EPS Surfboards: Understanding the Performance and Durability of Expanded Polystyrene

In the ever-evolving world of surfing, innovation in surfboard construction is constant. Among the various materials used, Expanded Polystyrene, commonly known as EPS surf, has gained significant traction. This article delves into the properties, performance characteristics, and considerations surrounding EPS surfboards, providing a comprehensive overview for surfers of all levels.

What is EPS?

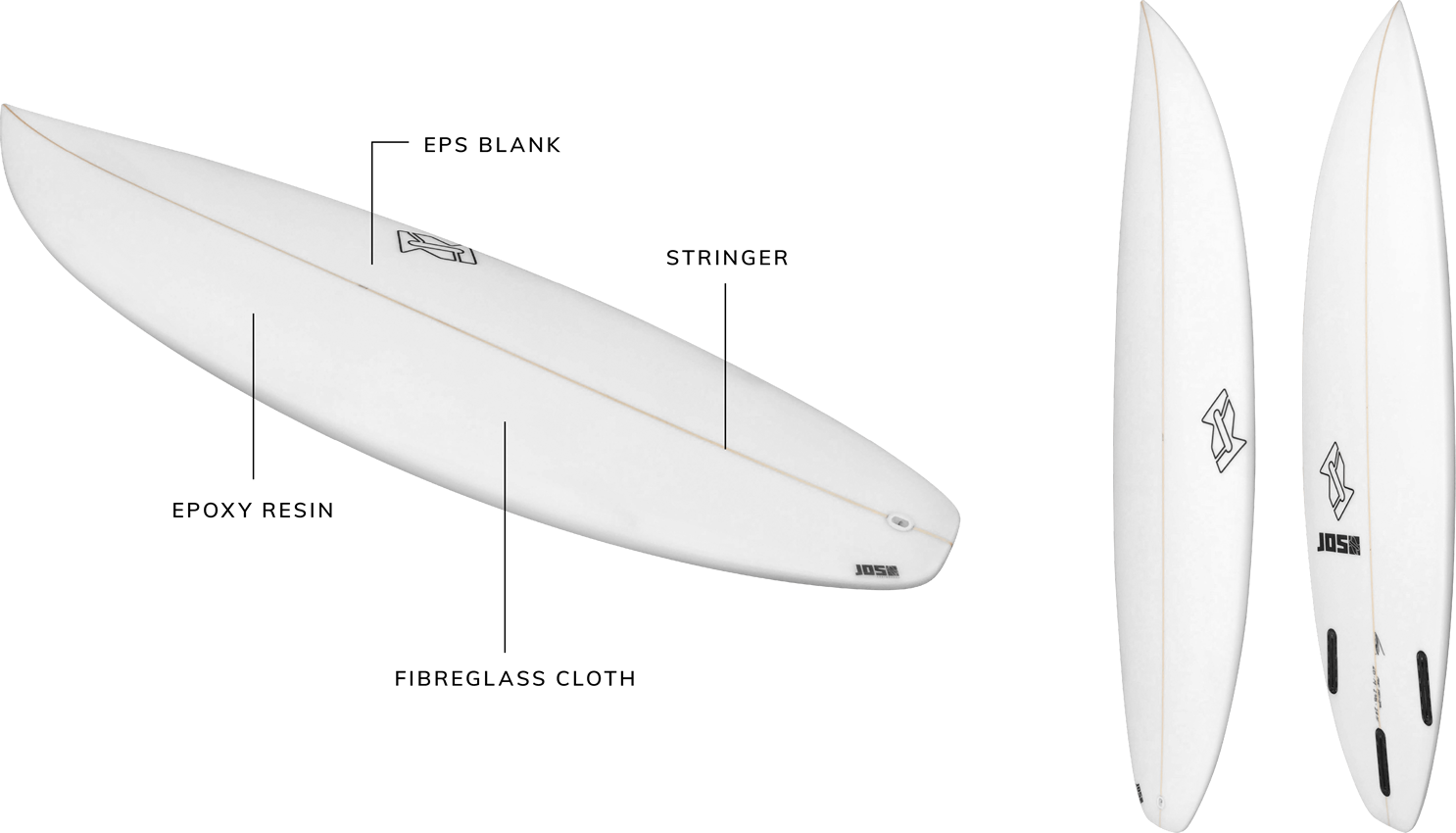

Expanded Polystyrene (EPS) is a closed-cell thermoplastic foam known for its lightweight nature, excellent insulation properties, and buoyancy. It’s created by expanding polystyrene beads using steam, resulting in a rigid foam structure. In the context of EPS surfboards, EPS foam is typically used as the core material, which is then glassed with epoxy resin and fiberglass cloth.

The Rise of EPS Surfboards

EPS surfboards have become increasingly popular for several reasons. Their inherent buoyancy makes them easier to paddle and catch waves, a significant advantage for beginners and those surfing in smaller conditions. The lightweight nature of EPS surf also contributes to a more responsive and lively feel on the wave, allowing for quicker turns and greater maneuverability. Furthermore, advancements in epoxy resin technology have mitigated some of the earlier durability concerns associated with EPS surfboards.

Performance Characteristics of EPS Surfboards

Buoyancy and Paddling

One of the most notable advantages of EPS surfboards is their superior buoyancy compared to traditional polyurethane (PU) boards. This increased buoyancy translates to easier paddling, allowing surfers to conserve energy and catch more waves. This is particularly beneficial in weaker surf conditions or for surfers who may not be as strong paddlers.

Responsiveness and Speed

The lightweight nature of EPS surf contributes to a more responsive and lively feel underfoot. EPS surfboards tend to accelerate quickly and maintain speed through flat sections. This responsiveness makes them ideal for performing quick turns and generating speed in smaller to medium-sized waves.

Flex and Drive

The flex characteristics of an EPS surfboard are largely determined by the type of epoxy resin and fiberglass cloth used in the lamination process. Generally, EPS surfboards tend to have a more lively and springy flex pattern compared to PU boards. This can translate to more pop and projection out of turns, but some surfers may find them less predictable in heavier conditions. The drive an EPS surf provides can be significantly impacted by the fin setup used; experimenting with different fin types can help tailor the board’s performance to your surfing style and the wave conditions.

Durability Considerations

Early EPS surfboards were often criticized for their lack of durability compared to PU boards. EPS foam is generally more susceptible to dings and pressure dents. However, advancements in epoxy resin technology and lamination techniques have significantly improved the durability of modern EPS surfboards. Using higher-density EPS foam and multiple layers of fiberglass cloth can create a more robust and durable board. Careful handling and proper care are still essential to prolong the lifespan of an EPS surfboard.

Epoxy vs. Polyester Resin

It’s crucial to note that EPS surfboards must be glassed with epoxy resin. Polyester resin, which is commonly used with PU boards, will dissolve EPS foam. Epoxy resin is stronger and more flexible than polyester resin, contributing to the overall performance and durability of the EPS surfboard. Epoxy also tends to be more environmentally friendly.

Types of EPS Foam Used in Surfboards

Not all EPS foam is created equal. Different densities and formulations are available, each offering unique properties for surfboard construction.

Standard EPS

Standard EPS is the most common type used in EPS surfboards. It offers a good balance of weight, buoyancy, and cost. However, it’s also the least durable option.

High-Density EPS

High-density EPS is more durable than standard EPS, offering increased resistance to dings and pressure dents. It’s often used in performance-oriented EPS surfboards where durability is a concern. While more durable, it does add slightly more weight to the board.

Fused Cell EPS

Fused cell EPS is a premium option known for its exceptional strength and water resistance. It’s created using a unique manufacturing process that fuses the EPS cells together, resulting in a more uniform and durable foam. This type of EPS surf core is often found in high-end EPS surfboards.

Choosing the Right EPS Surfboard

Selecting the right EPS surfboard depends on several factors, including your skill level, surfing style, and the type of waves you typically ride.

Skill Level

EPS surfboards are generally a good choice for beginners due to their increased buoyancy and paddling ease. Intermediate and advanced surfers can also benefit from the responsiveness and speed of EPS surfboards, particularly in smaller to medium-sized waves.

Wave Conditions

EPS surfboards excel in smaller to medium-sized waves. Their responsiveness and speed make them ideal for generating speed and performing quick turns. While they can be ridden in larger waves, some surfers may prefer the more predictable feel of a PU board in heavier conditions. However, advancements in EPS surf construction are making them more viable in a wider range of conditions.

Surfboard Design

The overall design of the EPS surfboard also plays a crucial role in its performance. Consider the board’s dimensions (length, width, thickness), rocker, and tail shape. A wider board with a flatter rocker will be more stable and easier to paddle, while a narrower board with more rocker will be more maneuverable. [See also: Surfboard Rocker Explained] The tail shape will also influence the board’s turning characteristics.

Caring for Your EPS Surfboard

Proper care is essential to prolong the lifespan of your EPS surfboard.

- Avoid excessive heat: Do not leave your surfboard in direct sunlight or in a hot car, as this can cause delamination.

- Protect from dings: Be careful when handling your surfboard to avoid dings and pressure dents. Use a surfboard bag for transport and storage.

- Repair dings promptly: Even small dings can allow water to penetrate the foam core, leading to further damage. Repair dings as soon as possible using epoxy resin.

- Rinse with fresh water: After each surf session, rinse your surfboard with fresh water to remove salt and sand.

The Future of EPS Surfboards

The future of EPS surfboards looks bright. Ongoing advancements in materials and construction techniques are constantly improving their performance, durability, and sustainability. As surfers continue to embrace the benefits of EPS surf, we can expect to see even more innovative and high-performance EPS surfboards in the years to come. [See also: Sustainable Surfboard Materials] The increased focus on eco-friendly materials is also driving further innovation in EPS surfboard construction, with bio-based epoxy resins and recycled EPS foam becoming increasingly common. As the surfing industry continues to evolve, EPS surfboards are poised to play a significant role in shaping the future of the sport.