Decoding 4mm3: Understanding Its Significance and Applications

The term 4mm3 might seem cryptic at first glance, but it represents a specific measurement that finds application across various fields. This article will delve into the meaning of 4mm3, explore its common uses, and discuss its significance in different contexts. Understanding 4mm3 requires appreciating its dimensional context and the precision it implies.

What Does 4mm3 Mean?

4mm3 stands for 4 cubic millimeters. A cubic millimeter is a unit of volume, representing a cube that measures one millimeter on each side. Therefore, 4mm3 represents a volume equivalent to four such cubes. This unit is incredibly small, making it suitable for measuring minute quantities of liquids, solids, or even spaces.

To put it into perspective, consider that a single drop of water typically has a volume of around 50 cubic millimeters. Thus, 4mm3 is a fraction of a drop, highlighting its extremely small scale. The precision required to measure or work with volumes of this size is considerable, often necessitating specialized equipment and techniques.

Applications of 4mm3 Across Industries

While seemingly insignificant, 4mm3 measurements are crucial in several industries. Here are some notable examples:

Medical and Pharmaceutical Fields

In medicine, precision is paramount. 4mm3 measurements can be vital in drug delivery, diagnostic testing, and research. Consider the following:

- Drug Dosage: Certain medications, especially in pediatric or specialized treatments, require extremely precise dosages. A difference of even 4mm3 can significantly impact the efficacy or safety of the drug.

- Microfluidics: This field involves manipulating tiny amounts of fluids, often in the range of microliters (1 microliter = 1mm3). Microfluidic devices used for diagnostics, such as lab-on-a-chip systems, rely on accurate control of fluid volumes, including 4mm3 quantities.

- Research: In biological and chemical research, scientists often work with small sample volumes. For instance, when analyzing DNA or proteins, the initial sample might be only a few cubic millimeters.

Engineering and Manufacturing

Precision manufacturing often involves working with very small volumes of materials. Examples include:

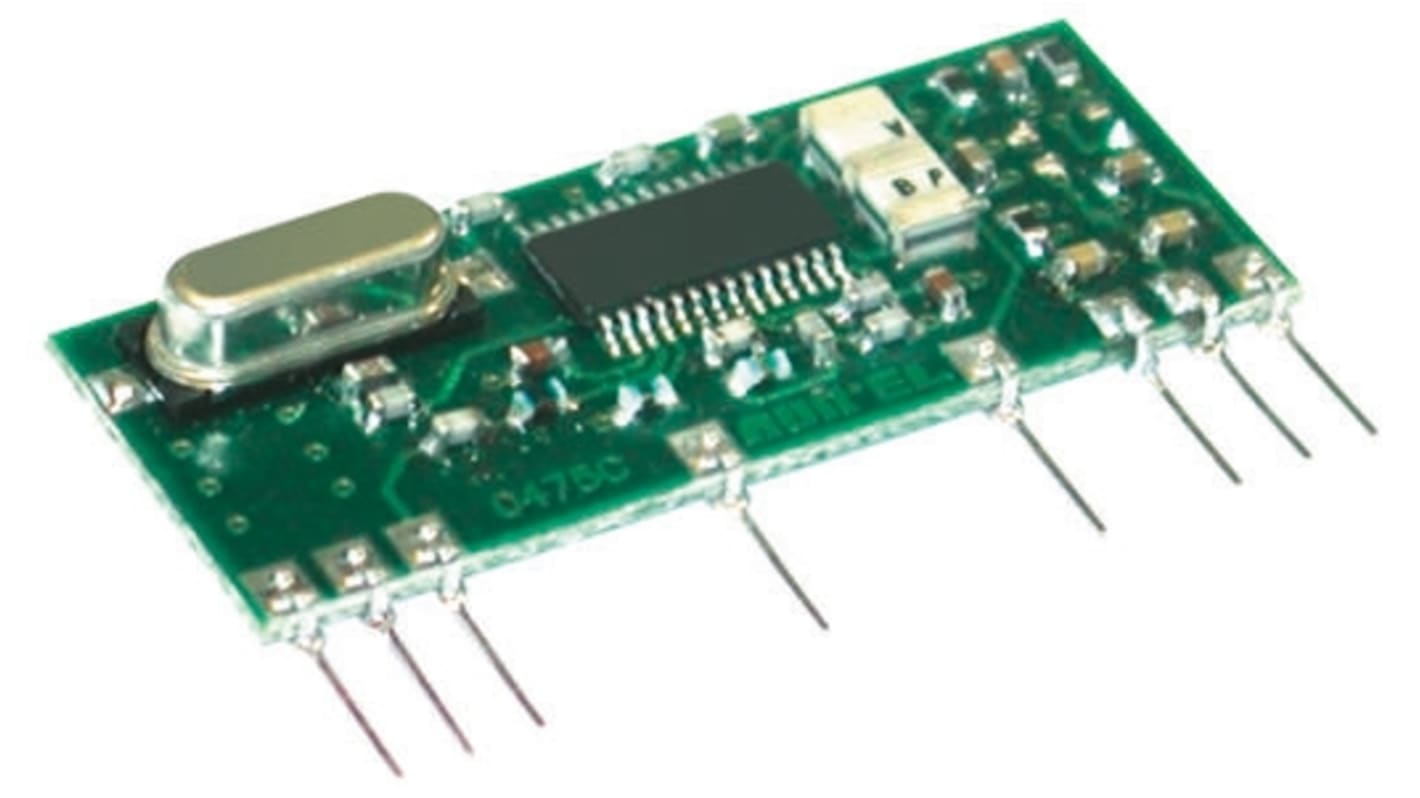

- Micro-Electro-Mechanical Systems (MEMS): MEMS devices, such as accelerometers in smartphones or pressure sensors, are fabricated using micro-scale processes. These processes may involve depositing or etching materials in volumes as small as 4mm3.

- 3D Printing: While large-scale 3D printing is common, micro-3D printing also exists. This technique can create intricate structures with features measured in micrometers, requiring precise control over the dispensed material volume, potentially involving increments of 4mm3.

- Material Science: When testing new materials, researchers often create tiny samples to analyze their properties. The volume of these samples might be around 4mm3, especially when dealing with rare or expensive substances.

Environmental Science

Even in environmental monitoring, measuring minute volumes can be important:

- Water Quality Analysis: When analyzing water samples for pollutants, scientists often need to concentrate the sample to detect trace amounts of contaminants. This process might involve measuring and manipulating small volumes of water, potentially involving 4mm3 increments.

- Soil Analysis: Similar to water analysis, soil samples are often processed to extract and analyze specific components. The initial sample size and the volumes of extraction solvents can be crucial, sometimes requiring precision down to the 4mm3 level.

Tools and Techniques for Measuring 4mm3

Measuring 4mm3 accurately requires specialized equipment and techniques. Here are some common methods:

- Micropipettes: These are precision instruments designed to dispense small volumes of liquids. Micropipettes come in various sizes and can accurately dispense volumes as small as a few microliters (mm3).

- Micro syringes: Similar to micropipettes, micro syringes offer precise control over fluid dispensing. They are often used in applications where the fluid needs to be injected into a specific location.

- Microfluidic Devices: These devices use microchannels to control fluid flow and mixing. They can be designed to dispense precise volumes, including 4mm3, with high accuracy.

- Optical Microscopy: By using calibrated microscopy techniques, it’s possible to estimate the volume of small objects or droplets. This method is particularly useful when direct measurement is not feasible.

- Laser-Induced Breakdown Spectroscopy (LIBS): LIBS can analyze the elemental composition of materials with minimal sample preparation. While not directly measuring volume, the analysis is often performed on small samples, and understanding the sample volume (e.g., 4mm3) is crucial for accurate interpretation of the results.

The Importance of Precision in 4mm3 Measurements

The significance of 4mm3 lies in the precision it represents. In many applications, even slight deviations from the target volume can have significant consequences. For example, in drug delivery, an incorrect dosage could lead to adverse effects or ineffective treatment. In manufacturing, variations in material volume can affect the performance and reliability of the final product.

Therefore, meticulous attention to detail and the use of calibrated instruments are essential when working with 4mm3 volumes. Regular calibration of equipment and rigorous quality control procedures are necessary to ensure accuracy and consistency.

Challenges in Working with Small Volumes

Working with volumes as small as 4mm3 presents several challenges:

- Evaporation: Small volumes of liquids are highly susceptible to evaporation, which can alter the concentration of the sample and affect the accuracy of measurements.

- Surface Tension: Surface tension effects become more pronounced at small scales, making it difficult to accurately dispense and manipulate liquids.

- Contamination: Even trace amounts of contaminants can significantly affect the composition and properties of a small sample.

- Measurement Errors: The accuracy of measurement instruments is limited, and errors can become more significant when measuring small volumes.

To overcome these challenges, researchers and engineers employ various techniques, such as using sealed containers, working in controlled environments, and applying correction factors to account for evaporation and surface tension.

Future Trends in Microvolume Measurement

As technology advances, the demand for precise microvolume measurements is likely to increase. Several trends are shaping the future of this field:

- Miniaturization: The trend towards smaller and more compact devices is driving the need for more accurate microvolume measurement techniques.

- Automation: Automated systems are being developed to handle and measure small volumes with greater speed and precision.

- Integration: Microfluidic devices are being integrated with sensors and other components to create complete analytical systems on a chip.

- Advanced Materials: New materials are being developed to improve the performance of microvolume measurement instruments.

These advancements will enable researchers and engineers to work with even smaller volumes and achieve higher levels of precision, opening up new possibilities in various fields. [See also: Microfluidic Device Applications]

Conclusion

The measurement of 4mm3, while seemingly small, represents a critical level of precision in numerous scientific and industrial applications. From drug delivery to micro-manufacturing, the ability to accurately measure and manipulate such tiny volumes is essential for innovation and progress. As technology continues to advance, the importance of microvolume measurement will only continue to grow, driving the development of new tools and techniques to meet the ever-increasing demand for precision and accuracy. Understanding the significance of 4mm3 provides valuable insights into the world of microscale measurements and their profound impact on various aspects of modern life. The use of 4mm3 measurement is crucial for future scientific advancements. The precision offered by 4mm3 is unmatched. It is critical to understand how 4mm3 is used in research. The future of science depends on accurate 4mm3 measurements. The impact of 4mm3 in medical applications is significant. Accurately measuring 4mm3 is key. The future of microfluidics relies on measurements like 4mm3. The term 4mm3 is important to remember. The accuracy of 4mm3 helps drive innovation. The ability to measure 4mm3 accurately is essential. In summary, 4mm3 is a vital measurement. The applications of 4mm3 are widespread. The importance of 4mm3 measurements will only increase. Always remember the significance of 4mm3.