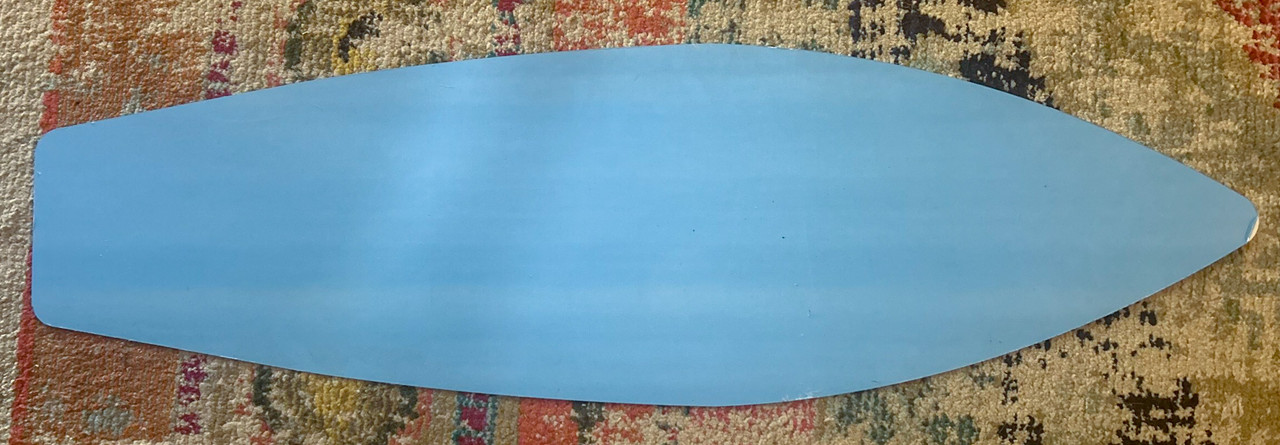

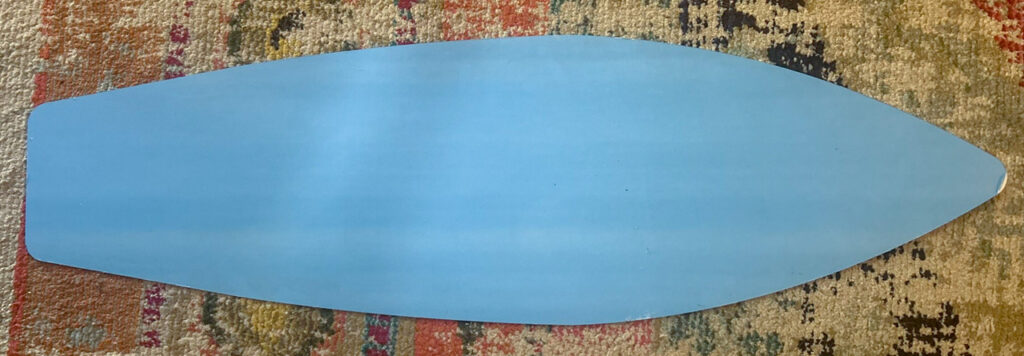

Aluminum Surfboard: A Deep Dive into Innovation and Performance

The world of surfing is constantly evolving, with innovators continually pushing the boundaries of board design and materials. Among these groundbreaking advancements is the aluminum surfboard. While traditional surfboards are typically crafted from foam and fiberglass or epoxy, the aluminum surfboard presents a unique and intriguing alternative. This article explores the history, construction, performance characteristics, and future potential of aluminum surfboards.

A Brief History of Aluminum Surfboards

The concept of using metal in surfboard construction isn’t entirely new. Experiments with metal surfboards date back several decades, though they never achieved widespread popularity. The early attempts often faced challenges related to weight, durability, and cost. However, recent advancements in materials science and manufacturing techniques have rekindled interest in aluminum surfboards. Modern versions leverage lightweight alloys and innovative designs to overcome the limitations of their predecessors.

Construction and Design of Aluminum Surfboards

The construction of an aluminum surfboard differs significantly from that of a traditional surfboard. Instead of a foam core, an aluminum surfboard typically features a hollow or partially hollow structure made from aluminum alloy sheets. These sheets are precisely shaped and welded together to create the desired board shape and volume. The use of aluminum alloys allows for a strong yet relatively lightweight construction. Key aspects of the construction include:

- Material Selection: The type of aluminum alloy used is crucial. Alloys with high strength-to-weight ratios and corrosion resistance are preferred.

- Shaping and Welding: Precise shaping and welding techniques are essential to ensure the structural integrity and hydrodynamic performance of the board.

- Surface Treatment: The surface of the aluminum surfboard is often treated with a protective coating to prevent corrosion and enhance its aesthetic appeal.

- Fin Systems: Standard fin systems can be incorporated into the design, allowing surfers to customize the board’s performance characteristics.

Performance Characteristics: What to Expect

Aluminum surfboards offer a unique riding experience compared to traditional boards. Some key performance characteristics include:

- Speed: The smooth, rigid surface of an aluminum surfboard can potentially generate greater speed compared to a traditional board, especially in clean wave conditions.

- Durability: Aluminum is a highly durable material, making aluminum surfboards resistant to dings and damage. This can be a significant advantage for surfers who frequently travel or surf in rocky environments.

- Weight: While early metal surfboards were notoriously heavy, modern aluminum surfboards can be surprisingly lightweight, especially when constructed with advanced alloys and optimized designs.

- Responsiveness: The stiffness of the aluminum can translate to a very direct and responsive feel on the water, allowing for quick turns and precise maneuvers.

- Unique Feel: Surfers often describe the ride of an aluminum surfboard as being very different from that of a traditional board. The directness and stiffness can take some getting used to, but many find it to be a rewarding experience.

Advantages and Disadvantages of Aluminum Surfboards

Like any surfboard material, aluminum surfboards have their own set of advantages and disadvantages.

Advantages:

- Durability: Exceptionally resistant to dings, dents, and other forms of damage.

- Longevity: With proper care, an aluminum surfboard can last for many years.

- Unique Riding Experience: Offers a distinct feel and performance characteristics that some surfers may prefer.

- Potential for Speed: The smooth surface can contribute to increased speed in certain wave conditions.

- Recyclability: Aluminum is a highly recyclable material, making aluminum surfboards a potentially more sustainable option than traditional boards.

Disadvantages:

- Cost: Aluminum surfboards are typically more expensive than traditional boards due to the specialized materials and manufacturing processes involved.

- Heat Conductivity: Aluminum can heat up quickly in direct sunlight, which can be uncomfortable for the surfer.

- Repair Complexity: Repairing an aluminum surfboard can be more challenging than repairing a traditional board, requiring specialized welding skills.

- Potential for Corrosion: While modern alloys are corrosion-resistant, saltwater exposure can still pose a risk if the surface coating is damaged.

- Learning Curve: The unique feel of an aluminum surfboard may require some adjustment for surfers accustomed to traditional boards.

The Future of Aluminum Surfboards

Despite the challenges, the future of aluminum surfboards looks promising. Advancements in materials science, manufacturing techniques, and design optimization are continually improving their performance and addressing the limitations of earlier models. As surfers become more open to experimenting with alternative materials and designs, aluminum surfboards may gain wider acceptance in the surfing community. The development of new alloys and coatings could further enhance their durability, reduce their weight, and mitigate the risk of corrosion. [See also: Surfboard Materials: A Comprehensive Guide]

Who Should Consider an Aluminum Surfboard?

Aluminum surfboards are not for everyone, but they may be a good fit for certain types of surfers:

- Experienced Surfers: Those who are looking for a unique riding experience and are willing to adapt to a different feel.

- Travelers: Surfers who frequently travel and need a durable board that can withstand the rigors of transportation.

- Eco-Conscious Surfers: Those who are interested in sustainable materials and reducing their environmental impact.

- Surfers in Rocky Environments: Those who surf in areas with rocky bottoms where traditional boards are easily damaged.

- Collectors: Those who appreciate innovative designs and are looking to add a unique piece to their surfboard collection.

Caring for Your Aluminum Surfboard

Proper care is essential to prolong the life of your aluminum surfboard. Here are some tips:

- Rinse Thoroughly: After each surf session, rinse the board thoroughly with fresh water to remove salt and sand.

- Store Properly: Store the board in a cool, dry place away from direct sunlight.

- Inspect Regularly: Check the board regularly for any signs of damage, such as scratches or dents.

- Repair Promptly: Address any damage promptly to prevent further corrosion or structural issues. Consult with a qualified repair technician who has experience working with aluminum.

- Apply Protective Coating: Consider applying a protective coating to the board’s surface to enhance its corrosion resistance.

Conclusion: A Promising Alternative in Surfboard Design

The aluminum surfboard represents a fascinating departure from traditional surfboard design. While it may not be for everyone, it offers a unique combination of durability, performance, and sustainability. As technology continues to advance, aluminum surfboards have the potential to become a more mainstream option for surfers seeking a different and rewarding riding experience. Whether you’re an experienced surfer looking to push the boundaries of performance or an eco-conscious rider seeking a more sustainable option, the aluminum surfboard is worth considering. Further research and development will undoubtedly shape the future of this innovative approach to surfboard construction. [See also: The Evolution of Surfboard Design]