Kevlar Used: Exploring the Diverse Applications of this Revolutionary Material

Kevlar, a name synonymous with strength and resilience, has revolutionized numerous industries since its invention in 1965 by Stephanie Kwolek at DuPont. This para-aramid synthetic fiber is renowned for its high tensile strength-to-weight ratio, making it five times stronger than steel on an equal weight basis. The diverse ways Kevlar used spans from life-saving body armor to high-performance sporting equipment. This article delves into the fascinating world of Kevlar used, examining its properties, manufacturing process, and a wide array of its applications across various sectors.

Understanding Kevlar’s Unique Properties

Before exploring how Kevlar used, it’s crucial to understand the material’s remarkable properties. Kevlar’s exceptional strength stems from its molecular structure. It consists of long, rigid polymer chains that are highly oriented and tightly packed. These chains are held together by strong hydrogen bonds, which provide the material with its exceptional resistance to heat, chemicals, and impact.

- High Tensile Strength: Kevlar’s most notable property is its ability to withstand immense tensile forces without breaking.

- Heat Resistance: Kevlar can withstand temperatures up to 400°C (752°F) for short periods, making it suitable for high-temperature applications.

- Chemical Resistance: Kevlar is resistant to a wide range of chemicals, including acids, bases, and solvents.

- Lightweight: Despite its strength, Kevlar is remarkably lightweight, making it ideal for applications where weight is a critical factor.

- Cut and Puncture Resistance: The tightly woven structure of Kevlar fabrics provides excellent resistance to cuts and punctures.

The Manufacturing Process of Kevlar

The manufacturing of Kevlar is a complex process involving the polymerization of para-phenylenediamine and terephthaloyl chloride. This reaction produces a liquid crystalline solution that is then spun into fibers. The fibers are then drawn and heat-treated to further enhance their strength and orientation. The specific manufacturing process can vary depending on the desired properties of the finished product. Quality control is paramount to ensure the Kevlar used meets stringent standards.

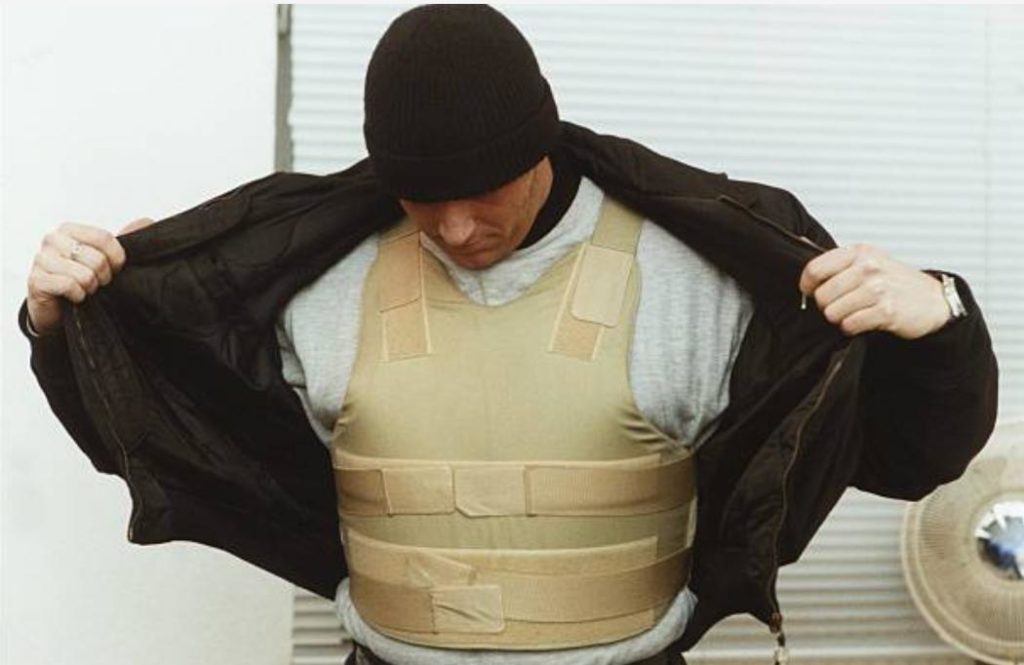

Life-Saving Applications: Body Armor and Ballistic Protection

Perhaps the most well-known application of Kevlar used is in body armor. Law enforcement officers, military personnel, and security guards rely on Kevlar vests to protect themselves from ballistic threats. Kevlar’s ability to absorb and dissipate the energy of a bullet or shrapnel significantly reduces the risk of serious injury or death. The material’s lightweight nature allows for comfortable wear, even during extended periods of use. Beyond vests, Kevlar used in helmets, vehicle armor, and even bomb disposal suits, showcasing its vital role in protecting lives.

Industrial Applications: Reinforcement and Protection

Beyond personal protection, Kevlar used extensively in various industrial applications. Its strength and durability make it an ideal reinforcement material for:

- Tires: Kevlar belts are used in tires to improve their strength, durability, and resistance to punctures.

- Hoses and Cables: Kevlar reinforcement enhances the pressure resistance and lifespan of hoses and cables used in demanding environments.

- Fiber Optic Cables: Kevlar used to protect delicate fiber optic cables from damage during installation and use.

- Construction Materials: Kevlar fibers can be incorporated into concrete and other construction materials to improve their strength and resistance to cracking.

The use of Kevlar used in these applications contributes to enhanced safety, performance, and longevity of industrial equipment and infrastructure. [See also: High-Performance Materials in Construction]

Sporting Goods: Enhancing Performance and Safety

The lightweight and high-strength properties of Kevlar used make it a valuable material in the sporting goods industry. It is employed in a wide range of applications, including:

- Bicycle Tires: Kevlar layers in bicycle tires provide puncture resistance and improve rolling efficiency.

- Racing Sails: Kevlar fabrics are used in high-performance racing sails to provide strength and stability.

- Protective Gear: Kevlar used in gloves, pads, and other protective gear for sports like motorcycling, skiing, and snowboarding to protect against abrasion and impact.

- Tennis Racquets: Some tennis racquets incorporate Kevlar to enhance their stiffness and power.

By incorporating Kevlar used into sporting goods, manufacturers can improve performance, enhance safety, and provide athletes with a competitive edge.

Aerospace Applications: Lightweight Strength for Flight

The aerospace industry relies heavily on lightweight, high-strength materials, and Kevlar used fits the bill perfectly. It finds applications in:

- Aircraft Components: Kevlar composites are used in aircraft fuselages, wings, and other components to reduce weight and improve fuel efficiency.

- Helicopter Blades: Kevlar reinforcement enhances the strength and durability of helicopter blades.

- Rocket Motor Casings: Kevlar’s high tensile strength and heat resistance make it suitable for rocket motor casings.

The use of Kevlar used in aerospace applications contributes to improved aircraft performance, safety, and fuel efficiency. [See also: Advanced Composites in Aerospace Engineering]

Marine Applications: Resistance to the Elements

The marine environment presents unique challenges for materials, including exposure to saltwater, UV radiation, and harsh weather conditions. Kevlar used‘s resistance to these elements makes it a valuable material for marine applications, such as:

- Boat Hulls: Kevlar composites are used in boat hulls to provide strength, durability, and resistance to impact.

- Ropes and Cables: Kevlar ropes and cables are used in mooring lines, rigging, and other marine applications where high strength and low stretch are required.

- Sails: As mentioned earlier, Kevlar used in high-performance sails for its strength and stability.

The use of Kevlar used in marine applications contributes to improved boat performance, safety, and longevity.

Other Notable Applications

The versatility of Kevlar used extends beyond the applications mentioned above. Other notable uses include:

- Musical Instruments: Kevlar fibers are used in some musical instrument components, such as drumheads and speaker cones, to enhance their sound quality and durability.

- Medical Implants: Kevlar’s biocompatibility and strength make it suitable for certain medical implant applications.

- Geotextiles: Kevlar fabrics are used as geotextiles to reinforce soil and prevent erosion.

The Future of Kevlar Used

The development of new and improved Kevlar variants continues to drive innovation across various industries. Researchers are exploring new ways to enhance its properties, reduce its cost, and expand its applications. The future of Kevlar used is bright, with potential for further advancements in areas such as nanotechnology and bio-based Kevlar alternatives. As technology advances, the range of Kevlar used will undoubtedly expand. [See also: The Future of Materials Science]

Conclusion

Kevlar used has proven to be a revolutionary material with a wide range of applications across diverse industries. Its exceptional strength, lightweight nature, and resistance to heat, chemicals, and impact make it an invaluable asset in life-saving body armor, high-performance sporting goods, aerospace components, marine applications, and numerous other fields. As research and development continue, the future of Kevlar used holds immense potential for further innovation and advancements.