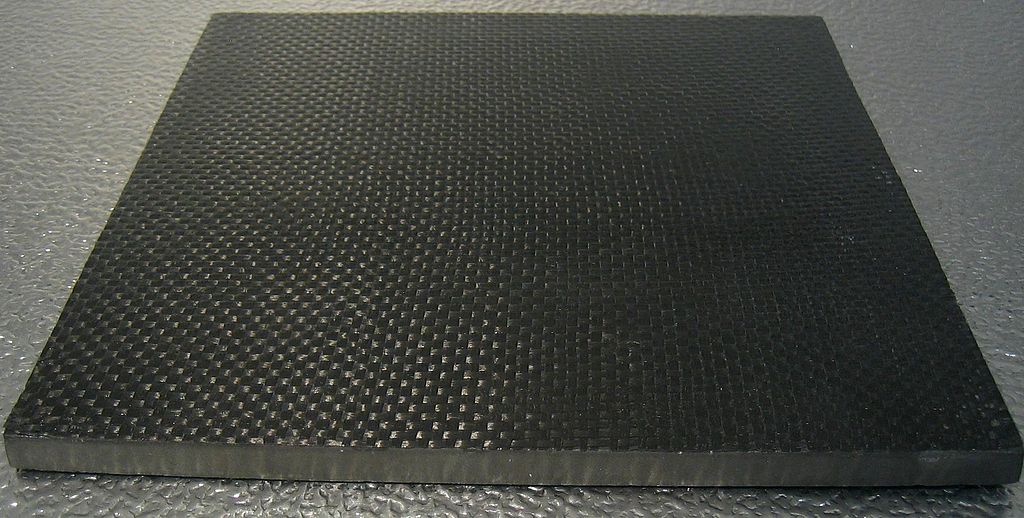

Understanding the widespread applications of Kevlar used requires a basic understanding of its composition. Kevlar used is a polymer, specifically a poly-paraphenylene terephthalamide. The long, rigid molecules of Kevlar used are highly oriented, forming strong intermolecular bonds. This arrangement results in the fiber’s remarkable tensile strength and resistance to heat and chemicals. The manufacturing process involves dissolving the polymer in a solvent and then spinning it into fibers, which are subsequently drawn and heat-treated to enhance their properties.

Personal Protective Equipment: Saving Lives with Kevlar

One of the most well-known applications of Kevlar used is in personal protective equipment (PPE). Bulletproof vests, a critical piece of equipment for law enforcement and military personnel, rely heavily on Kevlar used. The tightly woven fabric layers of Kevlar used are designed to absorb and dissipate the energy of a bullet or other projectile, preventing it from penetrating the wearer’s body. Helmets, gloves, and other protective gear also incorporate Kevlar used to provide enhanced safety in hazardous environments. Its lightweight nature compared to steel makes it a preferred choice for those who need mobility and protection.

Bulletproof Vests: A Closer Look

Bulletproof vests utilizing Kevlar used come in various levels of protection, designed to withstand different types of ammunition. The National Institute of Justice (NIJ) sets standards for body armor, categorizing vests based on their ability to stop specific threats. Kevlar used is instrumental in meeting these standards, offering a balance of protection, comfort, and flexibility. Newer vests often combine Kevlar used with other materials, such as polyethylene, to further enhance their protective capabilities.

Beyond Bulletproof Vests: Other PPE Applications

The use of Kevlar used extends beyond bulletproof vests. Firefighters, for example, wear turnout gear that incorporates Kevlar used to protect them from extreme heat and flames. Industrial workers in environments with sharp objects or machinery often use Kevlar used-reinforced gloves and sleeves to prevent cuts and abrasions. Even motorcycle riders benefit from Kevlar used-lined clothing, which provides abrasion resistance in the event of a crash. [See also: Motorcycle Safety Gear Innovations]

Aerospace and Automotive Industries: Enhancing Performance with Kevlar

The aerospace and automotive industries leverage the unique properties of Kevlar used to enhance performance and safety. In aircraft manufacturing, Kevlar used is used in composite materials for aircraft fuselages and wings. These composites offer a high strength-to-weight ratio, reducing overall weight and improving fuel efficiency. In the automotive sector, Kevlar used is used in brake pads, tires, and other components to improve performance and durability.

Aerospace Applications: Lightweight and Strong

The aerospace industry continually seeks ways to reduce aircraft weight without compromising strength. Kevlar used composites are ideal for this purpose, offering significant weight savings compared to traditional materials like aluminum. These composites are also resistant to corrosion and fatigue, extending the lifespan of aircraft components. The use of Kevlar used in aerospace applications contributes to improved fuel efficiency, reduced emissions, and enhanced safety.

Automotive Applications: Improving Safety and Performance

In the automotive industry, Kevlar used is used in various components to improve safety and performance. Brake pads incorporating Kevlar used offer improved stopping power and reduced wear. Tires reinforced with Kevlar used are more resistant to punctures and offer better handling. Additionally, some high-performance vehicles use Kevlar used in body panels to reduce weight and improve aerodynamics. [See also: Advanced Materials in Automotive Engineering]

Marine Applications: Kevlar in Boats and Ropes

The marine industry also benefits from the use of Kevlar used. Its high strength and resistance to saltwater corrosion make it an ideal material for boat hulls, sails, and ropes. Kevlar used ropes are stronger and lighter than traditional ropes, making them ideal for use in sailing and other marine applications. Kevlar used hulls offer improved durability and resistance to impact damage, enhancing the safety and performance of boats and other watercraft.

High-Performance Sailing Ropes

Sailing ropes made from Kevlar used are prized for their high strength and low stretch. These ropes allow sailors to exert more precise control over their sails, resulting in improved performance. Kevlar used ropes are also resistant to abrasion and UV degradation, ensuring a long lifespan in harsh marine environments. The use of Kevlar used in sailing ropes has revolutionized the sport, allowing sailors to push the limits of performance.

Boat Hull Reinforcement

Kevlar used is also used to reinforce boat hulls, providing increased strength and impact resistance. This is particularly important for high-performance boats that are subjected to extreme conditions. Kevlar used reinforcement can help to prevent hull damage from impacts with rocks or other debris, improving the safety and reliability of the boat. The lightweight nature of Kevlar used also contributes to improved fuel efficiency.

Sports Equipment: Kevlar Used in High-Performance Gear

The strength and lightweight properties of Kevlar used make it a valuable material in sports equipment. From tennis rackets to bicycle tires, Kevlar used is used to enhance performance and durability. Its ability to absorb vibration and withstand high stress makes it ideal for use in equipment that is subjected to repeated impacts and stresses.

Tennis Rackets and Other Sporting Goods

Tennis rackets often incorporate Kevlar used to increase their stiffness and power. The addition of Kevlar used helps to reduce vibration and improve control, allowing players to hit the ball with more force and accuracy. Other sporting goods, such as hockey sticks and skis, also use Kevlar used to enhance their performance and durability.

Bicycle Tires and Components

Bicycle tires reinforced with Kevlar used are more resistant to punctures and cuts, making them ideal for use in challenging conditions. Kevlar used is also used in bicycle frames and other components to reduce weight and improve strength. The use of Kevlar used in bicycles contributes to improved performance and reliability.

Other Applications of Kevlar

Beyond the applications discussed above, Kevlar used finds its way into a variety of other industries and products. Fiber optic cables, for example, use Kevlar used to provide strength and protect the delicate glass fibers from damage. Loudspeakers may utilize Kevlar used in the cone material for its stiffness and ability to reproduce sound accurately. Even medical implants and prosthetic devices can incorporate Kevlar used for its biocompatibility and strength.

The Future of Kevlar Used

The future of Kevlar used looks promising, with ongoing research and development focused on improving its properties and expanding its applications. Scientists are exploring ways to enhance its strength, heat resistance, and flexibility. New applications are constantly being discovered, driven by the increasing demand for lightweight, high-performance materials. As technology advances, Kevlar used will likely continue to play a vital role in shaping the future of various industries, ensuring greater safety, improved performance, and enhanced innovation. The versatility of Kevlar used guarantees its continued relevance in an ever-evolving world.

Conclusion

In conclusion, Kevlar used is a remarkable material that has transformed numerous industries with its exceptional strength, lightweight properties, and resistance to heat and chemicals. From personal protective equipment to aerospace engineering, Kevlar used has proven to be an invaluable asset, enhancing safety, performance, and innovation. As research and development continue, the future of Kevlar used looks bright, with the potential for even more groundbreaking applications in the years to come.