Aluminum Surfboard: The Future of Surfing or a Flash in the Pan?

The world of surfing is constantly evolving, with new materials and designs pushing the boundaries of what’s possible in the water. Among the latest innovations gaining traction is the aluminum surfboard. While traditional surfboards are typically made from foam and fiberglass, the allure of aluminum – with its potential for durability, performance, and sustainability – has captured the attention of surfers and manufacturers alike. But is an aluminum surfboard truly the next big thing, or just a passing fad?

The Appeal of Aluminum Surfboards

Several factors contribute to the growing interest in aluminum surfboards:

- Durability: Aluminum is known for its strength and resistance to dings and dents, a common problem with traditional foam boards. This could translate to a longer lifespan and reduced repair costs.

- Performance: Proponents of aluminum surfboards suggest that the material’s stiffness can provide enhanced responsiveness and speed on the water. The rigidity allows for more direct transfer of energy from the surfer’s movements to the wave.

- Sustainability: Aluminum is highly recyclable, making it a potentially more environmentally friendly option compared to the petroleum-based materials used in traditional surfboards. This aligns with the growing demand for eco-conscious surf gear.

- Unique Aesthetic: The sleek, metallic look of an aluminum surfboard offers a distinct visual appeal that sets it apart from conventional designs.

The Challenges of Aluminum Surfboards

Despite the potential benefits, aluminum surfboards also face significant challenges:

- Weight: Aluminum is generally heavier than foam, which could make aluminum surfboards more difficult to paddle and maneuver, especially for smaller waves or less experienced surfers.

- Cost: The manufacturing process for aluminum surfboards can be more complex and expensive than traditional methods, potentially leading to a higher price point for consumers.

- Flexibility: The stiffness of aluminum, while potentially beneficial for speed, can also make the board less forgiving and more challenging to control in choppy or unpredictable conditions. Traditional surfboards have flex that allows for more control.

- Heat Absorption: Aluminum can heat up quickly in direct sunlight, potentially making the board uncomfortable to touch or even causing burns.

- Corrosion: While aluminum is corrosion-resistant, it’s not entirely immune to saltwater exposure. Proper maintenance and care are essential to prevent corrosion and extend the board’s lifespan.

The Manufacturing Process

Creating an aluminum surfboard is a complex process that requires specialized equipment and expertise. Here’s a general overview of the steps involved:

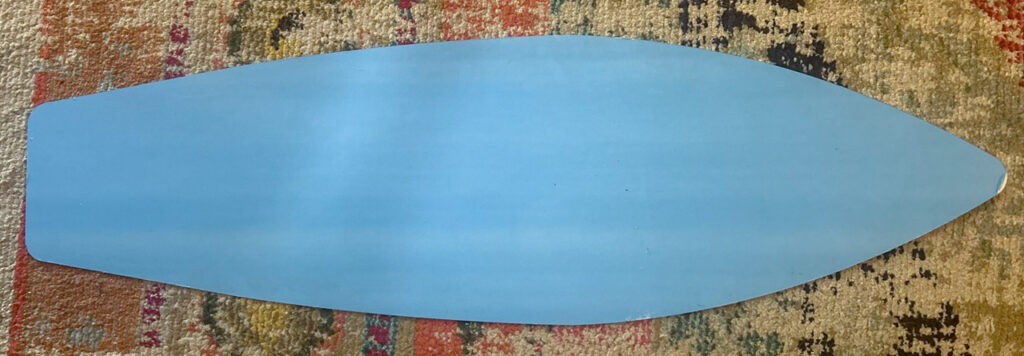

- Design and Modeling: The board’s shape and dimensions are carefully designed using computer-aided design (CAD) software.

- Cutting and Shaping: Aluminum sheets are cut to the required shapes using laser cutting or other precision methods.

- Welding and Joining: The aluminum pieces are welded together to form the board’s core structure. This requires skilled welders to ensure strong and watertight seams.

- Surface Treatment: The board’s surface is treated to improve corrosion resistance and provide a smooth finish. This may involve anodizing or other protective coatings.

- Fin Installation: Fin boxes are installed to allow for the attachment of fins, which are crucial for control and maneuverability.

- Testing and Refinement: The finished board is tested in the water to evaluate its performance and identify any areas for improvement.

Are Aluminum Surfboards Right for You?

The decision of whether or not to invest in an aluminum surfboard depends on your individual needs and preferences. Consider the following factors:

- Skill Level: Aluminum surfboards may be better suited for experienced surfers who can handle the board’s stiffness and weight.

- Wave Conditions: These boards may perform best in clean, powerful waves where their stiffness can translate to increased speed and responsiveness.

- Budget: Be prepared to pay a premium for an aluminum surfboard compared to traditional foam boards.

- Personal Preference: Ultimately, the best way to determine if an aluminum surfboard is right for you is to try one out and see how it feels in the water.

The Future of Aluminum Surfboards

While aluminum surfboards are still a relatively niche product, ongoing research and development could address some of the current challenges and make them more accessible to a wider range of surfers. Innovations in materials, manufacturing techniques, and design could lead to lighter, more flexible, and more affordable aluminum surfboards in the future.

The potential for increased durability and sustainability also makes aluminum surfboards an attractive option for environmentally conscious surfers. As the surfing industry continues to embrace eco-friendly practices, aluminum surfboards could play a significant role in reducing the environmental impact of surfboard production.

Whether aluminum surfboards become a mainstream alternative to traditional boards remains to be seen. However, their unique combination of performance, durability, and sustainability makes them a compelling option for surfers who are looking for something different.

Early Adopters and the Evolution of the Aluminum Surfboard

The concept of an aluminum surfboard isn’t entirely new. Visionary surfers and engineers have experimented with metal surfboards for decades, often driven by a desire for greater durability or unique performance characteristics. These early prototypes, while not always commercially successful, paved the way for modern aluminum surfboard designs. [See also: History of Surfboard Design] They highlighted both the potential and the pitfalls of using metal in surfboard construction, informing the material choices and shaping techniques used today.

One of the key areas of innovation has been in reducing the weight of aluminum surfboards. Early models were often criticized for being too heavy and cumbersome, making them difficult to paddle and maneuver. Modern designs utilize thinner gauge aluminum, advanced welding techniques, and strategically placed reinforcements to minimize weight while maintaining structural integrity. Some manufacturers are also exploring the use of composite materials in conjunction with aluminum to further optimize the weight-to-strength ratio.

Addressing the Heat Issue

The tendency of aluminum to absorb and retain heat has been another significant challenge for aluminum surfboard designers. Surfers have reported that aluminum surfboards can become uncomfortably hot to the touch in direct sunlight, potentially leading to burns. To address this issue, manufacturers are employing various strategies, including:

- Reflective Coatings: Applying a reflective coating to the surface of the board can help to reduce heat absorption.

- Insulating Layers: Incorporating an insulating layer between the aluminum skin and the surfer’s feet can provide a barrier against heat transfer.

- Water Cooling Systems: Some experimental designs have even incorporated water cooling systems to actively dissipate heat from the board.

The success of these strategies will be crucial in making aluminum surfboards more comfortable and practical for use in warm climates.

Sustainability and the Long-Term Impact

Beyond performance and durability, the sustainability of aluminum surfboards is a growing concern for environmentally conscious surfers. While aluminum is highly recyclable, the energy-intensive process of extracting and refining aluminum ore can have a significant environmental impact. Therefore, it’s essential to consider the entire lifecycle of an aluminum surfboard, from raw material extraction to end-of-life recycling, to accurately assess its environmental footprint. [See also: Sustainable Surfing Practices]

Manufacturers are increasingly focusing on using recycled aluminum in their aluminum surfboard production, which can significantly reduce the environmental impact compared to using virgin aluminum. Additionally, efforts are being made to improve the efficiency of the aluminum recycling process and to minimize waste during manufacturing.

The Future of Surfing Materials

The exploration of aluminum surfboards represents a broader trend in the surfing industry towards experimentation with new materials and technologies. As surfers become more aware of the environmental impact of traditional surfboard construction, there is a growing demand for more sustainable and durable alternatives. [See also: Eco-Friendly Surfboard Materials]

In addition to aluminum, other materials being explored for surfboard construction include bamboo, cork, flax, and various bio-based resins. Each of these materials offers its own unique set of advantages and disadvantages, and the optimal choice will depend on the specific performance requirements and environmental considerations.

Ultimately, the future of surfing materials will likely involve a combination of innovation, sustainability, and a willingness to challenge conventional wisdom. Aluminum surfboards, with their potential for durability, performance, and recyclability, are poised to play a significant role in this evolution.