Kevlar Used: Exploring the Versatile Applications of This Super-Strong Material

Kevlar, a name synonymous with strength and resilience, has become ubiquitous in various industries and applications. From bulletproof vests to fiber optic cables, the unique properties of this para-aramid synthetic fiber make it an invaluable material in situations demanding high tensile strength and heat resistance. This article delves into the diverse world of kevlar used, exploring its fascinating history, its key properties, and the numerous ways it enhances our lives.

The History and Discovery of Kevlar

The story of kevlar used begins with Stephanie Kwolek, a research chemist at DuPont. In 1965, while working on a new type of lightweight tire cord, Kwolek stumbled upon a unique polymer solution that, despite its cloudy and thin appearance, exhibited extraordinary strength. Initially, her discovery was met with skepticism, but further investigation revealed the remarkable potential of this new material. By 1971, DuPont had introduced Kevlar to the market, revolutionizing industries with its unparalleled properties. The development of kevlar used marked a significant advancement in material science, paving the way for innovations across various sectors.

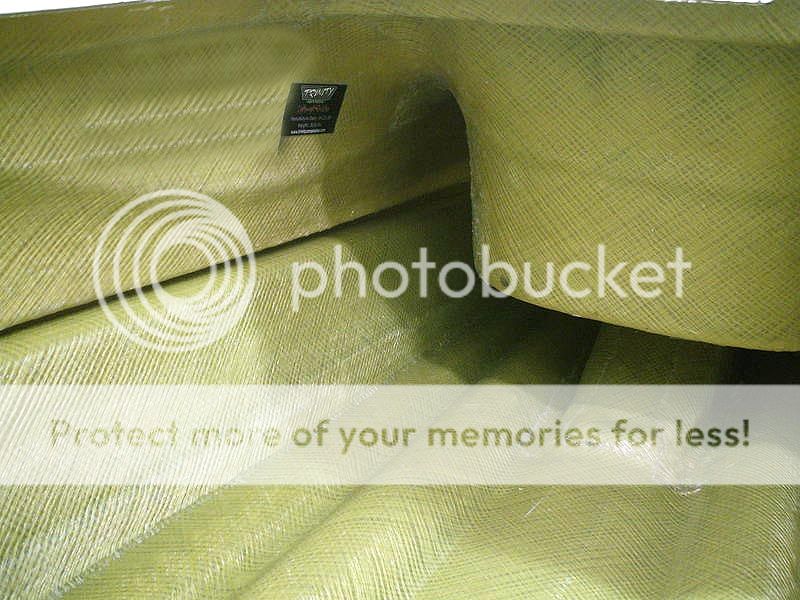

Key Properties of Kevlar

The exceptional performance of kevlar used stems from its unique molecular structure. Kevlar is a para-aramid synthetic fiber, meaning its molecules are highly ordered and aligned along the fiber axis. This arrangement contributes to its remarkable tensile strength, which is several times greater than that of steel on an equal weight basis. Furthermore, kevlar used exhibits excellent heat resistance, maintaining its structural integrity at high temperatures. Other key properties include:

- High tensile strength-to-weight ratio

- High cut resistance

- Flame resistance

- Chemical resistance

- Low elongation to break

These properties make kevlar used an ideal material for applications requiring exceptional durability and protection.

Applications of Kevlar Across Industries

Protective Gear and Armor

Perhaps the most well-known application of kevlar used is in protective gear, particularly bulletproof vests. Its high tensile strength and cut resistance make it an effective barrier against projectiles, significantly reducing the risk of injury or death. Law enforcement officers, military personnel, and security guards rely on kevlar used in body armor to protect themselves in hazardous situations. Beyond vests, kevlar used is also found in helmets, gloves, and other protective clothing, providing enhanced safety in various high-risk environments. The use of kevlar used has dramatically improved the effectiveness of personal protective equipment.

Aerospace and Automotive Industries

The lightweight and high-strength properties of kevlar used make it a valuable material in the aerospace and automotive industries. In aircraft construction, kevlar used is incorporated into composite materials to reduce weight and improve fuel efficiency. Its impact resistance also enhances the safety of aircraft structures. In the automotive industry, kevlar used is found in tires, brake pads, and other components, improving performance and durability. The incorporation of kevlar used contributes to safer and more efficient vehicles and aircraft. [See also: Advanced Composite Materials in Aerospace]

Marine Applications

The resistance of kevlar used to saltwater corrosion makes it suitable for marine applications. It is used in boat hulls, ropes, and cables, providing strength and durability in harsh marine environments. Sailcloth made with kevlar used offers superior performance compared to traditional materials, allowing for faster and more efficient sailing. The use of kevlar used in marine applications ensures the longevity and reliability of equipment exposed to the elements.

Fiber Optic Cables

Fiber optic cables, which transmit data at high speeds, require a strong and protective layer to prevent damage. Kevlar used is often incorporated into fiber optic cables to provide tensile strength and protect the delicate glass fibers from breakage. This ensures the reliable transmission of data over long distances. The integration of kevlar used is crucial for maintaining the integrity of fiber optic networks.

Sports Equipment

The demand for high-performance sports equipment has led to the increased use of kevlar used in various applications. It is found in bicycle tires, tennis rackets, skis, and other sporting goods, enhancing their strength, durability, and performance. The lightweight nature of kevlar used allows for the creation of lighter and more responsive equipment, giving athletes a competitive edge. The incorporation of kevlar used in sports equipment reflects the constant pursuit of improved performance and safety.

Medical Applications

While less common than other applications, kevlar used also finds its place in the medical field. It can be used in surgical sutures, providing high tensile strength and biocompatibility. Additionally, kevlar used can be incorporated into prosthetic devices, offering durability and support. Ongoing research explores further medical applications for this versatile material. The potential of kevlar used in medical advancements is continuously being explored.

The Future of Kevlar

The ongoing research and development in material science continue to expand the possibilities for kevlar used. Scientists are exploring new ways to enhance its properties, such as improving its resistance to UV degradation and increasing its flexibility. The development of new composite materials incorporating kevlar used promises to unlock even more applications in various industries. As technology advances, the role of kevlar used in shaping a safer and more efficient world will undoubtedly continue to grow. The future of kevlar used is bright, with ongoing innovations promising even more diverse and impactful applications.

Environmental Considerations

While kevlar used offers numerous benefits, it’s essential to consider its environmental impact. The production of synthetic fibers like Kevlar involves energy-intensive processes and the use of potentially harmful chemicals. Recycling kevlar used can be challenging due to its complex structure and the difficulty in separating it from composite materials. However, efforts are underway to develop more sustainable production methods and recycling technologies for kevlar used. A focus on responsible manufacturing and end-of-life management is crucial for minimizing the environmental footprint of kevlar used. [See also: Sustainable Manufacturing Practices]

Conclusion

Kevlar used has revolutionized numerous industries with its exceptional strength, heat resistance, and versatility. From protecting lives in bulletproof vests to enhancing the performance of sports equipment, its applications are vast and varied. As technology continues to evolve, the demand for high-performance materials like kevlar used will likely increase, driving further innovation and expanding its role in shaping a safer and more efficient future. Understanding the properties and applications of kevlar used is crucial for appreciating its significance in modern society. The impact of kevlar used on our lives is undeniable, and its continued development promises even greater advancements in the years to come. The journey of kevlar used, from a laboratory discovery to a ubiquitous material, is a testament to the power of scientific innovation.