Kevlar Used: Exploring the Diverse Applications of This Revolutionary Material

Kevlar, a name synonymous with strength and resilience, has permeated countless industries since its invention in 1965 by Stephanie Kwolek at DuPont. This para-aramid synthetic fiber, renowned for its high tensile strength-to-weight ratio, is approximately five times stronger than steel on an equal weight basis. The wide range of kevlar used across various sectors stems from its exceptional properties, including heat resistance, chemical resistance, and low weight. This article delves into the diverse applications of kevlar used, exploring its impact on safety, technology, and everyday life.

The Origins and Properties of Kevlar

Developed by DuPont, kevlar‘s creation was a significant breakthrough in material science. Its molecular structure consists of long, rigid molecules oriented along the fiber axis, contributing to its exceptional strength and stiffness. This unique structure is achieved through a process called spinning, where the polymer solution is extruded through a spinneret and then subjected to stretching and heat treatment. This process aligns the molecules, resulting in a highly ordered crystalline structure that imparts kevlar‘s characteristic properties.

Beyond its tensile strength, kevlar used exhibits remarkable resistance to heat and flame. It decomposes at temperatures around 400°C (752°F), making it suitable for applications requiring thermal protection. Furthermore, kevlar demonstrates good resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. However, prolonged exposure to strong acids or bases can degrade the material. Its lightweight nature compared to traditional materials like steel is another key advantage, leading to weight savings in various applications.

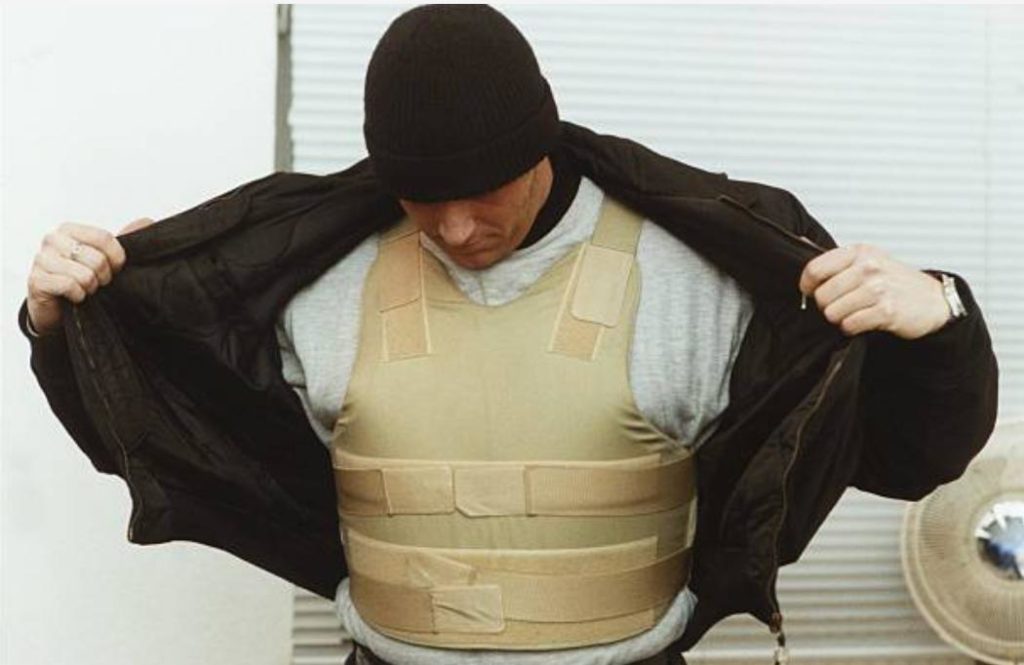

Kevlar Used in Personal Protective Equipment

One of the most well-known applications of kevlar used is in personal protective equipment (PPE), particularly in bulletproof vests and body armor. Its high tensile strength and ability to absorb impact energy make it an ideal material for deflecting bullets and other projectiles. Kevlar vests are widely used by law enforcement officers, military personnel, and security guards, providing crucial protection against ballistic threats. The effectiveness of kevlar used in these applications has saved countless lives, solidifying its reputation as a life-saving material.

Beyond body armor, kevlar used in gloves, sleeves, and other protective clothing for workers in industries such as construction, manufacturing, and mining. These garments protect against cuts, abrasions, and punctures, reducing the risk of workplace injuries. The lightweight and flexible nature of kevlar allows for comfortable wear, even during strenuous activities. Firefighters also rely on kevlar used in their protective gear, including coats, pants, and helmets, to shield them from the intense heat and flames encountered during firefighting operations. [See also: Fire Resistant Clothing Materials]

Kevlar Used in the Automotive Industry

The automotive industry has embraced kevlar used in various components to enhance safety, performance, and fuel efficiency. Kevlar reinforced tires offer increased puncture resistance and improved handling, contributing to safer driving experiences. The use of kevlar in brake pads enhances their durability and braking performance, reducing the risk of brake fade and improving stopping distances. Furthermore, kevlar used in clutch linings increases their lifespan and improves power transfer efficiency.

The lightweight properties of kevlar used also contribute to improved fuel efficiency in vehicles. By replacing heavier materials with kevlar composites in body panels and structural components, manufacturers can reduce the overall weight of the vehicle, leading to better fuel economy and reduced emissions. Additionally, kevlar used in racing cars enhances their safety and performance. Its high strength-to-weight ratio allows for the construction of lightweight yet robust chassis and body panels, improving handling and acceleration. The impact resistance of kevlar also provides crucial protection for drivers in the event of a crash.

Kevlar Used in Aerospace Applications

The aerospace industry leverages the exceptional properties of kevlar used in a wide range of applications, including aircraft components, spacecraft structures, and protective equipment. Its lightweight nature and high strength-to-weight ratio are particularly advantageous in aerospace applications, where weight reduction is crucial for fuel efficiency and performance. Kevlar composites are used in aircraft fuselage panels, wing structures, and interior components, reducing the overall weight of the aircraft and improving its fuel efficiency. [See also: Aerospace Composites Market Trends]

Kevlar used in spacecraft structures provides protection against micrometeoroids and orbital debris, which can pose a significant threat to spacecraft in orbit. Its ability to absorb impact energy and prevent penetration makes it an effective shield against these hazards. Astronauts also rely on kevlar used in their spacesuits to provide protection against extreme temperatures, radiation, and micrometeoroids. The durability and reliability of kevlar are essential for ensuring the safety and success of space missions.

Kevlar Used in Marine Applications

The marine industry utilizes kevlar used in boat hulls, sails, and ropes due to its strength, durability, and resistance to saltwater corrosion. Kevlar reinforced boat hulls offer increased impact resistance and reduced weight, improving the vessel’s performance and fuel efficiency. The use of kevlar in sails enhances their strength and durability, allowing them to withstand high winds and harsh marine conditions. Kevlar ropes are stronger and lighter than traditional ropes, making them ideal for mooring, towing, and other marine applications.

The resistance of kevlar used to saltwater corrosion is a significant advantage in marine environments. Unlike steel, kevlar does not rust or corrode when exposed to saltwater, making it a long-lasting and reliable material for marine applications. Its use in underwater cables and pipelines provides protection against damage from marine organisms and environmental factors. The versatility of kevlar used makes it a valuable material for a wide range of marine applications, from recreational boating to commercial shipping.

Other Notable Applications of Kevlar Used

Beyond the applications mentioned above, kevlar used in a variety of other industries and products. In sports equipment, kevlar reinforced helmets, protective gear, and sporting goods offer increased protection and performance. Musical instruments, such as drumheads and speaker cones, utilize kevlar to enhance their sound quality and durability. In the telecommunications industry, kevlar reinforced cables provide increased strength and protection against damage. Its use in medical implants and prosthetics offers biocompatibility and durability. The versatility and exceptional properties of kevlar used continue to drive innovation and expand its applications across diverse fields.

The enduring appeal of kevlar lies in its ability to provide a unique combination of strength, lightweight, and resistance to harsh conditions. From protecting law enforcement officers to enhancing the performance of race cars, kevlar used has revolutionized numerous industries and improved countless lives. As material science continues to advance, we can expect to see even more innovative applications of this remarkable material in the years to come. The future of kevlar used is bright, promising further advancements in safety, technology, and everyday life. The continuous research and development efforts focused on kevlar are paving the way for new and improved formulations, expanding its potential and solidifying its position as a leading material in the 21st century.

The Future of Kevlar and its Applications

Research and development continue to explore new formulations and applications for kevlar. Scientists are working on improving its resistance to UV degradation and developing more flexible and comfortable kevlar-based materials. Nanotechnology is also playing a role in enhancing the properties of kevlar, leading to even stronger and more durable materials. The future of kevlar used is promising, with potential applications in areas such as advanced composites, energy storage, and biomedical engineering. As technology evolves, kevlar will undoubtedly continue to play a vital role in shaping the future of materials science and engineering.