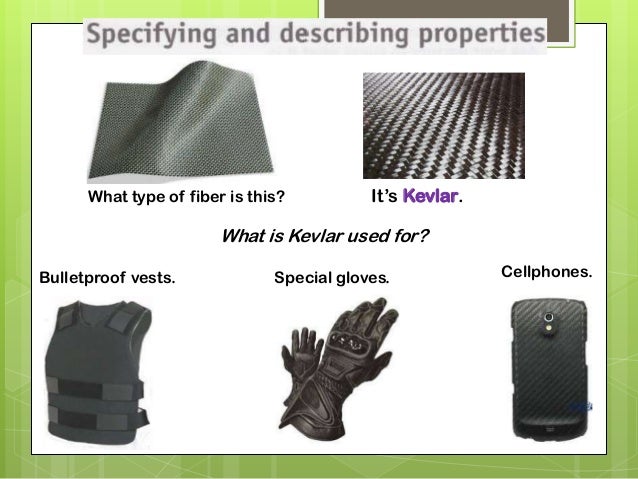

Kevlar Used: Exploring the Diverse Applications of This Revolutionary Material

Kevlar, a name synonymous with strength and resilience, has revolutionized numerous industries since its invention in 1965 by Stephanie Kwolek at DuPont. This para-aramid synthetic fiber, known for its high tensile strength-to-weight ratio, is approximately five times stronger than steel on an equal weight basis. The unique properties of Kevlar used have led to its adoption in a wide array of applications, ranging from personal protective equipment to advanced aerospace components. This article delves into the diverse ways Kevlar used impacts our lives, exploring its history, properties, and specific applications across various sectors.

The History and Development of Kevlar

The story of Kevlar used begins with Stephanie Kwolek’s groundbreaking work at DuPont. While searching for a lightweight yet strong fiber to replace steel in tires, Kwolek stumbled upon a solution of poly-paraphenylene terephthalamide. Initially dismissed due to its cloudy and thin appearance, this solution was spun into fibers that exhibited unprecedented strength and stiffness. DuPont recognized the potential of this new material and patented it in 1966, officially launching Kevlar used into the world in 1971.

Understanding the Properties of Kevlar

The exceptional performance of Kevlar used stems from its unique molecular structure. The long, rigid polymer chains are highly oriented, leading to strong intermolecular bonding. This arrangement provides Kevlar used with its remarkable tensile strength, high modulus of elasticity, and resistance to heat and chemicals. Furthermore, Kevlar used is lightweight, making it an ideal material for applications where weight reduction is crucial. It also demonstrates excellent cut and puncture resistance, contributing to its popularity in protective gear.

Applications in Personal Protective Equipment

One of the most well-known applications of Kevlar used is in personal protective equipment, particularly bulletproof vests. The high tensile strength of Kevlar used allows it to absorb and dissipate the energy of a projectile, preventing penetration and minimizing injury. Law enforcement officers, military personnel, and security guards rely on Kevlar used in body armor to protect themselves from ballistic threats. Beyond bulletproof vests, Kevlar used is also found in cut-resistant gloves, helmets, and other protective gear used in various industries, including construction, manufacturing, and law enforcement. The material’s ability to withstand extreme conditions makes it a critical component in ensuring workplace safety.

Kevlar Used in the Automotive Industry

The automotive industry leverages the unique properties of Kevlar used in several ways. High-performance tires often incorporate Kevlar used in their construction to enhance strength, durability, and resistance to punctures. The lightweight nature of Kevlar used also contributes to improved fuel efficiency. Furthermore, Kevlar used can be found in brake pads, clutch linings, and other components where high strength and heat resistance are required. Race cars frequently utilize Kevlar used in body panels and other structural elements to reduce weight and improve performance.

Aerospace Applications of Kevlar

The aerospace industry benefits significantly from the use of Kevlar used. Its lightweight and high-strength properties make it an ideal material for aircraft components, including fuselage panels, rotor blades, and engine housings. Using Kevlar used in aircraft construction reduces weight, leading to improved fuel efficiency and increased payload capacity. In spacecraft, Kevlar used provides protection against micrometeoroids and orbital debris. Its resistance to extreme temperatures and radiation also makes it suitable for use in space suits and other equipment used by astronauts.

Kevlar in Marine Applications

Kevlar used is also prevalent in marine applications. Its resistance to saltwater and its high strength make it an excellent material for boat hulls, sails, and ropes. Kevlar used reinforced hulls are lighter and stronger than traditional fiberglass hulls, resulting in improved performance and fuel efficiency. In sailing, Kevlar used is used in high-performance sails to provide superior strength and shape retention. Ropes made from Kevlar used are stronger and lighter than steel cables, making them ideal for use in mooring lines, towing cables, and other marine applications. [See also: Marine Composites: A Comprehensive Guide]

Sports Equipment Utilizing Kevlar

The sports industry has embraced Kevlar used for its strength and lightweight properties. It is commonly found in protective gear such as helmets, pads, and gloves used in various sports, including cycling, hockey, and motor racing. Kevlar used reinforced helmets provide superior impact protection, reducing the risk of head injuries. In cycling, Kevlar used tires offer enhanced puncture resistance and improved performance. Racket sports, such as tennis and badminton, also utilize Kevlar used in racket frames to enhance strength and stiffness. The incorporation of Kevlar used in sports equipment helps athletes perform at their best while minimizing the risk of injury.

Industrial Applications of Kevlar

Beyond the applications mentioned above, Kevlar used finds use in various industrial settings. It is used in fiber optic cables to provide strength and protection to the delicate glass fibers. Kevlar used reinforced conveyor belts are used in mining and manufacturing industries to transport heavy materials. The chemical resistance of Kevlar used makes it suitable for use in chemical processing plants, where it is used in protective clothing and equipment. Its high strength and durability make it a valuable material in many demanding industrial applications.

The Future of Kevlar Used

The future of Kevlar used looks promising, with ongoing research and development efforts focused on improving its properties and expanding its applications. Researchers are exploring new ways to enhance the strength, flexibility, and resistance to degradation of Kevlar used. Nanotechnology is being used to create Kevlar used composites with enhanced properties. Furthermore, efforts are underway to develop more sustainable and environmentally friendly methods for producing Kevlar used. As technology advances, we can expect to see Kevlar used in even more innovative and groundbreaking applications. [See also: Sustainable Materials in Manufacturing]

Conclusion

From protecting law enforcement officers to enabling advancements in aerospace, Kevlar used has proven to be a revolutionary material with a wide range of applications. Its unique combination of strength, lightweight, and resistance to extreme conditions has made it indispensable in numerous industries. As research and development continue, we can expect to see even more innovative uses for Kevlar used in the future, further solidifying its position as a cornerstone material in modern technology. The legacy of Stephanie Kwolek’s discovery continues to impact our world in profound ways, demonstrating the power of scientific innovation to transform industries and improve lives. The versatility of Kevlar used ensures its continued relevance in a rapidly evolving technological landscape.