Kevlar Used: Exploring the Diverse Applications of This High-Performance Material

Kevlar, a name synonymous with strength and resilience, has permeated various industries since its invention in 1965 by Stephanie Kwolek at DuPont. This para-aramid synthetic fiber boasts exceptional tensile strength-to-weight ratio, making it an indispensable material in applications ranging from body armor to aerospace engineering. Understanding where and how Kevlar used is crucial to appreciating its impact on modern technology and safety.

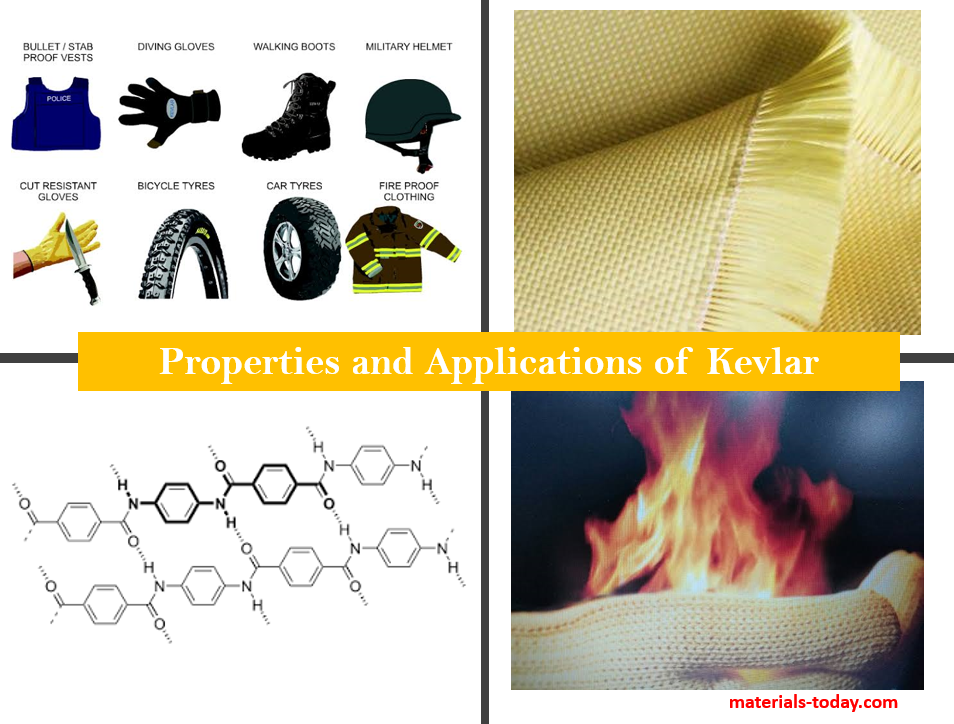

The Science Behind Kevlar’s Strength

The remarkable properties of Kevlar stem from its molecular structure. It consists of long, rigid molecules oriented in a highly ordered manner. These molecules align themselves parallel to the fiber axis, enabling strong intermolecular interactions through hydrogen bonds. This arrangement results in a material that is incredibly resistant to stretching and deformation. The high tensile strength means Kevlar can withstand significant pulling forces before breaking, far exceeding that of steel on a weight-for-weight basis.

Kevlar Used in Personal Protective Equipment

Perhaps the most well-known application of Kevlar is in personal protective equipment, particularly body armor. Bulletproof vests and helmets incorporating Kevlar layers are widely used by law enforcement, military personnel, and security professionals. The fiber’s ability to absorb and dissipate the energy of a projectile, such as a bullet or shrapnel, significantly reduces the risk of injury or death. Multiple layers of tightly woven Kevlar fabric are typically used to create this protection. The Kevlar used in these applications is often treated with special coatings to enhance its resistance to water and other environmental factors.

Beyond body armor, Kevlar used in protective gloves for industries that handle sharp objects, such as glass manufacturing and metalworking. These gloves offer excellent cut resistance, safeguarding workers from potential injuries.

Aerospace and Automotive Applications

The aerospace industry leverages the lightweight and high-strength properties of Kevlar in various components. Kevlar used in aircraft panels, rotor blades, and even tires. Its resistance to heat and impact makes it an ideal material for demanding environments. The reduction in weight achieved by using Kevlar contributes to improved fuel efficiency and performance.

In the automotive industry, Kevlar used in brake pads, clutch linings, and tire reinforcement. The high heat resistance of Kevlar ensures consistent braking performance even under extreme conditions. In tires, Kevlar enhances puncture resistance and overall durability, improving safety and extending the lifespan of the tire. [See also: Automotive Composite Materials: A Comprehensive Guide]

Marine and Sporting Goods

The marine industry utilizes Kevlar in boat hulls, sails, and ropes. The material’s resistance to saltwater corrosion and its high strength-to-weight ratio make it an excellent choice for marine applications. Kevlar used in racing yachts to improve performance and durability. The strength and lightweight nature of Kevlar allows for the construction of lighter, faster, and more durable vessels.

Sporting goods also benefit from the properties of Kevlar. Kevlar used in bicycle tires to enhance puncture resistance, in tennis rackets to improve frame stiffness, and in protective gear for various sports, such as hockey and snowboarding. The use of Kevlar in these applications enhances performance and safety for athletes.

Industrial Applications of Kevlar

Industrial applications of Kevlar are numerous and diverse. It is used in fiber optic cables to provide strength and protection to the delicate glass fibers. Kevlar used in high-pressure hoses and conveyor belts due to its exceptional tensile strength and resistance to abrasion. The material’s durability and resistance to harsh environments make it a reliable choice for demanding industrial applications.

Specific Examples of Kevlar Used

- Fiber Optic Cables: Kevlar strands surround the delicate glass fibers, protecting them from damage during installation and use.

- High-Pressure Hoses: Kevlar reinforcement allows hoses to withstand extreme pressures without bursting.

- Conveyor Belts: Kevlar improves the strength and durability of conveyor belts, extending their lifespan and reducing downtime.

The Future of Kevlar and Related Materials

Research and development efforts continue to explore new and innovative applications for Kevlar and related materials. Scientists are working on improving the material’s properties, such as its resistance to compression and its ability to be processed into different forms. [See also: The Future of Advanced Materials in Manufacturing] The development of new Kevlar composites and hybrid materials is opening up new possibilities for its use in a wider range of applications.

One area of focus is on developing more sustainable and environmentally friendly alternatives to traditional Kevlar. Researchers are exploring bio-based aramid fibers and recycling methods to reduce the environmental impact of Kevlar production and disposal. The future of Kevlar will likely involve a greater emphasis on sustainability and the development of materials with enhanced performance characteristics.

Considerations When Using Kevlar

While Kevlar is a remarkable material, it’s important to understand its limitations. Kevlar is susceptible to degradation from ultraviolet (UV) light and prolonged exposure to moisture. Therefore, Kevlar products often require special coatings or treatments to protect them from these environmental factors. Additionally, Kevlar is relatively expensive compared to other materials, which can limit its use in certain applications. Understanding these considerations is crucial for selecting the right material for a specific application and ensuring its long-term performance. The specific Kevlar used should always be appropriate for the intended purpose.

Conclusion: The Enduring Legacy of Kevlar

From its humble beginnings in a DuPont laboratory to its widespread use in countless applications, Kevlar has revolutionized the way we protect ourselves and build things. Its exceptional strength, lightweight, and resistance to heat and chemicals have made it an indispensable material in a wide range of industries. As research and development continue to push the boundaries of materials science, Kevlar will undoubtedly continue to play a vital role in shaping the future of technology and safety. The versatility of Kevlar used ensures its continued relevance in a constantly evolving world.