Kevlar Used: Exploring the Diverse Applications of This Revolutionary Material

Kevlar, a name synonymous with strength and resilience, is a para-aramid synthetic fiber renowned for its exceptional tensile strength-to-weight ratio. Discovered by Stephanie Kwolek at DuPont in 1965 and first commercially used in the early 1970s, Kevlar has since revolutionized numerous industries, offering unparalleled protection and performance. This article delves into the wide array of applications where Kevlar is used, highlighting its unique properties and impact across various sectors. The widespread use of Kevlar is a testament to its versatility and reliability.

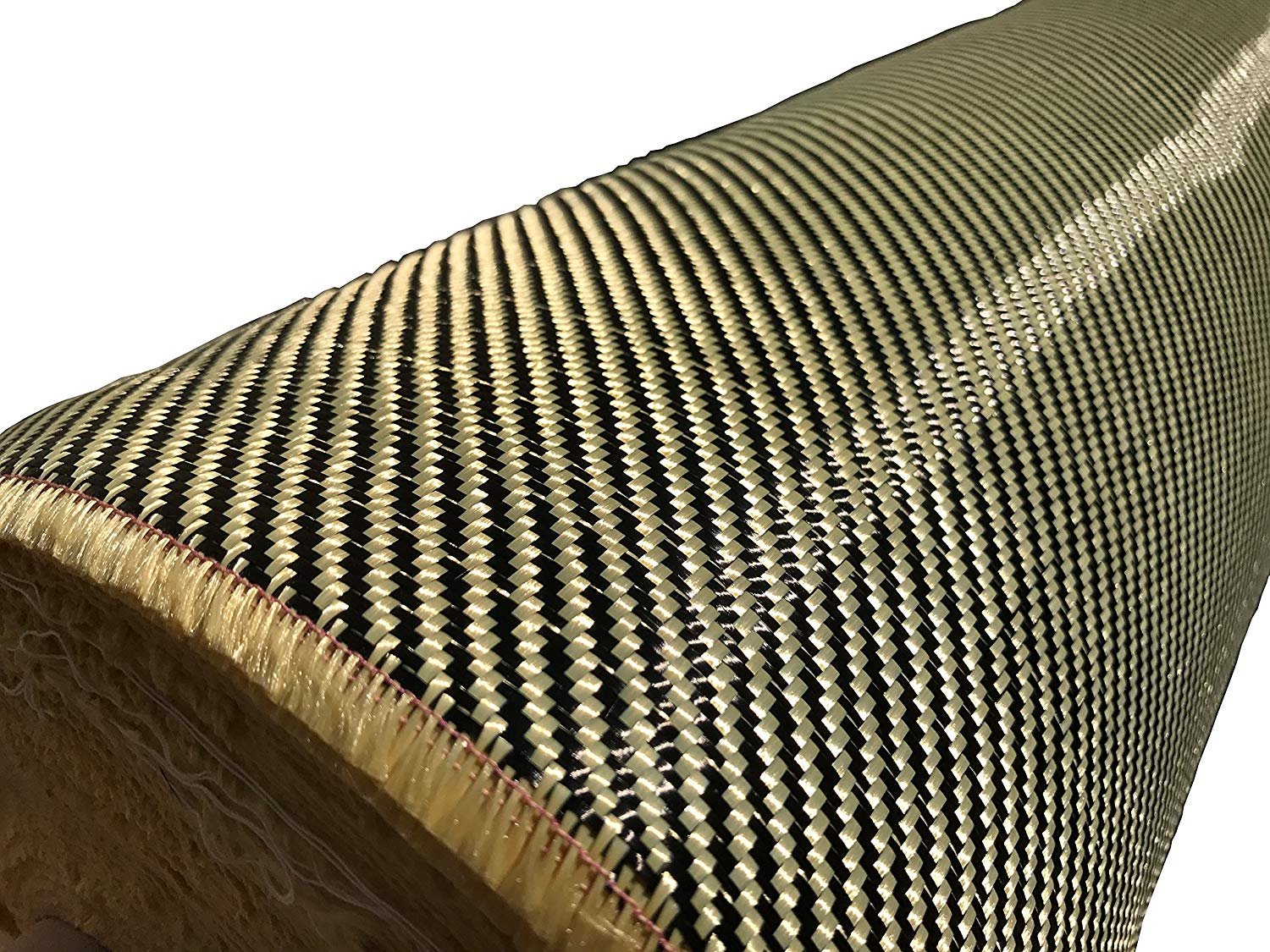

The Science Behind Kevlar’s Strength

To understand why Kevlar is so widely used, it’s crucial to grasp the science behind its strength. The polymer chains in Kevlar are highly oriented and tightly packed, creating a structure that resists stretching and deformation. This unique molecular arrangement allows Kevlar to absorb and dissipate energy, making it incredibly resistant to impact and abrasion. Its high tensile strength, approximately five times stronger than steel on an equal weight basis, makes it an ideal material for applications requiring extreme durability. Furthermore, Kevlar is inherently flame-resistant and can withstand temperatures up to 400 degrees Celsius (752 degrees Fahrenheit).

Protection and Safety: Where Kevlar Shines

Perhaps the most well-known application of Kevlar is in protective gear. Its ability to stop bullets and other projectiles makes it a critical component in body armor, helmets, and other protective equipment for law enforcement, military personnel, and security professionals. The use of Kevlar in these applications has undoubtedly saved countless lives. Beyond personal protection, Kevlar is also used in vehicle armor, reinforcing the chassis and panels of cars, trucks, and armored vehicles to protect occupants from ballistic threats. This is where Kevlar is especially important.

Body Armor and Ballistic Protection

Kevlar‘s use in body armor is a cornerstone of modern personal protection. Its layered construction effectively absorbs and disperses the energy of a bullet or projectile, preventing penetration and minimizing trauma to the wearer. Different grades and weaves of Kevlar are used to meet varying levels of ballistic protection, from stopping handgun rounds to resisting rifle fire. The evolution of Kevlar technology has led to lighter and more comfortable body armor, improving wearability and mobility for those who rely on it. [See also: The Future of Body Armor Materials]

Vehicle Armor

Beyond personal protection, Kevlar is used to reinforce vehicles, providing an added layer of security against ballistic threats. Kevlar panels are integrated into the body of vehicles, providing a lightweight yet robust defense against bullets and shrapnel. This application is particularly important for military vehicles, law enforcement cruisers, and armored transport vehicles, ensuring the safety of personnel in high-risk environments.

Industrial Applications: Harnessing Kevlar’s Durability

The exceptional strength and durability of Kevlar make it invaluable in a wide range of industrial applications. From reinforcing tires and cables to protecting workers in hazardous environments, Kevlar plays a crucial role in enhancing safety and performance across various industries.

Tires and Rubber Reinforcement

Kevlar is commonly used to reinforce tires, increasing their strength, durability, and resistance to punctures and blowouts. The addition of Kevlar fibers to the rubber compound enhances the tire’s structural integrity, allowing it to withstand higher pressures and temperatures. This is particularly important for high-performance tires used in racing and other demanding applications. Furthermore, Kevlar reinforcement improves the tire’s resistance to wear and tear, extending its lifespan and reducing the risk of accidents. [See also: Tire Technology Advancements]

Ropes and Cables

The high tensile strength of Kevlar makes it an ideal material for ropes and cables used in demanding applications such as mooring lines, suspension bridges, and lifting equipment. Kevlar ropes are significantly stronger and lighter than steel cables of comparable size, making them easier to handle and deploy. Their resistance to abrasion and corrosion also ensures long-term reliability in harsh environments. The use of Kevlar in these applications enhances safety and efficiency, reducing the risk of failure and minimizing maintenance requirements.

Protective Clothing for Industrial Workers

Kevlar is used in protective clothing for industrial workers who face risks such as cuts, abrasions, and heat exposure. Kevlar-reinforced gloves, sleeves, and aprons provide a durable barrier against these hazards, minimizing the risk of injury. The flame-resistant properties of Kevlar also make it suitable for protective clothing used in welding, firefighting, and other high-temperature environments. The use of Kevlar in industrial protective clothing enhances worker safety and reduces the incidence of workplace accidents.

Beyond Protection: Unexpected Uses of Kevlar

The versatility of Kevlar extends beyond protection and industrial applications, finding its way into a variety of unexpected products and industries. From musical instruments to sporting goods, Kevlar‘s unique properties contribute to enhanced performance and durability.

Musical Instruments

Kevlar is sometimes used in the construction of musical instruments, particularly drumheads and speaker cones. Its high tensile strength and stiffness contribute to improved sound quality and durability. Kevlar drumheads offer a crisp, responsive sound and are less prone to damage than traditional drumheads. Similarly, Kevlar speaker cones can handle higher power levels and produce a cleaner, more accurate sound. The use of Kevlar in musical instruments is a testament to its versatility and ability to enhance performance in unexpected applications.

Sporting Goods

Kevlar is used in a variety of sporting goods, including bicycle tires, tennis rackets, and hockey sticks. In bicycle tires, Kevlar reinforcement provides increased puncture resistance and improved rolling efficiency. In tennis rackets, Kevlar fibers enhance the frame’s stiffness and power. In hockey sticks, Kevlar reinforcement increases durability and reduces the risk of breakage. The use of Kevlar in sporting goods helps athletes achieve peak performance and minimizes equipment failures.

Aerospace Applications

The lightweight and high-strength properties of Kevlar make it suitable for certain aerospace applications. It is used in composite materials for aircraft components, offering weight savings and improved structural integrity. Kevlar is also used in the construction of spacecraft heat shields, providing thermal protection during atmospheric re-entry. While carbon fiber is more prevalent in aerospace due to its superior stiffness-to-weight ratio, Kevlar still finds niche applications where its unique properties are beneficial.

The Future of Kevlar: Innovation and Sustainability

As technology advances, ongoing research and development efforts are focused on improving the properties and sustainability of Kevlar. Innovations include developing new Kevlar blends with enhanced performance characteristics, as well as exploring more environmentally friendly manufacturing processes. The future of Kevlar lies in pushing the boundaries of its capabilities and minimizing its environmental impact. [See also: Sustainable Materials in the 21st Century]

In conclusion, Kevlar is a remarkable material with a wide range of applications, from protecting lives in body armor to enhancing performance in sporting goods. Its unique combination of strength, durability, and versatility has made it an indispensable component in numerous industries. As technology continues to evolve, Kevlar will undoubtedly play an even greater role in shaping the future of protection, performance, and innovation. The applications where Kevlar is used continue to grow, demonstrating its enduring value. The impact of Kevlar is undeniable.