Kevlar Used: Exploring the Versatile Applications of Aramid Fiber

Kevlar, a name synonymous with strength and resilience, is a para-aramid synthetic fiber, five times stronger than steel by weight. Developed by Stephanie Kwolek at DuPont in 1965, and first commercially kevlar used in the early 1970s, it quickly gained recognition for its exceptional tensile strength and heat resistance. Today, kevlar used is not just a material; it’s a solution, finding applications across a diverse range of industries. This article delves into the fascinating world of kevlar used, exploring its properties, manufacturing process, and the myriad ways in which it enhances our lives.

The Science Behind Kevlar

The secret to Kevlar’s remarkable strength lies in its molecular structure. It’s a polymer composed of long chains of molecules oriented in a parallel fashion. These chains are held together by strong hydrogen bonds, creating a highly ordered and crystalline structure. This arrangement allows Kevlar to withstand tremendous tensile forces, making it exceptionally resistant to stretching and tearing. Furthermore, kevlar used exhibits excellent thermal stability, maintaining its properties at high temperatures. It also resists chemical degradation from many common substances.

Key Properties of Kevlar

- High tensile strength-to-weight ratio

- High cut resistance

- Flame resistant

- Non-conductive

- Chemical resistant

- Low thermal shrinkage

Manufacturing Kevlar

The manufacturing process of Kevlar is complex, involving the polymerization of para-phenylenediamine and terephthaloyl chloride in a solution. This reaction produces a liquid-crystalline polymer, which is then spun into fibers. The spinning process aligns the polymer chains, further enhancing the fiber’s strength. The resulting fibers are then washed, dried, and wound onto bobbins. Different grades of Kevlar are produced by varying the spinning and processing parameters, tailoring the material’s properties for specific applications. Because of its unique manufacturing requirements, kevlar used is relatively expensive compared to other synthetic fibers.

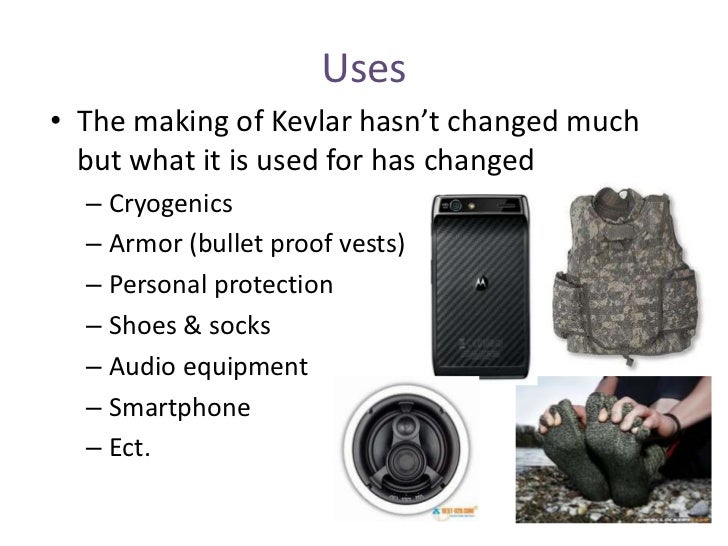

Applications of Kevlar: Where is Kevlar Used?

The versatility of Kevlar allows it to be kevlar used in a wide array of applications, ranging from protective gear to aerospace components. Its unique combination of strength, heat resistance, and lightweight properties makes it an ideal material for demanding environments.

Protective Gear

Perhaps the most well-known application of Kevlar is in body armor. Bulletproof vests made with kevlar used provide crucial protection for law enforcement officers, military personnel, and security guards. The tightly woven fibers of Kevlar absorb and dissipate the energy of a bullet, preventing it from penetrating the vest. [See also: Body Armor Evolution: A Historical Perspective] Beyond bulletproof vests, kevlar used is also found in cut-resistant gloves, helmets, and other protective clothing used in industries such as construction, manufacturing, and law enforcement. These items protect workers from sharp objects, impacts, and other hazards.

Aerospace

In the aerospace industry, weight is a critical factor. Kevlar’s high strength-to-weight ratio makes it an excellent material for aircraft components. It is kevlar used in aircraft panels, fuselage components, and even in the tires of aircraft landing gear. The use of Kevlar reduces the overall weight of the aircraft, improving fuel efficiency and performance. Furthermore, kevlar used is resistant to vibration and fatigue, making it suitable for long-term use in demanding aerospace environments.

Automotive

The automotive industry also benefits from the properties of Kevlar. It’s kevlar used in tires to improve their strength and durability, reducing the risk of punctures and blowouts. Kevlar is also found in brake pads, where its heat resistance helps to prevent brake fade. In high-performance vehicles, kevlar used can be incorporated into clutch linings and other components to enhance their performance and longevity. The lightweight nature of kevlar used also contributes to improved fuel economy.

Sports Equipment

Kevlar’s strength and lightness make it a valuable material in various sports equipment. It’s kevlar used in racing sails to enhance their performance and durability. The material is also found in bicycle tires, providing puncture resistance and improving handling. Furthermore, kevlar used is incorporated into protective gear for sports such as hockey, football, and motorcycle racing, offering impact protection and reducing the risk of injuries.

Ropes and Cables

The high tensile strength of Kevlar makes it ideal for ropes and cables used in demanding applications. It’s kevlar used in mooring lines for ships, towing cables, and lifting slings. Kevlar ropes are also used in rescue operations, where their strength and lightweight properties are crucial. Because kevlar used does not corrode or rust, it is ideal for marine environments.

Fiber Optics

Kevlar is used as a strength member in fiber optic cables. It provides protection to the delicate glass fibers, preventing them from being damaged during installation and use. The lightweight nature of kevlar used also makes it easier to handle and install fiber optic cables, especially in long-distance applications.

Medical Applications

While less common, Kevlar finds applications in the medical field. It has been explored for use in surgical implants and prosthetic devices due to its biocompatibility and strength. Research is ongoing to explore new ways to utilize the properties of kevlar used in medical applications.

The Future of Kevlar

The future of Kevlar looks promising, with ongoing research and development focused on improving its properties and expanding its applications. Researchers are exploring new ways to enhance its strength, heat resistance, and chemical resistance. New grades of kevlar used are being developed to meet the specific needs of emerging industries, such as renewable energy and nanotechnology. As technology advances, we can expect to see even more innovative uses for this remarkable material.

Sustainability Considerations

While Kevlar offers numerous benefits, it is important to consider its environmental impact. The manufacturing process requires significant energy and resources, and the disposal of kevlar used products can be challenging. Efforts are underway to develop more sustainable manufacturing processes and to find ways to recycle Kevlar waste. As environmental awareness grows, the focus on sustainability will likely drive further innovation in the production and use of Kevlar.

Conclusion

Kevlar used is a remarkable material that has revolutionized numerous industries. Its exceptional strength, heat resistance, and lightweight properties make it an indispensable component in protective gear, aerospace components, automotive parts, sports equipment, and many other applications. From safeguarding lives in bulletproof vests to enhancing the performance of aircraft and automobiles, Kevlar has proven its worth time and again. As technology continues to evolve, we can expect to see even more innovative uses for this versatile aramid fiber, further solidifying its place as a cornerstone of modern engineering and materials science. The future of kevlar used is bright, driven by ongoing research, sustainable practices, and the ever-increasing demand for high-performance materials.